100 t/h Copper Ore Hammer Crusher Manufacturer

In the field of non-ferrous metal mining and beneficiation, the efficiency and economics of copper processing have always been a core focus of the industry. As a key primary crushing equipment, a hammer crusher with a processing capacity of 100 tons/hour directly determines the smoothness of the subsequent production line and the quality of the finished product. With the development of copper ore resources towards lower grades and complex embedded structures, more stringent requirements are placed on the processing capacity, wear resistance, and stability of crushing equipment.

Our company, with 20 years of experience in manufacturing mining crushing equipment, has a deep understanding of the pain points in the copper ore crushing process. The 100-ton/hour hammer crusher is not just a capacity figure, but a complete system solution. It needs to be adapted to the characteristics of copper ore (such as medium hardness and common associated minerals) to ensure efficient crushing while controlling over-crushing, creating ideal conditions for subsequent operations such as flotation.

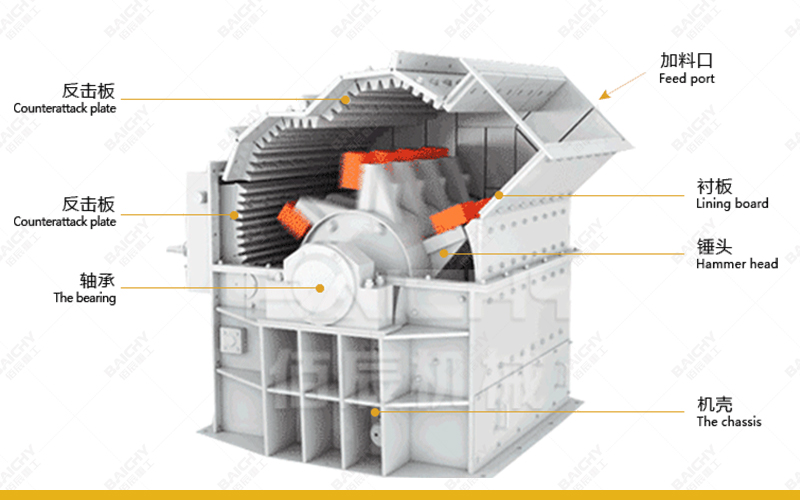

PC Hammer Crusher Customer Structure Diagram

Core Equipment Advantages

1. High Efficiency and High Output, Stable Performance: Optimized rotor design and crushing chamber shape ensure a stable output of 100 tons per hour, meeting the needs of continuous operation.

2. Strong Wear Resistance and Long Service Life: Key hammer heads and liners are made of high-chromium alloy composite materials or special wear-resistant steel. Targeting the abrasive components that may be present in copper ore, this significantly extends the service life of wear parts and reduces tonnage costs.

3. Controllable Discharge Particle Size and Excellent Particle Shape: By adjusting the grate gap, the discharge particle size can be flexibly controlled, producing ideal products with uniform particles and minimal fines, improving the copper concentrate recovery rate.

4. Robust Structure and Easy Maintenance: The overall heavy-duty frame design results in low operating vibration. The maintenance door is designed for user-friendliness, and the hammer heads can be symmetrically interchanged, shortening maintenance downtime.

5. Intelligent Adaptation and Economical Operation: It can be matched with variable frequency speed control, adjusting power consumption according to the incoming material, achieving high efficiency and energy saving.

Actual Application Case

In a large-scale copper mining and beneficiation project in my country, the original primary crushing equipment suffered from unstable capacity and rapid wear. Our company customized a PCZ-1620 heavy-duty hammer crusher for them, with a processing capacity precisely matching 100-110 tons of copper ore per hour. After the equipment was put into operation, it not only stably achieved the production capacity target, but also, due to its excellent wear resistance, the service life of the hammer heads increased by more than 40% compared to the original equipment. At the same time, the uniform crushed product created better conditions for the subsequent ball mill, improving the overall energy efficiency of the processing plant by approximately 15%, and receiving high recognition from the customer.

Recommended Related Equipment

For a complete copper ore crushing production line, in addition to the core 100 tons/hour hammer crusher, we also recommend considering:

Feeding equipment: Heavy-duty plate feeder to ensure uniform and continuous feeding.

Secondary and fine crushing equipment: Cone crusher or fine crushing hammer crusher for secondary crushing to obtain finer particle size for grinding.

Screening equipment: Circular vibrating screen to form a closed-loop system and optimize the final product grading.

Conveying and dust removal system: Belt conveyor and pulse bag dust collector to ensure clean and efficient production.

Frequently Asked Questions (FAQ)

Q1: Is a 100 tons/hour processing capacity suitable for our small and medium-sized copper mine?

A: This capacity is a common configuration for medium to large-scale processing plants. We can perform precise calculations and recommend suitable models based on your actual ore volume and operating schedule (such as 8 hours or 24 hours of continuous operation) to ensure the best return on investment.

Q2: Does the equipment have requirements for the moisture content of the copper ore?

A: Standard hammer crushers generally require a material moisture content of less than 15%. If your ore has high viscosity or humidity, we can provide anti-clogging solutions such as adjusting the grate gap and cavity heating, or recommend a more suitable box-type crusher.

Q3: What is the replacement cycle for key components (such as hammer heads)?

A: This depends on the abrasiveness of the ore (such as SiO2 content). Under medium abrasive copper ore conditions, the specially designed hammer heads we provide can usually process tens of thousands of tons of ore. We provide detailed wear part monitoring and replacement guidance services.

Q4: Can you provide overall production line design and installation support?

A: Absolutely. Based on 20 years of experience, we can not only provide inpidual machines but also offer our customers comprehensive technical support and turnkey engineering services, from process layout and equipment selection to installation guidance and commissioning.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.