Impact Crushers and Impactors for Mineral Crushing

In the field of mining crushing, impact crushers and impactors have become core equipment in mineral processing due to their high efficiency and energy-saving crushing principles. As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing comprehensive solutions for the global mining industry, helping customers improve production efficiency and reduce operating costs.

This article will delve into the advantages, application scenarios, and practical cases of impact crushers and impactors, analyzing their key role in mineral crushing.

| Key Words | Limestone Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

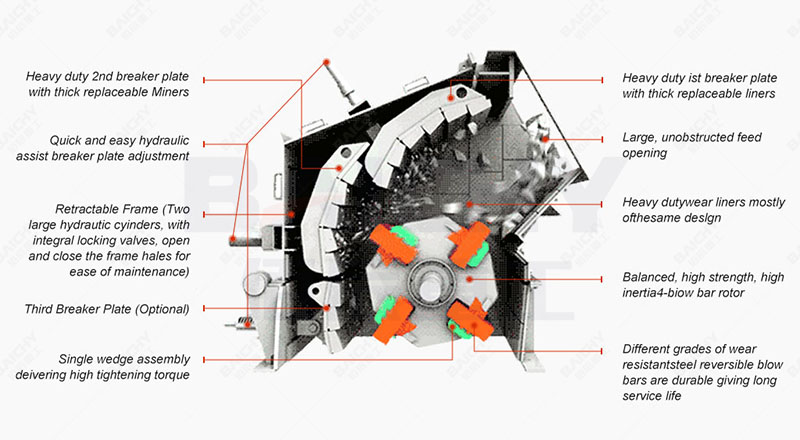

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Product Advantages

1. High-efficiency crushing capacity: Impact crushers use a high-speed rotating rotor to accelerate and crush mineral materials, achieving a high crushing ratio and fine particle shape, especially suitable for medium-hard materials.

2. Energy saving and environmental protection: Optimized equipment structure reduces energy consumption by 20%-30% compared to traditional crushers. Equipped with a dust removal system, it reduces dust pollution and meets green mining standards.

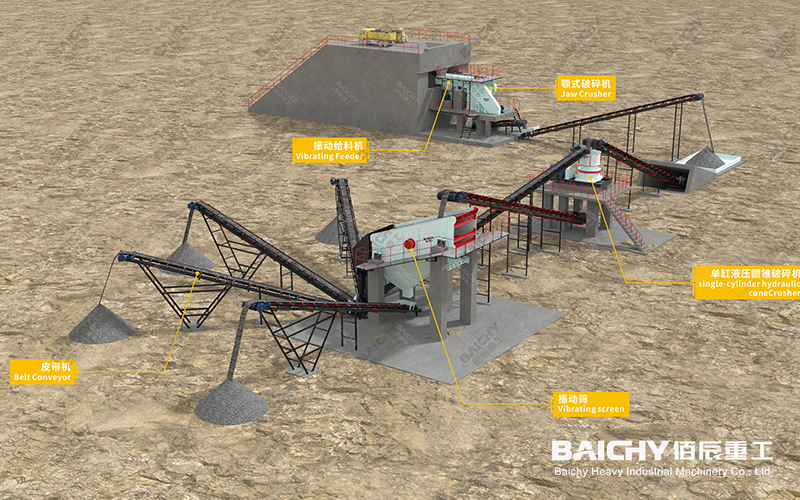

3. High flexibility and adaptability: Impactors can be integrated into mobile or fixed crushing lines, easily handling different mineral hardness, moisture content, and output requirements, suitable for perse mining environments.

4. Low Maintenance Costs: Key components are made of wear-resistant materials, extending their lifespan. The modular design simplifies maintenance processes, reduces downtime, and improves overall operational efficiency.

5. Intelligent Control: Optional automation systems monitor equipment operation status in real time, enabling remote control and fault warnings, optimizing production management.

PF Impact Crusher Structure Diagram

Application Scenarios: Impact crushers and impactors are widely used in the following fields:

• Metal Mines: Used for primary and secondary crushing of metallic minerals such as iron ore, copper ore, and gold ore, improving mineral processing recovery rates.

• Construction Aggregate Production: Crushing limestone, granite, etc., to produce high-quality sand and gravel aggregates to meet infrastructure needs.

• Industrial Mineral Processing: Applied to the fine crushing of non-metallic minerals such as coal, gypsum, and phosphate rock, increasing product added value.

• Recycling: Crushing construction waste, metallurgical slag, and other renewable resources, promoting a circular economy. Its flexible configuration can adapt to fixed production lines or mobile crushing stations, meeting the needs of all scenarios from large mines to small quarries.

Project Cases

• Australian Iron Ore Project: We provided multiple impact crushers for a large mining company for secondary crushing of iron ore. The equipment has a daily processing capacity of 5,000 tons, producing uniformly shaped crushed material, helping the client improve subsequent grinding efficiency by 20% and saving approximately US$150,000 in energy costs annually.

• Southeast Asian Limestone Quarry: The client used our mobile impact crushing station, flexibly relocating it to multiple mining sites. In the two years since the project started operating, output has remained stable at 300 tons/hour, and maintenance frequency has been reduced by 30% compared to traditional equipment, significantly improving operational efficiency.

• African Gold Mine Expansion Project: We customized an impactor system, integrating it into the existing crushing line to process high-hardness gold ore. The lifespan of wear-resistant components was extended by 40%, supporting a 25% increase in project capacity, and receiving high praise from the client.

Aggregate crushing plant

FAQ

1. What mineral hardness is the impact crusher suitable for?

Suitable for medium-hard and lower hardness materials (e.g., Mohs hardness ≤ 7), such as limestone, coal, and iron ore. For ultra-hard materials, it is recommended to use other crushing equipment.

2. What is the equipment maintenance cycle?

Routine maintenance is performed every 500 hours. Wear-resistant parts are replaced every 6-12 months (depending on material abrasion). We provide full lifecycle technical support.

3. Can mobile solutions be customized?

Yes, we offer customized tracked or wheeled mobile crushing plants for rapid deployment, suitable for short-term or dispersed projects.

4. How is the energy saving effect quantified?

Based on project data, energy consumption is reduced by 20%-30% compared to jaw crushers, depending on material characteristics. We can provide an energy consumption assessment report.

5. What is the global service support like?

We have service centers in Asia, Africa, and the Americas, providing installation training, spare parts supply, and remote diagnostics to ensure stable equipment operation.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.