PE 750x1060 jaw crusher is a widely used mining equipment, its main features are as follows:

1. Feed port size: The feed port size of this crusher is 750x1060mm, which is suitable for processing larger stones.

2. Feeding particle size: The feeding particle size is usually controlled below 630mm to ensure that the equipment can perform crushing work normally and effectively.

3. Crushing capacity: PE 750x1060 jaw crusher is mainly used for head crushing and coarse crushing operations. The discharge particle size can be freely adjusted between 50-180mm. Its production capacity ranges from 110-320 tons per hour, and the specific output may vary depending on material characteristics, operating methods, and other factors.

4. Power configuration: This crusher is usually equipped with a 110kw motor and a main shaft speed of 254 rpm to ensure that the equipment has sufficient crushing capacity and working efficiency.

5. Application fields: PE 750x1060 jaw crusher is widely used in mining, construction, highway, railway, and other industries. It is mainly used to crush ores, rocks, construction waste, and other materials of various hardness.

There are many types and options for stone crushing equipment with an output of 100-150t/h. Here are some of the common devices:

1. Hydraulic cone crusher: There are many types of hydraulic cone crushers, including single-cylinder cone crushers, multi-cylinder cone crushers, fully hydraulic cone crushers, and compound cone crushers. This equipment combines high-performance crushing cavities and high crushing frequency to greatly improve the crushing efficiency. The hydraulic chamber can realize various functions such as iron protection, chamber cleaning, and lubrication. The crushed products are mostly cubic structures with a little needle and flake content.

2. Tire-type screening mobile crushing station: This equipment is mainly used for processing materials that often need to be moved in metallurgy, chemical industry, building materials, mining, etc., especially for the processing of mobile materials such as roads, railways, water, and electricity. It is flexible, convenient, and highly maneuverable, can save a lot of infrastructure and migration costs, and can reduce material transportation costs.

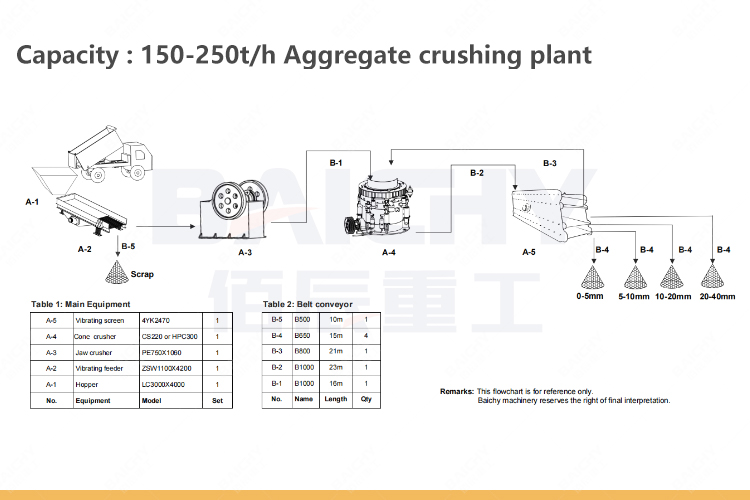

3. Jaw crusher: For example, the 750x1060 jaw crusher is mainly used for head crushing and coarse crushing operations. The discharge particle size can be freely adjusted between 50-180mm. Its hourly output is between 110-320 tons, which can meet the production demand of 150-250t/h.