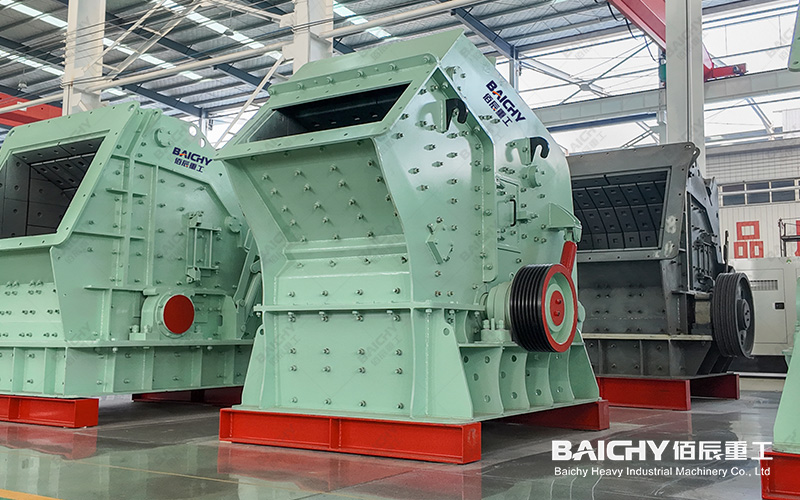

Impact Crusher & Mill Manufacturer | Comprehensive Mining Crushing Solutions

In the mining and mineral processing industry, the selection of crushing equipment directly impacts production efficiency and cost control. As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing global mining customers with comprehensive, high-performance crushing solutions. This article will provide an in-depth introduction to the working principles, unique advantages, application scenarios, and practical cases of impact crushers and impact mills to help you better select the right equipment.

| Key Words | Impact Crusher & Mill Manufacturer |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

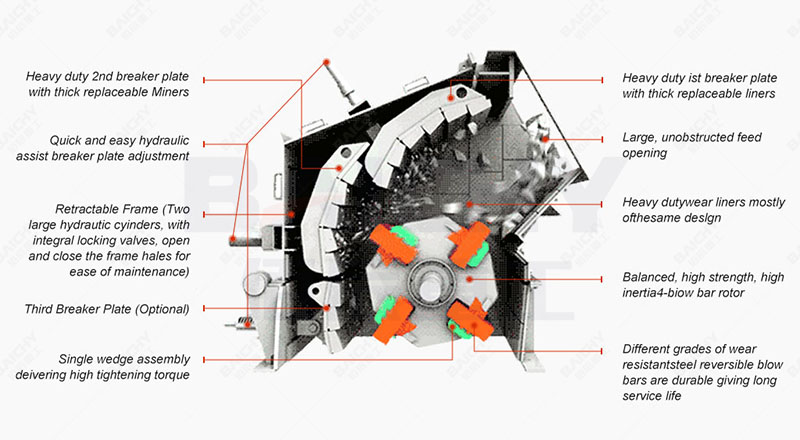

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Product Overview

Impact crushers and impact mills are high-efficiency crushing equipment that utilize the stone-on-stone or stone-on-iron principle. Material is thrown onto impact plates by a high-speed rotating rotor, achieving impact crushing. Both perform exceptionally well in fine crushing and sand making, especially suitable for processing medium to high hardness materials.

Product Advantages

1. High Efficiency and Energy Saving: Optimized crushing chamber design improves impact efficiency, reducing energy consumption by approximately 20%-30%.

2. Excellent Finished Product Particle Shape: Produces three-dimensional, uniform particles with low needle-like and flaky content, suitable for high-standard aggregate requirements.

3. Easy Maintenance: Hydraulic opening design; core components made of wear-resistant materials, extending lifespan by over 50%.

4. Environmentally Friendly and Low-Noise: Enclosed structure combined with dust removal technology; operating noise below 75dB, meeting green mining requirements.

5. Intelligent Control: Can be integrated with automated systems, real-time monitoring of operating status, and remote adjustment.

PF Impact Crusher Structure Diagram

Application Scenarios

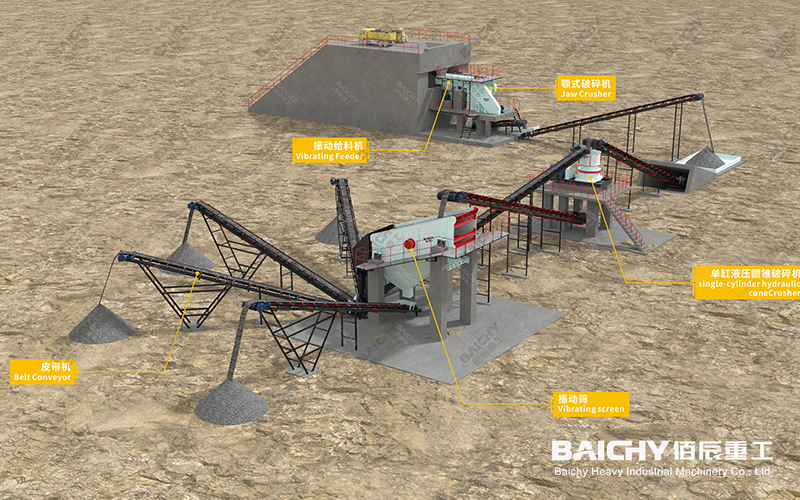

• Sand and Gravel Aggregate Production: Provides high-quality manufactured sand for construction, highways, and railways.

• Fine Crushing in Metal Mines: Suitable for medium and fine crushing processes in iron ore, copper ore, gold ore, etc.

• Industrial Grinding: Impact mills can be used for grinding materials such as limestone and dolomite.

• Building Material Recycling: Crushing and regenerating construction waste to achieve resource recycling.

• Cement Production: Raw meal preparation and clinker pre-crushing, improving production line energy efficiency.

Aggregate crushing plant

Project Cases

Case 1: Australian Iron Ore Project

The client needed to process 500 tons of magnetite per hour, requiring a finished product particle size of <5mm. We configured two heavy-duty impact crushers, achieving a 40% increase in production capacity and a wear-resistant parts lifespan of 3000 hours, helping the customer save over $200,000 in annual maintenance costs.

Case Study 2: Vietnam Expressway Aggregate Project

To meet the high-standard concrete aggregate requirements, we provided an impact crusher + shaping machine combined system. The finished product particle sphericity reached 0.9 or higher. The project has been operating stably since its commissioning and has received multiple repeat purchases from the customer.

Frequently Asked Questions (FAQ)

Q1: How to choose between an impact crusher and a cone crusher?

A: Impact crushers are suitable for medium to low hardness materials, resulting in better finished particle shape; cone crushers are suitable for high hardness materials, offering stronger wear resistance. The choice can be made based on material characteristics and product requirements.

Q2: Is the equipment suitable for damp materials?

A: For high-humidity materials, we can provide a heated feeding system or cavity modification solutions to prevent clogging.

Q3: What is the lifespan of key components?

A: Using composite ceramic/high-chromium alloy wear-resistant parts, the rotor lifespan is ≥6000 hours and the impact block lifespan is ≥1500 hours under normal operating conditions.

Q4: Do you provide EPC turnkey services?

A: We support full-process services from design and installation to training, and have delivered 200+ EPC projects globally.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.