In the mining and processing of rock gold ore, CIP (Carbon-In-Pulse) and CIL (Carbon-Leach-In) are two mainstream gold extraction technologies. They achieve efficient recovery by adsorbing gold elements with activated carbon, and are particularly suitable for processing low-grade ores. This article will delve into the differences in the process flow between CIP and CIL, and focus on the selection and optimization schemes of key equipment.

I. Overview of CIP and CIL Technologies

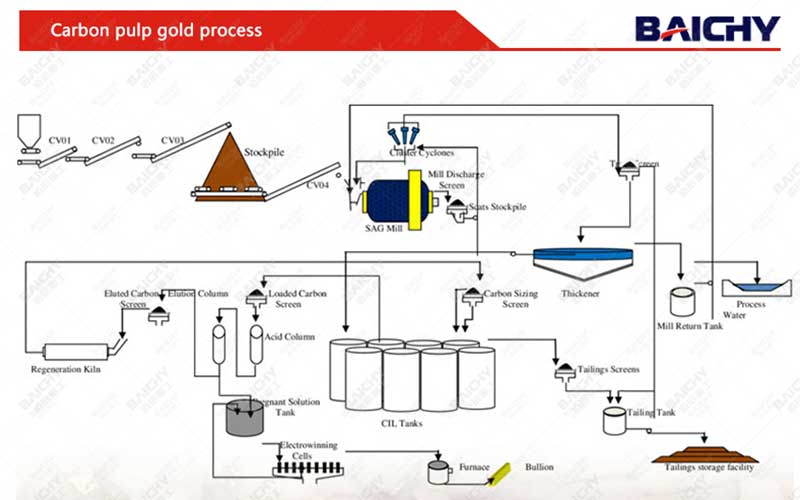

1. CIP (Carbon-In-Pulse): Leaching precedes adsorption. The gold ore slurry undergoes cyanidation in the leaching tank before entering the adsorption tank to combine with activated carbon.

2. CIL (Carbon-Leach-In): Leaching and adsorption occur simultaneously, reducing process steps and suitable for high-mud ores or complex ores.

• Advantages Comparison: CIL requires lower investment; CIP is suitable for ores with fluctuating gold content.

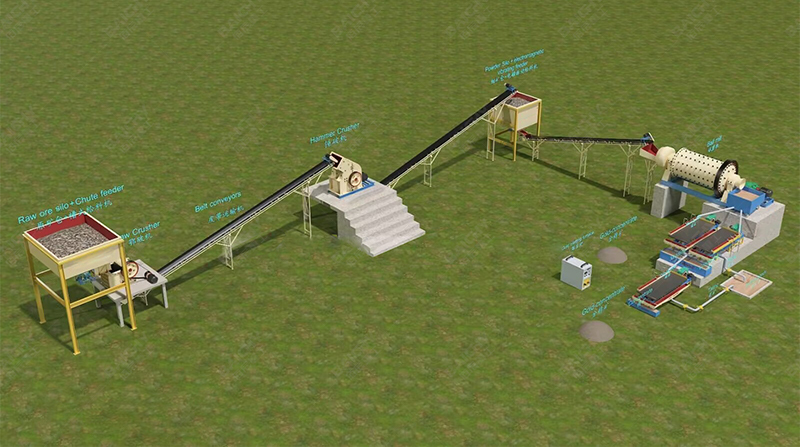

II. Core Equipment Analysis

1. Leaching Tank

• Function: Sodium cyanide solution reacts with the ore to dissolve gold elements.

• Selection Considerations: Corrosion-resistant materials (e.g., stainless steel), matching of stirring intensity and tank volume. 2. Adsorption Tower/Tank

• Function: Adsorbs gold ions onto loaded activated carbon. CIP requires multiple stages in series, while CIL can combine leaching and adsorption.

• Key Parameters: Carbon density, flow rate control, automated monitoring system.

3. Desorption Electrolysis System

• Function: Strips gold from gold-loaded carbon, producing gold mud.

• Recommended High-Efficiency Equipment: High-pressure desorption column + electrolysis cell combination, recovery rate up to 99%.

III. Equipment Selection and Maintenance Recommendations

• Scale Matching: Modular CIL equipment is preferred for daily processing capacities below 500 tons; large-scale projects can adopt segmented optimization of CIP.

• Automation Upgrade: Integrated PLC control system for real-time monitoring of cyanide concentration and carbon activity.

• Maintenance Focus: Regularly clean the adsorption tank, check agitator wear, and prevent activated carbon blockage.

The choice between CIP and CIL technologies depends on ore characteristics and production goals, while equipment performance directly determines gold recovery efficiency. Investing in cutting-edge leaching, adsorption, and desorption equipment, combined with intelligent management, will significantly improve the economic benefits of gold mining.