In the field of gold beneficiation, cyanide leaching remains one of the main methods for processing fine-grained disseminated gold ores due to its high recovery rate and relatively mature technology. A well-designed small-scale gold cyanide leaching production line often begins with efficient crushing and grinding processes. Today, we will delve into how jaw crushers and ball mills play key roles in this process and achieve synergistic effects.

I. Introduction to Cyanide Leaching Process: Why is Fine Raw Material Preparation Necessary?

The basic principle of gold extraction via cyanide leaching is to use a dilute sodium cyanide (or potassium cyanide) solution to dissolve gold and silver in the ore under aerobic conditions, generating soluble gold cyanide complexes, which are then recovered through displacement or adsorption.

The key prerequisite for the success of this process is achieving sufficient dissociation and exposure.

• Dissociation: Releasing gold particles from the gangue minerals that encapsulate them.

• Exposure: Fully exposing the surface of the gold particles to contact the cyanide solution.

If the ore is not crushed and ground finely enough, gold particles will remain encapsulated, preventing the cyanide solution from reacting with them and significantly reducing the recovery rate. Therefore, crushing and grinding are the pioneers of the entire process, and their effectiveness directly determines the success or failure of subsequent leaching.

II. Core Equipment of the Production Line: The Collaborative Process of a Golden Partner

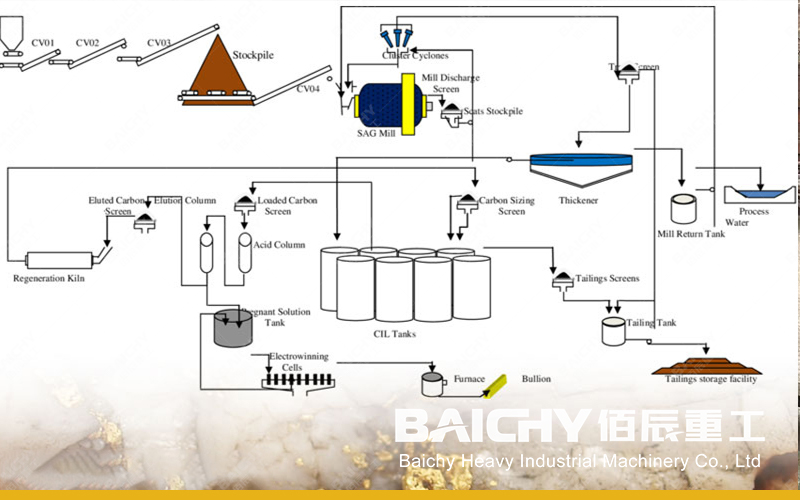

A typical small-scale cyanide leaching production line typically follows a classic two-stage, closed-circuit process for its front-end crushing and grinding section. The core equipment is the jaw crusher and the ball mill.

1. Coarse Crushing Expert: Jaw Crusher

Jaw crushers are renowned for their robust structure, high processing capacity, and ease of maintenance, making them the king of mine crushing.

• Role: Primary crushing (coarse crushing). Responsible for crushing large chunks of raw ore (up to several hundred millimeters in size) after blasting to a medium size (usually below 100-200 millimeters).

• Working Principle: Through the periodic squeezing motion between the moving jaw plate and the fixed jaw plate, the ore is crushed like a tiger's mouth.

• Advantages in Cyanide Lines:

◦ High Crushing Ratio: Large feed size and uniform output particle size reduce the burden on subsequent medium and fine crushing.

◦ Robust and Durable: Even with small amounts of clay or other impurities in the ore, it is not prone to clogging and operates stably.

◦ Low Investment Cost: Relatively low equipment and maintenance costs, making it ideal for small production lines with limited budgets.

2. Fine Grinding Expert: Ball Mill

After coarse crushing by jaw crushers and medium crushing (often completed by cone crushers or fine jaw crushers), the ore enters the ball mill, completing the transformation from crushed stone to mineral powder.

• Role: Grinding operation. Grinds crushed ore with a particle size of approximately 10-25mm to the particle size required for cyanide leaching (typically -200 mesh, accounting for 85%-95%).

• Working Principle: The cylinder contains steel balls (grinding media). As the cylinder rotates, the steel balls are lifted to a certain height and then thrown down, grinding the ore into fine powder through impact and abrasion.

• Key Role in the Cyanide Line:

◦ Achieving Inpidual Liberation: Thorough grinding is the only way to ensure the liberation of gold particles from the gangue.

◦ Controlling Final Particle Size: Grinding fineness is one of the most important process parameters in cyanide leaching. Ball mills can precisely control this by adjusting the feed rate, steel ball ratio, and concentration.

◦ Creating Optimal Conditions for Leaching: The slurry after grinding is directly adjusted before entering the leaching tank, ensuring a smooth process flow.

III. 1+1>2: Synergistic Effect of Jaw Crusher and Ball Mill

The combination of these two devices is not a simple series connection, but a deep synergy:

1. Each performs its specific function, maximizing efficiency: The jaw crusher handles the powerful work, completing the large-scale crushing with minimal energy consumption; the ball mill focuses on the fine work, using energy for effective grinding rather than unnecessary impact. This pision of labor significantly reduces the overall system's energy consumption.

2. Creating optimal operating conditions for each other: The jaw crusher ensures that the material fed into the ball mill has a uniform and appropriate particle size. If the feed particle size is too large, the ball mill efficiency will drop sharply; if the particle size is too fine (such as from a high-pressure roller mill), it may affect the grinding effect of the steel balls. The appropriate particle size provided by the jaw crusher is the foundation for the efficient operation of the ball mill.

3. Ensuring stable operation of the production line: The stability of the jaw crusher provides a continuous and stable supply of raw materials for all subsequent processes, avoiding uneven feeding of the ball mill, thereby ensuring the stability of the chemical reaction in the leaching tank and the final recovery rate.

IV. Important Considerations for Building a Small-Scale Production Line

If you are planning to invest in a small-scale gold cyanide leaching production line, in addition to selecting reliable equipment, you should also pay attention to the following:

• Ore properties are fundamental: Before conducting process design, a detailed mineralogical analysis of the raw ore (gold occurrence state, embedded particle size, hardness, clay content, etc.) is essential. This is the only basis for determining the crushing and grinding process and equipment selection.

• Automation and Control: A simple PLC automatic control system on a small production line can monitor the jaw crusher's feed and the ball mill's concentration and fineness, significantly improving efficiency, stabilizing performance, and reducing labor costs.

• Environmental Protection and Safety: The cyanidation process demands extremely high environmental and safety standards. Equipment layout must consider leakage prevention, wastewater collection and treatment, and strict operating procedures must be established.

In a small-scale gold cyanide leaching production line, the jaw crusher and ball mill, this core duo, are the cornerstones for realizing the dream of gold extraction. One crushes, the other grinds; one is rigid, the other flexible, together providing the perfect stage for cyanide leaching. Wise equipment selection, reasonable process design, and a deep understanding of synergies will be key steps to your project's success and maximizing economic benefits.