PE500x750 Jaw Crusher: Feed port size (width × length): 500 × 750mm, maximum feed size: ≤425mm, discharge port adjustment range: 50-120mm, discharge port size is adjustable.

Capacity: 80-100tph

Application: The finished materials are mainly supplied to local concrete mixing plants and rural road construction.

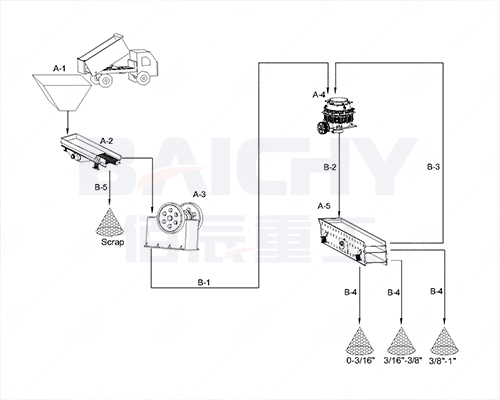

Equipment: ZSW 8530 feeder vibration, PE 500x750 jaw crusher, CS75 Simmons cone crusher, 4YK1548 vibrating screen

Process flow of 80-100tph granite crushing plant

1. Coarse crushing: The granite raw materials in the large silo are fed into the PE500x750 jaw crusher for coarse crushing, and the raw materials are crushed to particles of a certain size. During this process, the feed particle size of the jaw crusher can reach less than 1200 mm, and the discharge range is controllable.

2. Medium crushing: The coarsely crushed granite particles are fed into the CS75 cone crusher for secondary medium crushing. The cone crusher has high crushing strength and uniform discharge and can crush granite to less than 560mm.

3. Fine crushing: For granite particles that require finer particle size, an impact sand-making machine can be used for fine crushing. The impact sand-making machine can process the material into finished products with a fineness of 0-5 mm, meeting the user's demand for uniform sand.

4. Vibration screening: The crushed granite particles are screened through the 4YK1548 vibrating screen and classified according to different specifications. The vibrating screen screens the material into finished products of different specifications through a strong excitation force and is not easy to clog.

Note: If the feed size is less than 200mm, it can be directly crushed by the Simmons cone crusher to avoid primary crushing.

The crushing production line configured by Baichy has efficient production capacity

1. High production capacity: The design capacity of the production line reaches 80-100 t/h, which can meet the needs of large-scale production and effectively improve production efficiency.

2. Fast processing: By optimizing the process flow and equipment configuration, large pieces of granite can be quickly crushed into products of the required particle size, reducing the production cycle.

High-quality crushing effect

1. Uniform particle size: Crushing equipment such as cone crushers and impact sand-making machines can accurately control the discharge particle size to ensure uniform product particle size and meet different usage requirements.

2. High yield rate: Through reasonable crushing technology and screening equipment, the yield rate can be effectively improved and the generation of waste can be reduced.

Flexible adaptability

1. Strong adaptability: The production line can handle granite of different hardness and water content, has strong adaptability, and can be widely used on various occasions.

2. Adjustability: Crushing equipment such as cone crushers have an adjustable discharge port design, which can flexibly adjust the discharge particle size according to production needs.

Low energy consumption and environmental protection

1. Energy saving and consumption reduction: Reduce energy consumption and production costs by optimizing equipment configuration and process flow.

2. Environmentally friendly production: Adopt closed production to reduce dust and noise emissions, in line with national environmental protection requirements.

PE500x750 Jaw Crusher: Feed port size (width × length): 500 × 750mm, maximum feed size: ≤425mm, discharge port adjustment range: 50-120mm, discharge port size is adjustable.