In complex mineral processing, accurately separating ground materials according to particle size is the first step to achieving efficient separation. The spiral classifier, as the core equipment in this process, has become an indispensable tool in many mineral processing plants due to its simple structure, reliable operation, and stable classification. This article will provide a comprehensive understanding of spiral classifiers, especially how to make an informed choice between high-weir spiral classifiers and submerged spiral classifiers based on your needs.

I. What is a Spiral Classifier? What role does it play in mineral processing?

A spiral classifier is a device that uses the principle of different settling velocities of solid particles in a liquid to perform mechanical classification. It is usually integrated with a ball mill to form a closed-loop system, primarily undertaking two tasks:

1. Particle Size Classification: Separating the ground product into qualified fine particles (overflow) and unqualified coarse particles (return sand), with the coarse particles returned to the mill for regrinding.

2. Dewatering and Desliming: Using the agitation and lifting action of the spiral, the slurry is washed, dewatered, and some fine mud is removed.

Its high efficiency and reliability make it widely used in the processing of various minerals such as iron ore, copper ore, gold ore, and quartz sand.

II. Working Principle of Spiral Classifiers: Simple Yet Efficient

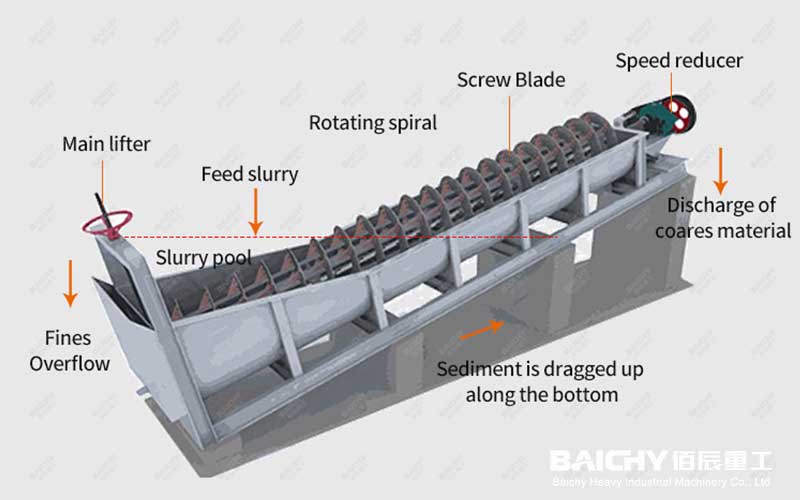

The main body of a spiral classifier is an inclined rectangular trough with a longitudinal spiral shaft installed inside. During operation, the slurry enters the settling zone from the side of the trough. Under the influence of gravity:

• Coarse, heavy particles: rapidly settle to the bottom of the trough, are captured by the rotating spiral blades, and are lifted upwards as "return sand," returning to the mill, much like a screw conveyor.

• Fine, light particles: suspended in the slurry, flow towards the overflow weir with the liquid flow, and are ultimately discharged as "overflow" product to enter the next separation process.

This process is continuous, achieving automatic and continuous material classification.

III. Core Selection: High-Weir Type vs. Submerged Spiral Classifiers

Based on the different immersion depths of the spiral end blades in the slurry, spiral classifiers are mainly pided into two types, which is also the core of the selection process.

Features: High-weir spiral classifier; Submersible spiral classifier

Structural Features: The overflow weir is higher than the spiral bearing but lower than the blades at the top of the spiral. The spiral tip is partially exposed above the liquid surface. The overflow weir is completely submerged below the slurry, and the spiral tip is completely submerged below the liquid surface in the settling zone.

Classification Zones: Smaller settling zone area; shallower water. Larger and deeper settling zone area; deeper pool.

Applicable Particle Size: Coarser, typically used for classifying particles larger than 0.15mm. Finer, typically used for classifying particles smaller than 0.15mm.

Main Applications: More suitable for processing coarser materials, often used for classification in the first stage of grinding or for dewatering and washing products. More suitable for processing fine-particle, high-viscosity slurries, obtaining finer overflow products, often used in the second stage of grinding or for classification operations requiring high fineness.

Visual Understanding: Resembles a "shallow pool," suitable for quickly separating sand. Like a "deep lake," it allows fine powders sufficient time to settle and separate.

IV. How to Choose the Right Spiral Classifier for Your Project?

Correct selection is key to ensuring production efficiency and economic benefits. Please consider the following aspects:

1. Classification Particle Size Requirements: This is the primary determining factor. Choose a high-weir type for coarser products and a submerged type for finer overflow.

2. Production Scale: Select the appropriate diameter (Φ300, Φ750, Φ1200, Φ2400, etc.) and length model based on the processing capacity.

3. Ore Properties: Consider the ore's density, mud content, viscosity, etc. Submerged types are more effective for classifying fine, sticky materials.

4. Process Configuration: Is it paired with a single-stage mill or a two-stage mill? This directly relates to the required classification particle size.

Whether it's the high-weir spiral classifier requiring efficient dewatering and coarse particle classification, or the submerged spiral classifier pursuing fine separation, both are mature and crucial pieces of equipment in modern mineral processing technology. Understanding their principles and differences is fundamental to optimizing the entire mineral processing flow and improving mineral processing efficiency.