For customers from Thailand, first of all, we must understand the needs of customers, the raw material is limestone, and the maximum feed size is 250 mm.

1. Output: 10T/H

2. Crushing limestone needs to be screened into three sizes, 0-3mm, 4-8mm and 9-12mm

3. Equipment: jaw crusher, hammer crusher, vibrating screen, hopper, belt conveyor, and electric control cabinet.

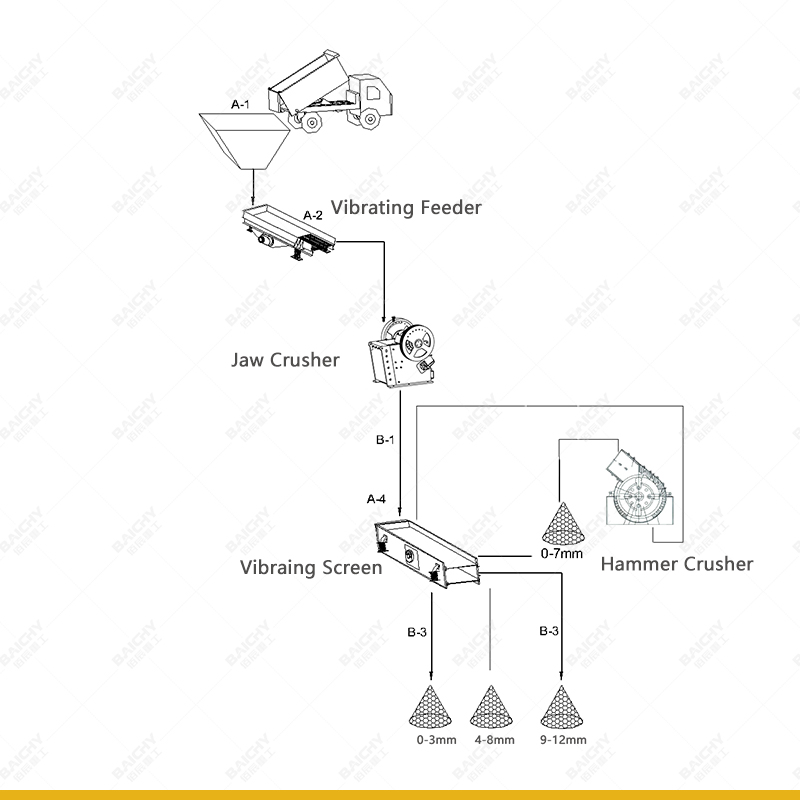

Baichy Machinery designed a solution for a 10t/h limestone crushing plant.

1. Primary crushing: limestone is fed into the vibrating feeder from the hopper, and then fed into the jaw crusher by the vibrating feeder. The jaw crusher performs preliminary crushing of the limestone;

2. Secondary crusher: the crushed aggregate is fed into the hammer crusher through the belt conveyor for secondary crushing, and the limestone crushing process is completed.

3. Screening: The next step is to screen the material after secondary crushing, which also requires an inclined conveyor, and then use a double-layer vibrating screen to screen out the three required particle sizes.

Jaw crusher, also known as jaw crusher, is a commonly used crushing equipment in industries such as mining, building materials, highways, railways, water conservancy, and the chemical industry. It mainly crushes materials through the periodic reciprocating motion of the movable jaw and the fixed jaw and has the advantages of simple structure, reliable operation, and convenient maintenance.

| Model |

Feed port size (mm) |

Feed size (mm) |

Capacity(t/h) |

Motor(kw) |

| pex250x1000 |

250x1000 |

≤210 |

10-40 |

37 |

| pe400x600 |

400x600 |

≤350 |

15-60 |

30 |

For limestone with a maximum feed size of 250mm, a variety of jaw crusher models can be selected for crushing. When selecting equipment, factors such as equipment parameters, material characteristics, and production scale should be considered comprehensively, and professional manufacturers should be consulted for more accurate selection suggestions.

Hammer crusher, also known as a hammer crusher, is a type of crushing equipment. Its working principle is mainly to use a high-speed rotating hammer to impact and crush the material.

Used to process various hard rocks and ores, such as granite, limestone, coal, iron ore, etc. These devices can effectively crush hard rocks into the required particle size for subsequent processing or extraction of metal minerals.

The hammer crusher impacts and crushes the material through the high-speed rotating hammerhead. It has high crushing efficiency and can quickly crush the material into the required particle size.

The

vibrating screen is mainly composed of a vibration motor, screen box, screen mesh, shock-absorbing spring, and other components. The vibration motor is the key component to drive the vibration of the screen box, and the screen box carries the screen mesh and the material. The screen mesh is used to separate materials of different particle sizes, and the shock-absorbing spring is used to reduce the impact of vibration on the equipment.

The belt conveyor, also known as the belt conveyor, is a continuous conveying machine that uses a flexible conveyor belt as a material-carrying and traction component. It consists of main components such as a frame, a conveyor belt, rollers, drums, tensioning devices, and transmission devices. Some heavy or long conveyors may also be equipped with auxiliary components such as sweepers, anti-deviation devices, feeding devices, unloading devices, brakes, and check valves.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.