Dewatering screen - Vibrating screen machine: Efficient solid-liquid separation solution

What is a dewatering screen (vibrating screen machine)?

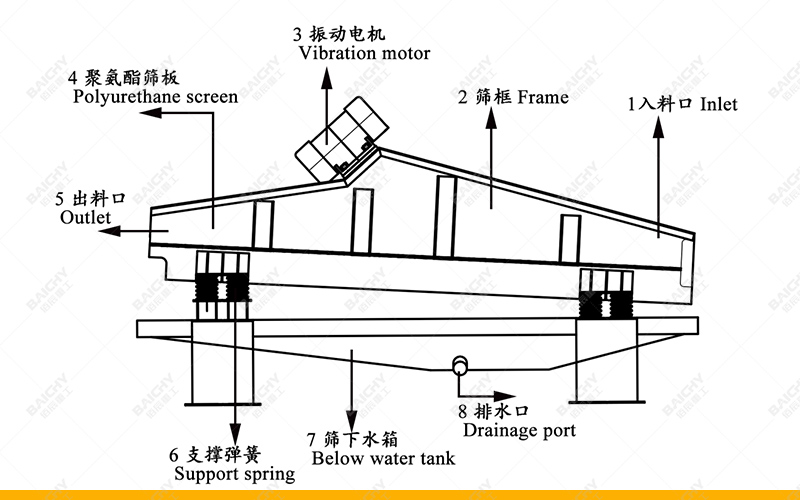

Dewatering screen (also known as vibrating screen machine) is a device that uses a vibrating motor to drive the screen surface for efficient solid-liquid separation. It is widely used in mining, sand and gravel aggregates, environmental sludge treatment, tailings dry discharge, sewage treatment and other fields. Its core function is to quickly remove moisture from materials through high-frequency vibration, improve dry discharge efficiency, and reduce transportation and storage costs.

Working principle of dewatering screen (vibrating screen machine)

The dewatering screen uses a vibrating motor or an exciter as a power source to make the screen surface vibrate at high frequency. The material keeps rolling and jumping on the screen surface, and the water is discharged through the screen holes. The solid particles are transported forward along the screen surface, and finally the dry material and water are separated.

Core advantages:

✔ Efficient dehydration: large processing capacity, high dehydration efficiency, suitable for materials with high moisture content.

✔ Energy saving and environmental protection: low energy consumption design, reduce water resource waste, and meet environmental protection requirements.

✔ Durable and reliable: Made of high-quality steel + wear-resistant screen, it has a long service life and low maintenance cost.

✔ Flexible adaptation: The screen aperture and vibration frequency can be customized to meet the needs of different industries.

Main applications of dewatering screen (vibrating screen machine)

• Dry discharge of mining tailings: used for dewatering of tailings such as gold mines, iron mines, copper mines, etc. to reduce the pressure of tailings ponds.

• Sand and gravel aggregate cleaning and dehydration: In the machine-made sand and water-washed sand production lines, the moisture content standard of the finished sand is improved.

• Environmental sludge treatment: suitable for sludge dehydration in sewage treatment plants, coal washing plants, etc., which is convenient for subsequent transportation and disposal.

• Chemical/food industry: used for dehydration and screening of fine materials, such as starch, salts, chemical raw materials, etc.

How to choose a suitable dewatering screen (vibrating screen machine)?

When purchasing a dewatering screen, the following factors should be considered:

• Material properties: particle size, moisture content, viscosity, etc.

• Processing capacity requirements: select a suitable model according to the output (such as 10-200 tons/hour).

• Screen material: polyurethane, stainless steel, rubber, etc. Different materials affect wear resistance and life.

• Vibration mode: linear vibration, circular vibration, high-frequency vibration, etc. Different modes affect the dewatering effect.

Recommended models:

• High-frequency dewatering screen: suitable for fine-grained materials with high dewatering efficiency.

• Linear vibration dewatering screen: large processing capacity, suitable for dewatering of coarse particles such as sand, gravel, and tailings.

• Multi-stage dewatering screen: multi-stage screening, suitable for complex material dewatering needs.

Baichy Heavy Industry Dewatering Screen (Vibrating Screen Machine) Core Competitiveness

✔ German technology vibration motor: stable operation, low noise, life of up to 10 years+.

✔ Intelligent control system: supports variable frequency adjustment to adapt to different working conditions.

✔ Customized service: Provide free solution design to meet special industry needs.

✔ Global case verification: Has been successfully applied to 1000+ mining, environmental protection, and sand and gravel projects.

Consult now: If you need a dewatering screen (vibrating screen machine) selection or quotation, please contact our professional team and provide free technical solutions!

Dewatering screen (vibrating screen machine) is an indispensable and efficient dewatering equipment in modern chemical, mining, environmental protection and other industries. Choosing the right model and brand can greatly improve production efficiency and reduce operating costs. Baichy Heavy Industry relies on advanced technology and rich experience to provide you with a cost-effective dewatering screen solution, welcome to inquire!