The 150-200tph limestone crushing production line has significant advantages, which are reflected in many aspects such as production efficiency, product quality, equipment configuration, and environmental protection.

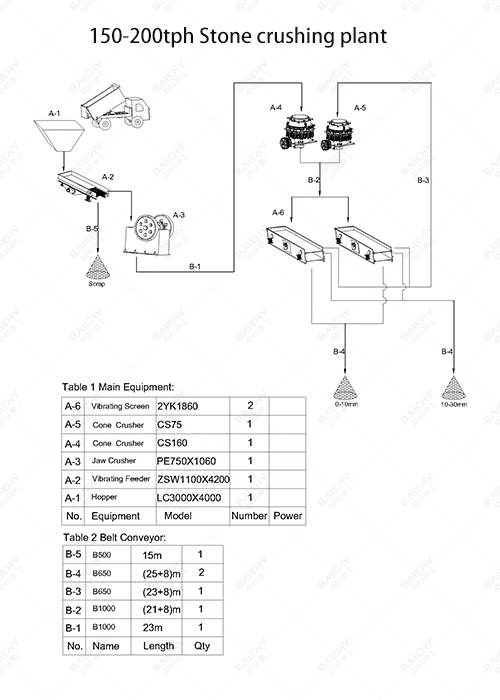

1. The equipment on the production line, such as jaw crusher, impact crusher, etc., has been optimized and designed to have high crushing efficiency and can achieve fast and stable crushing operations.

2. After multi-stage crushing and screening processes, the particle size of limestone is accurately controlled and can meet the needs of different particle sizes.

3. The production line consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, and other equipment. It is reasonably configured and can meet various process requirements of limestone crushing.

4. The low failure rate and long life of the equipment reduce maintenance costs and downtime and improve the stability and reliability of the production line.

5. The production line can also be adjusted and optimized according to different raw materials and process requirements to meet the production needs of different customers.

The 150-200tph limestone crushing production line has the advantages of efficient production capacity, product quality assurance, reasonable equipment configuration, superior environmental performance, strong flexibility and adaptability, and significant economic benefits.