For the project transformation, the fine jaw crusher in the original crushing line was replaced with a PYB900 cone crusher. Considering the output requirement of 30-40TPH and the need for three specifications of discharge, the following is a detailed analysis and suggestions for this transformation:

1. Parameters and advantages of PYB900 cone crusher

• Output: The output range of the PYB900 cone crusher is 50-90t/h, which far exceeds the 30-40t/h output required by the project.

• Crushing effect: PYB900 cone crusher adopts the principle of lamination crushing. The particle size of the crushed product is relatively uniform and in a cubic shape. The wear of the working surface of the moving cone is also relatively uniform. This crushing effect helps to improve the quality of the product.

• Flexible adjustment: The discharge port size of the PYB900 cone crusher can be adjusted in the range of 15-50mm, which means that the discharge specifications can be adjusted as needed to meet different production needs.

2. Configuration of the crushing line after replacement

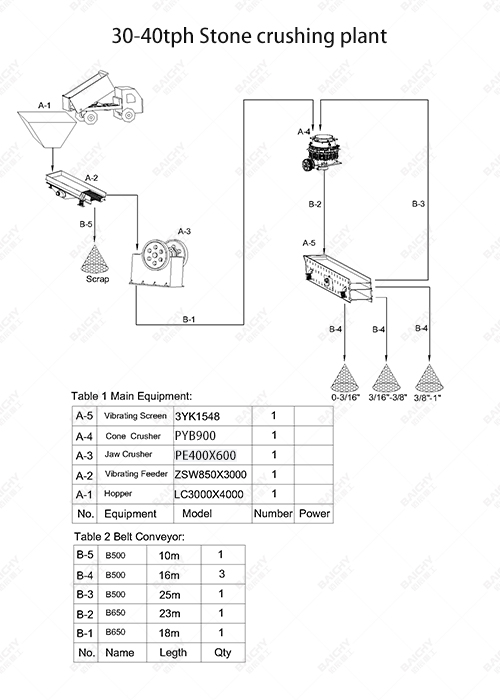

The configuration of the crushing line after replacement is jaw crusher + PYB900 cone crusher + vibrating screen. This configuration retains the original jaw crusher and vibrating screen but replaces the fine jaw crusher with a PYB900 cone crusher.

Jaw crusher: As a primary crushing device, the jaw crusher is mainly used to crush large pieces of material to a particle size suitable for entering the cone crusher.

PYB900 cone crusher: As a secondary crushing device, the PYB900 cone crusher further crushes the material after jaw crushing to the required particle size. Due to the large output, good crushing effect, and flexible adjustment of the PYB900 cone crusher, it is very suitable as the secondary crushing equipment for this project.

Vibrating screen: The vibrating screen is used to screen the material after the cone crusher and separate the finished products of different specifications. According to the project requirements, multiple layers of screens can be set to produce three different specifications of finished products at the same time.