Gravel crusheris a kind of mechanical equipment specially used for crushing hard materials such as gravel and ore. It is designed to crush large-sized gravel particles into smaller-sized particles by applying external force to meet the needs of different fields. Here are some analyses on whether gravel crusher can maximize gravel crushing efficiency:

Crushing principle and mechanism:

Gravel crusher usually crushes gravel by extrusion, shearing, impact or grinding.

Different crushing mechanisms are suitable for different types of gravel and required crushing particle size.

Factors to improve crushing efficiency:

• Equipment type and specification: Selecting the crusher model and specification suitable for specific application requirements can ensure the best crushing effect.

• Feed quality: Reasonable feed particle size, moisture and uniformity have an important impact on crushing efficiency.

• Operation and maintenance: Correct operation method and regular equipment maintenance can ensure the stable operation and efficient work of the crusher.

• Crushing process optimization: Crushing efficiency can be further improved by optimizing the crushing process, such as adopting multi-stage crushing, screening and re-crushing steps.

Advantages of gravel crusher:

• Efficient crushing: Gravel crusher adopts advanced crushing technology and optimized crushing chamber design, which can crush gravel quickly and efficiently.

• Energy saving and environmental protection: Modern gravel crushers are usually equipped with energy-saving motors and noise reduction measures to reduce energy consumption and noise pollution.

• Easy to maintain: Many gravel crushers are designed with structures that are easy to inspect and replace wear parts, reducing maintenance costs and time.

Effects in practical applications:

In practical applications, gravel crushers can usually significantly improve the crushing efficiency of gravel, reduce production costs, and meet various particle size requirements.

However, the improvement of crushing efficiency is also affected by many factors, such as raw material properties, equipment performance, operation level, etc.

In summary, gravel crusher can indeed maximize the crushing efficiency of gravel through its advanced crushing technology and optimized design. However, to achieve the best effect, it is also necessary to comprehensively consider factors such as equipment selection, feed quality, operation and maintenance, and crushing process optimization. In practical applications, selection and adjustment should be made according to specific circumstances to achieve the best crushing effect and economic benefits.

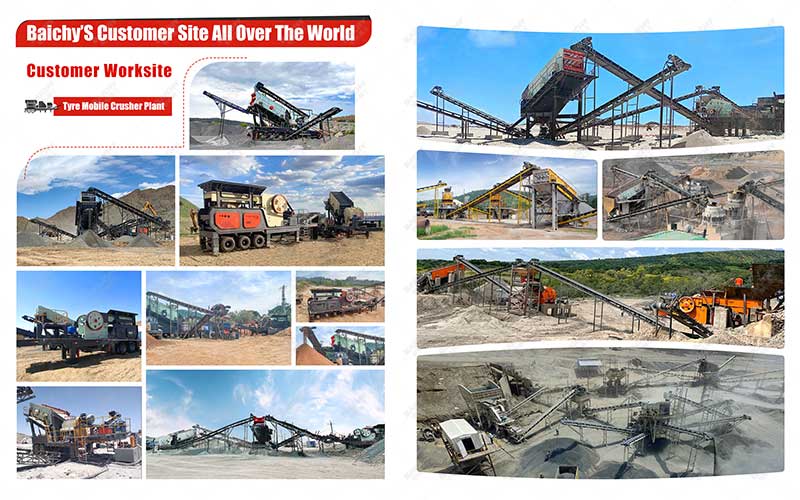

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Further reading: