In the increasingly competitive building materials industry, constructing a high-efficiency, low-cost limestone crushing plant is key to market success. Traditional stationary production lines require massive infrastructure, have rigid equipment layouts, and incur high transportation costs, making them unsuitable for the flexibility and efficiency demands of modern mines. The emergence of tracked mobile crushing plants, with their revolutionary mobile crushing mode, is becoming the ideal solution for high-efficiency limestone crushing plants.

I. Why are tracked crushers the best partner for limestone crushing?

Limestone typically has medium to low hardness and is easily crushed, making it an ideal raw material for building stone. Tracked mobile crushers perfectly meet many of the needs of limestone mining:

• High mobility and direct access to the mining face: Utilizing a tracked chassis, the equipment can be driven directly to the mine face, achieving crushing wherever the raw material is, completely eliminating the huge costs of transporting raw materials by truck.

• Integrated design, rapid commissioning: The equipment integrates a vibrating feeder, crusher, and screening system, and comes with its own diesel generator or external power supply. Upon arrival, no complex infrastructure construction is required to quickly set up a production line, significantly shortening the project cycle.

• Cost reduction and efficiency improvement from the source: By directly performing coarse and medium crushing in the mining area, large pieces of limestone are crushed into smaller particles, which are then transported to the next process via belt conveyors. This significantly reduces vehicle transportation and fuel consumption, directly improving economic efficiency.

II. Typical Workflow of Tracked Mobile Crusher in a Limestone Crushing Plant

An efficient tracked solution typically consists of the following units working in tandem:

1. Feeding and coarse crushing unit (tracked jaw crusher mobile station): As the primary crusher, the powerful jaw crusher performs primary crushing on the blasted large pieces of limestone (up to 1000mm or more), producing uniform primary aggregate.

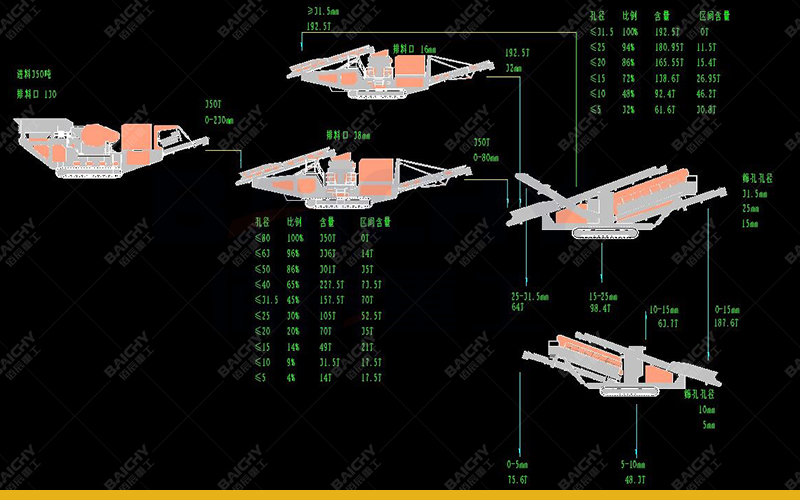

2. Medium crushing and screening unit (tracked impact crusher/cone crusher mobile station): The primary aggregate is transported to the medium crushing unit via belt conveyor. For limestone, impact crushers are commonly chosen due to their large crushing ratio and good particle shape, producing high-quality crushed stone aggregate. This unit typically forms a closed-loop circulation with a vibrating screen to ensure precise and controllable finished product particle size.

This two-stage, closed-loopp mobile crushing combination can be flexibly adjusted to produce high-quality limestone aggregate in various sizes (e.g., 0-5mm, 5-10mm, 10-20mm, etc.) to meet different customer needs.

III. Choosing a tracked crusher brings four core values to your crushing plant:

1. Maximized economic benefits: Saves significant investment in infrastructure and plant buildings, and fundamentally reduces ore transportation costs, significantly lowering the production cost per ton of stone.

2. Significantly improved production efficiency: Quick equipment changeover reduces downtime, enabling continuous and efficient production, particularly suitable for large mines developing multiple mining sites simultaneously.

3. Green and environmentally friendly, in line with national policies: Reduces vehicle exhaust emissions and noise pollution in the mining area, and easily meets green mine construction standards by equipping it with dust removal and noise reduction equipment.

4. High adaptability and low investment risk: For projects with uncertain mining periods or scattered mining areas, tracked mobile crushing equipment can be moved, relocated, or leased at any time, avoiding the risk of asset sinking associated with fixed production lines.

In today's pursuit of high efficiency, energy saving, and environmental protection, tracked mobile crushers are no longer merely a supplement to traditional fixed production lines, but rather the core choice for building modern, high-efficiency limestone crushing plants. It is not just a machine, but a complete and advanced production and operation concept.

If you are planning or upgrading your limestone crushing project and hope to achieve a breakthrough in cost reduction and efficiency improvement, please feel free to contact us. Our technical experts will provide you with the optimal tracked mobile crushing plant configuration and quotation based on your specific working conditions and output requirements.