Granite, as a high-hardness rock, is a core aggregate raw material in the construction and infrastructure fields. However, its high wear resistance places stringent requirements on crushing equipment.

How to choose a suitable granite crusher? How to design the crushing process? How to control investment costs?

Stone Crushing Plant PDF, Download ↓↓↓

This article will systematically analyze the entire rock crushing process and provide practical price references to help you accurately plan your production.

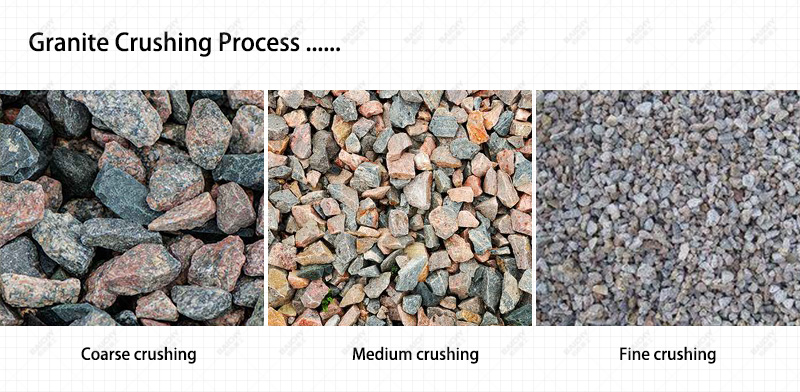

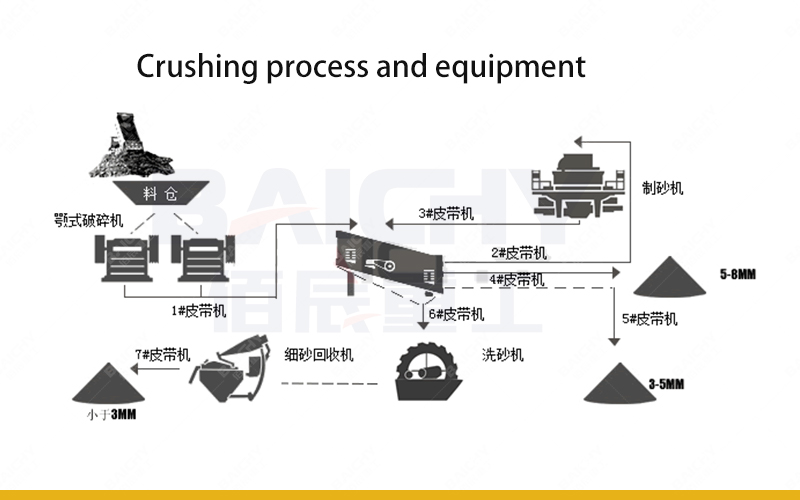

I. Core Components of the Granite Crushing Process

1. Coarse Crushing Stage (Jaw Crusher)

Large granite pieces (≤1500mm) are fed into the jaw crusher via a vibrating feeder and crushed to ≤200mm medium material. The jaw crusher has a robust structure and is suitable for the primary crushing of high-hardness materials.

2. Medium and Fine Crushing Stage (Cone Crusher/Impact Crusher)

• Cone Crusher: Suitable for high-strength crushing; the layering principle reduces wear, resulting in excellent finished particle shape.

• Impact Crusher: Primarily uses impact crushing; suitable for medium to low-hardness rocks; lower power consumption.

3. Shaping and Screening (Impact Crusher + Vibrating Screen)

The vertical shaft impact crusher shapes the crushed stone, improving aggregate quality; the vibrating screen grades the finished product into 0-5mm, 5-10mm, and 10-20mm sizes.

II. Factors Affecting the Price of Granite Crusher

1. Equipment Type and Specifications

• Jaw Crusher (100,000-1,000,000 RMB): Larger models have higher processing capacity;

• Cone Crusher (300,000-2,000,000 RMB): Hydraulic technology and automation level affect the price;

• Mobile Crushing Plant (1,000,000-5,000,000 RMB): Integrated design, high flexibility.

2. Production Line Configuration

• Fixed Production Line: Low investment (500,000-3,000,000 RMB), suitable for long-term large-scale production;

• Mobile Production Line: High investment (over 2,000,000 RMB), convenient relocation, suitable for short-term projects.

3. Energy Consumption and Maintenance Costs

The energy consumption of a cone crusher is lower than that of an impact crusher, but the replacement cost of wear parts is higher. It is recommended to select wear-resistant materials based on the SiO₂ content of the granite.

III. Optimization Suggestions and Case References

• Energy-saving solution: Configure a frequency converter to control the feeding speed, reducing power consumption by 15%;

• Typical case: A granite mine uses a three-stage crushing system of "jaw crusher + cone crusher + impact crusher," with an hourly output of 200 tons, an equipment investment of approximately 1.8 million yuan, and a payback period of <1.5 years.

Rational selection of granite crushers and process design can significantly improve crushing efficiency and control costs. It is recommended to customize a scientific production line solution based on raw material characteristics, capacity requirements, and budget. For specific equipment quotations or process design, please consult with a professional engineer one-on-one!