As important equipment in mining, construction, and other industries, the maintenance of jaw crusher is of great significance to extend the life of equipment and improve production efficiency. The following are some key maintenance measures:

Daily inspection and maintenance of jaw crusher

1. Check the bearing temperature: For rolling bearings, the temperature should not exceed 70℃; for sliding bearings, the temperature should not exceed 60℃. If the temperature exceeds the specified temperature, stop the machine immediately for inspection and troubleshooting. At the same time, ensure that the lubrication system works normally without knocking sound, regularly observe the oil pressure gauge value, and check the oil tank oil level and lubrication system for oil leakage.

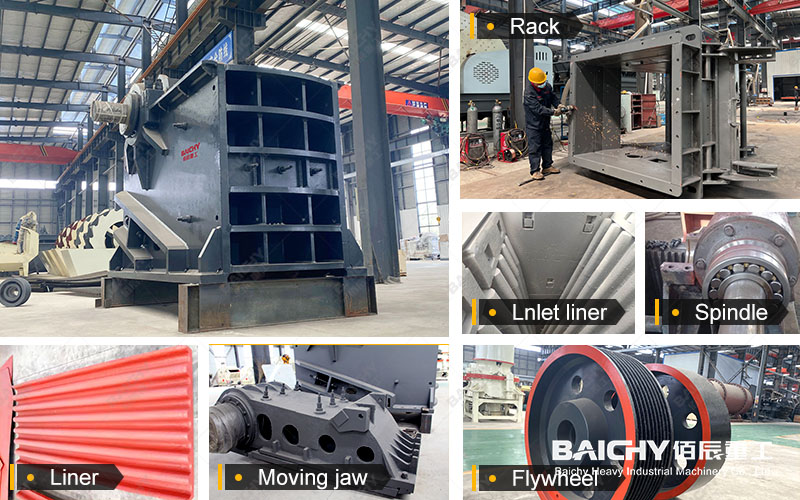

2. Tighten bolts and lubricate: Check the tool screws of the jaw crusher regularly. After the new machine is used for 1 hour, the screws of the moving and fixed knives need to be tightened with tools to strengthen the fixation between the blade and the knife holder. In addition, it is necessary to lubricate various parts regularly, such as the movable jaw suspension bearing and the elbow of the toggle plate. The small crusher should be refueled every 40-60 minutes, and the elbow of the toggle plate should be dripped with engine oil every 3-4 hours. An appropriate amount of grease should be added every 400 working hours. After 2000 working hours, the main shaft assembly needs to be opened to clean the bearings. Generally, new bearings should be replaced after 7200 working hours.

3. Check the wear condition: Regularly check the wear condition inside the machine, such as the wear degree of the cone cap, the upper and lower flow channel linings of the impeller, the circumferential guard plate, and the wear-resistant block, and replace the parts with more serious wear in time and repair these parts.

Regular maintenance and adjustment of the jaw crusher

1. Replace lubricating oil: Regularly replace the lubricating oil in the oil tank, generally once every six months, and check whether the oil contains metal powder and other dirt. If there is dirt, stop the machine and disassemble the bearings and other parts for inspection.

Adjust the tightness of the conveyor belt: Regularly adjust the tightness of the conveyor belt to ensure that the conveyor belt is evenly stressed. If the belt is found to be too worn, please replace it in time.

2. Adjust and replace the jaw plate: The worn state of the jaw plate has a significant impact on the working capacity of the crusher. It is best to check the wear state regularly to determine when to invert, interchange, and replace the jaw plate.

3. Common wear conditions and treatment measures include: when the bottom of the movable jaw plate has been worn 1/3 and the bottom of the fixed jaw plate has been worn 2/3, the two jaw plates should be inverted; when the top and bottom of the movable jaw plate are worn 1/3, the middle is worn half, and the top and bottom of the fixed jaw plate are worn 2/3, the two jaw plates should be exchanged; when the top and bottom of the two jaw plates are completely worn, they should be replaced.

Maintenance of jaw crusher foundation and feeding system

1. Foundation treatment: It is normal for the jaw crusher to vibrate strongly during operation, and the reinforced concrete structure is used to stabilize the foundation. After operation, cracks and signs of looseness should be adjusted in time to avoid adverse effects on safe operation.

2. Replace the feeder bottom plate: Long-term impact and wear with stones may cause large holes in the feeder bottom plate. When it can no longer be repaired by welding, it should be replaced in time to ensure safe production.

3. Correct feeding: In order to make the jaw plate wear evenly and reduce operating costs, the ore should be evenly distributed along the inlet of the feeder and fill the crushing chamber. At the same time, prevent iron blocks from entering the crushing chamber, avoid the ore height exceeding the fixed jaw plate, and the maximum ore size should be 75mm-100mm smaller than the jaw crusher feed opening to prevent clogging the crushing chamber and affecting the crushing efficiency.

In summary, through daily inspection and maintenance, regular maintenance and adjustment, and foundation and feeding system maintenance, the equipment life of the jaw crusher can be effectively extended and production efficiency can be improved.

Service Guarantee

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.