In the field of mining crushing, choosing the right crushing equipment is crucial to determining the efficiency of a production line. Jaw crushers are used for primary crushing, and cone crushers for medium and fine crushing—this is an industry consensus.

However, when dealing with materials of medium to low hardness, and pursuing excellent particle shape and higher efficiency, the impact crusher is undoubtedly the brightest star. It is not just a machine, but a "shaping master" based on the principle of high-efficiency kinetic energy.

Today, we will delve into the working principle of this "kinetic energy hammer" for mine owners and industry peers, to see how it becomes your secret weapon to enhance market competitiveness.

Part One: The Source of Power—The Core Principle of Impact Crushing

The working principle of an impact crusher can be figuratively understood as "stone striking stone" or the "anvil effect." Unlike jaw crushers and cone crushers, which rely on static pressure forces such as "compression and bending," the core of the impact crusher is high-speed impact and the instantaneous release of kinetic energy.

Its workflow can be summarized in the following key steps:

1. Acceleration: Creating a High-Speed "Bullet"

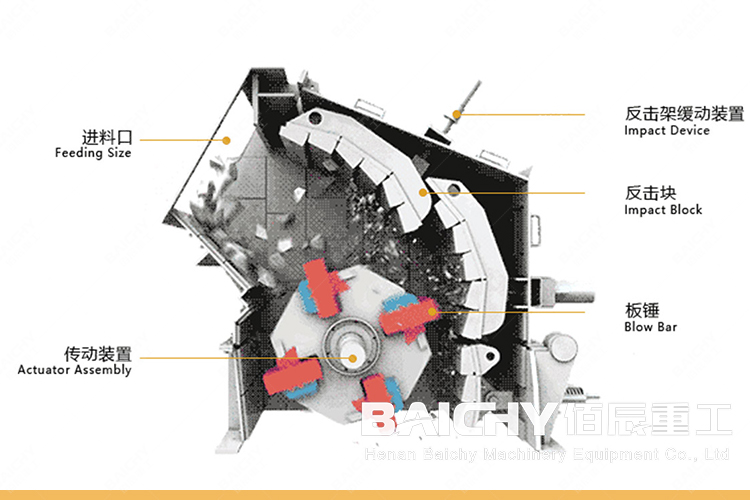

Materials enter the top of the crusher through the feed inlet and fall onto the high-speed rotating rotor. The rotor is equipped with sturdy hammers, and driven by a motor, it reaches extremely high linear speeds (60-80 meters per second or even higher). The material entering the rotor is violently accelerated by the hammers, gaining enormous kinetic energy and being propelled out like a bullet.

2. Impact: Instantaneous Release of Kinetic Energy

The accelerated material blocks, at extremely high speed, impact the impact plates fixed to the machine's perimeter guard plate, or collide violently with other freely falling material blocks inside the machine. In this instant, the enormous kinetic energy carried by the material is released, generating a huge impact force that causes the material to break along its natural texture and cleavage surfaces.

3. Friction and Grinding: Secondary Shaping

After the initial impact crushing, smaller fragments continue to collide and rub against each other within the crushing chamber. During this process, sharp edges are further smoothed, resulting in final particles that are closer to cubic in shape, with a significant reduction in needle-like and flaky content.

4. Grading and Discharge: Precise Control of Finished Product Particle Size

The crushed material is discharged through the gap between the rotor and the impact plate (discharge port). By adjusting the size of this gap, the maximum particle size of the finished product can be effectively controlled. Furthermore, modern impact crushers often have grinding chambers and screens inside, ensuring that only material meeting the particle size requirements is discharged, achieving better particle control.

Part Two: Why Choose an Impact Crusher? Analyzing its Four Irreplaceable Core Advantages

Understanding its working principle allows us to clearly see its practical benefits:

1. Superior Particle Shape Quality: Due to impact crushing, the material breaks along its weakest surfaces, producing particles that are mostly cubic in shape with a strong three-dimensional effect. This particle shape is crucial for high-standard commercial concrete mixing plants, asphalt aggregates, and construction sand, greatly improving the strength and workability of concrete and asphalt.

2. High crushing ratio and production efficiency: The crushing ratio (feed size to output size) of impact crushers can typically reach 40:1 or even higher. This means that a single unit can complete medium and fine crushing operations, simplifying the process and reducing equipment investment costs.

3. Flexible particle size adjustment: By simply adjusting the rotor speed or the impact plate gap, the output particle size can be changed within a wide range to meet different market demands, making operation very flexible and convenient.

4. Multi-purpose and highly adaptable: Especially suitable for crushing medium to low hardness materials, such as limestone, cement clinker, coal, and quartz. In the sand making industry, the vertical shaft impact crusher (VSI) is recognized as the preferred equipment for producing high-quality manufactured sand.

Part Three: Marketing Perspective: How to Convey the Value of Impact Crusher to Customers?

As marketing experts, we should not only focus on technical parameters. When presenting to clients, focus on Return on Investment (ROI):

• For owners: Emphasize the premium pricing power of high-quality aggregates with "multiple cubic meters per grain"—selling each ton of sand and gravel for an extra 5-10 yuan, resulting in significant long-term benefits.

• For contractors: Emphasize the shortened project cycle and reduced overall costs brought about by "high efficiency and flexibility."

• Always link value: Directly connect "cubic aggregate shape" with "higher-grade concrete, better road surfaces, and more robust buildings," allowing clients to see the end-market value behind the equipment's performance.

Impact crushers, with their unique working principle, play an irreplaceable role in mining crushing production lines. They are not only a technological marvel but also a strategic choice for achieving cost reduction, efficiency improvement, enhanced product value, and winning in the high-end market. As a seasoned mining equipment supplier, we not only provide stable and efficient impact crushers but also aspire to be your production process consultant, jointly planning the most competitive crushing solutions.