In the quarrying, mining, and aggregate production industries, we encounter the terms "rock," "ore," and "mineral" daily. While often used interchangeably, their underlying meanings are fundamentally different.

Understanding these differences is the first step in selecting the right aggregate crusher for your project and is crucial in determining production efficiency, product quality, and operating costs.

I. Basic Concepts: Clarifying the Differences Between Rock, Ore, and Mineral

• Mineral: A naturally formed inorganic solid with a fixed chemical composition and unique crystal structure. It is the basic unit that makes up rocks and ores. For example, quartz, feldspar, calcite, and pyrite are all minerals.

• Rock: A natural aggregate composed of one or more minerals. Rocks can be classified into three main categories based on their formation process: igneous rocks (such as granite), sedimentary rocks (such as limestone), and metamorphic rocks (such as marble).

• Ore: A special type of rock containing economically valuable minerals that can be mined and utilized. If a rock contains metals or useful minerals that are not economically mineable, it can only be called a rock, not an ore. For example, hematite rock containing sufficient iron is iron ore.

Simply put: minerals make up rocks, but rocks with economic value are ore.

II. How to Choose an Aggregate Crusher Based on Characteristics?

Different material characteristics (such as hardness, abrasiveness, moisture content, and required output particle size) directly determine which type of crusher should be selected.

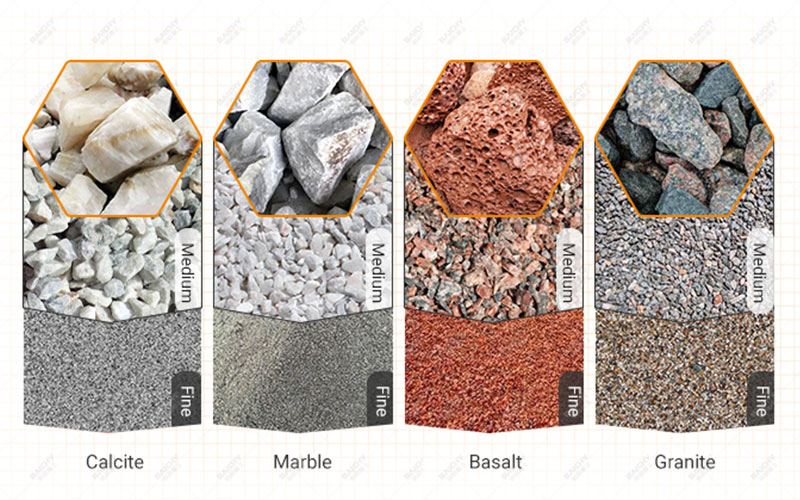

1. Crushing Hard, Highly Abrasive Rocks (such as granite and basalt)

◦ Characteristics: High hardness, high abrasiveness, resulting in significant wear on the wear-resistant parts of the crushing equipment.

◦ Recommended Equipment: Jaw crusher (coarse crushing) + cone crusher (medium and fine crushing). This combination is the gold standard for processing highly abrasive materials. The cone crusher uses a layered crushing principle, has high wear resistance, and can stably produce high-quality aggregates.

2. Crushing medium-hardness, low-abrasive rocks (e.g., limestone, gypsum)

◦ Characteristics: Low hardness, low abrasiveness, may require high particle shape.

◦ Recommended equipment: Jaw crusher (coarse crushing) + impact crusher (medium and fine crushing). Impact crushers utilize impact energy, producing good cubic particle shape, and typically have lower equipment investment and operating costs than cone crushers.

3. Processing metallic ores (e.g., iron ore, copper ore)

◦ Characteristics: Large variations in hardness, often accompanied by extremely high abrasiveness, and requires the "liberation" of valuable minerals from gangue for subsequent beneficiation.

◦ Recommended equipment: Jaw crusher/gyratory crusher (coarse crushing) + cone crusher (medium and fine crushing). The key is to achieve efficient selective crushing to ensure uniform particle size, preparing for grinding and beneficiation. The wear resistance of the equipment is a primary consideration.

4. Handling Sticky or Wet Materials

◦ Characteristics: Prone to clogging the crushing chamber, affecting production efficiency.

◦ Precautions: Impact crushers should be selected with caution. Cone crushers or roller crushers are preferable, and pre-screening or drying measures should be considered at the feed end.

Choosing an aggregate crusher is not a "one-size-fits-all" approach. From basic rock crushing to complex ore processing, the right choice begins with a deep understanding of the material itself. Identify the type of rock or ore your feed, analyze its hardness, abrasiveness, moisture content, and other key indicators, and combine this with your output and product particle size requirements to match the most powerful crushing "tool" for your business.

Consult our expert team now for personalized crushing solutions that will dramatically improve your production efficiency!