CS Symons cone crusher occupies an important position in the crushing industry with its high-efficiency crushing capacity, easy adjustment and maintenance, high reliability and durability, low operating cost, and wide adaptability.

• Multi-chamber selection: standard type (medium crushing), short head type (fine crushing), finished product particle size 3-50mm adjustable.

Symons cone crusher

Symons cone crusher price

Symons crusher

CS series cone crusher

CS Symons cone crusher: mechanical spring system, simple structure; medium-hard ore, limited budget projects; low maintenance cost (strong spare parts versatility).

Symons Cone Crusher is widely used in the secondary and fine crushing of medium-hard and high-hardness ores, especially in the crushing of iron ore, copper ore, granite, basalt, etc. It is also an ideal equipment for the production of machine-made sand and the preparation of high-grade concrete aggregates.

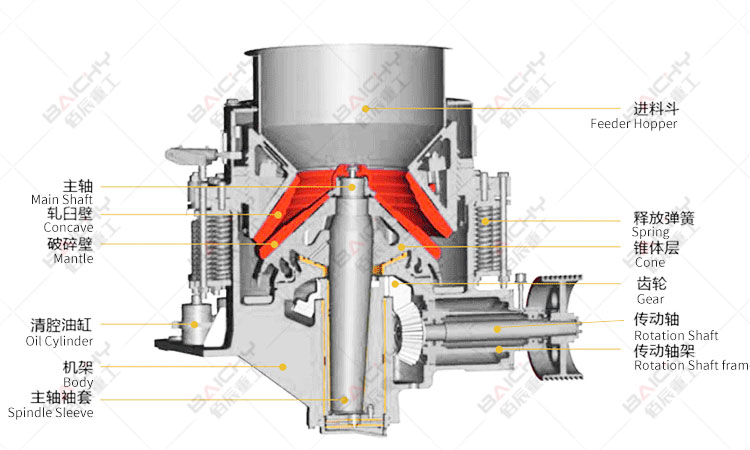

Symons cone crusher adopts the classic mechanical structure of fixed main shaft + eccentric sleeve drive to ensure high stability and long life.

Crushing chamber: Provides a variety of chamber types, such as standard type and short head type, to adapt to different feed particle sizes (coarse crushing/medium crushing/fine crushing).

Main shaft system: Fixed main shaft design, through the rotation of the eccentric sleeve, drives the moving cone to swing in a circle to form a continuous crushing stroke.

Overload protection: Using mechanical springs or hydraulic devices, automatically unloading pressure when encountering unbreakable objects such as iron blocks to protect core components.

Lubrication system: Independent circulation oil circuit to reduce friction between gears and bearings to ensure stable operation under high temperature conditions.

| Model | Cavity Type | Crushing Cone Diameter(mm) |

Adjusting Range of Discharge Opening(mm) |

Max feeding size (mm) |

Capacity (t/h) |

Motor (kw) |

Overall size (mm) |

| CS75 | Coarse | 900(3') | 25-38 | 150 | 59-163 | 75 | 2450×1820×2100 |

| CS75 | Medium | 900(3') | 13-38 | 85 | 45-91 | 75 | 2450×1820×2100 |

| CS75 | Fine | 900(3') | 6-22 | 35 | 27-90 | 75 | 2450×1820×2100 |

| CS110 | Coarse | 1200(4') | 15-50 | 180 | 110-250 | 110 | 2485×2050×2445 |

| CS110 | Medium | 1200(4') | 10-38 | 130 | 80-180 | 110 | 2485×2050×2445 |

| CS110 | Fine | 1200(4') | 10-31 | 90 | 63-140 | 110 | 2485×2050×2445 |

| CS160 | Coarse | 1295(4 1/4') | 19-50 | 205 | 172-349 | 132 | 2885×2320×2855 |

| CS160 | Medium | 1295(4 1/4') | 16-38 | 178 | 132-253 | 132 | 2885×2320×2855 |

| CS160 | Fine | 1295(4 1/4') | 13-31 | 115 | 109-181 | 132 | 2885×2320×2855 |

| CS220 | Coarse | 1400(4 1/2') | 30-60 | 235 | 210-530 | 220 | 3153×2358×2750 |

| CS220 | Medium | 1400(4 1/2') | 22-45 | 180 | 180-475 | 220 | 3153×2358×2750 |

| CS220 | Fine | 1400(4 1/2') | 19-40 | 100 | 130-260 | 220 | 3153×2358×2750 |

| CS250 | Coarse | 1650(5 1/2') | 30-60 | 228 | 299-635 | 250 | 3410×2620×3350 |

| CS250 | Medium | 1650(5 1/2') | 25-50 | 205 | 258-417 | 250 | 3410×2620×3350 |

| CS250 | Fine | 1650(5 1/2') | 20-45 | 178 | 181-327 | 250 | 3410×2620×3350 |

| CS315 | Coarse | 2135(7') | 31-64 | 314 | 1125-1814 | 400 | 4613×3302×4638 |

| CS315 | Medium | 2135(7') | 25-51 | 284 | 862-1424 | 400 | 4613×3302×4638 |

| CS315 | Fine | 2135(7') | 19-38 | 236 | 544-1034 | 400 | 4613×3302×4638 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery