PC600x400 Hammer Crusher | Maximum Feed Size 150mm

In the mining, building materials, and metallurgical industries, the efficiency and effectiveness of primary crushing directly impact the capacity and quality of the entire production line. Choosing a reliable primary crushing equipment is fundamental to project success. Today, we will focus on a durable and classic model – the PC600x400 hammer crusher, and invite an expert with 20 years of experience in mining crushing equipment manufacturing to provide a comprehensive analysis.

The PC600x400 is not just a model number, but also represents the core specifications of the equipment: the rotor diameter is approximately 600mm, and the rotor working length is 400mm. Its specified maximum feed size of 150mm clearly defines its processing capacity. This means it can easily handle medium-hard materials with a compressive strength not exceeding 200MPa, such as limestone, gypsum, coal, and shale, making it an ideal primary or secondary crushing equipment in medium-sized crushing production lines.

For a manufacturer with twenty years of industry experience, this specification is no accident. It balances equipment investment costs, processing capacity, energy consumption, and output particle size (usually adjustable to below 25-35mm), making it one of the golden ratio models designed to meet mainstream market demands.

PC impact crusher customer structure diagram

Equipment Overview: A Robust and Durable Crushing Core

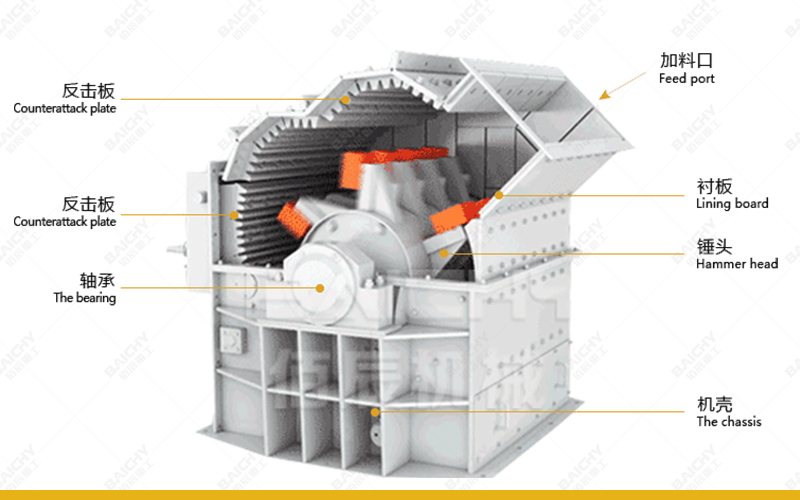

The PC600x400 hammer crusher belongs to the ring hammer crusher type, utilizing high-speed rotating hammers to impact the material, causing it to break along natural fissures, bedding planes, and joint surfaces. Its main structure includes the frame, rotor, hammers, impact plate, and screen plate.

- Processing Capacity: Approximately 12-30 tons/hour (depending on material properties and output particle size).

- Motor Power: Usually equipped with a 37-45kW motor, providing ample power.

- Key Features: Compact structure, simple operation and maintenance, large crushing ratio (generally up to 10-25), and good finished particle shape. Core Advantages: The Culmination of 20 Years of Manufacturing Experience

Our twenty years of technological expertise have endowed this equipment with superior performance that surpasses ordinary models:

1. Excellent Wear Resistance and Long Lifespan: The hammer heads are forged/cast from high-manganese steel or alloy steel and undergo special heat treatment, resulting in extremely strong impact and wear resistance. The optimized rotor dynamic balance design ensures smooth operation and significantly extends bearing life.

2. High-Efficiency and Energy-Saving Design: The reasonable crushing chamber design allows materials to be effectively impacted and rebounded within the chamber, resulting in a high single-pass crushing success rate and reducing wasted energy and consumption. Precise speed matching ensures crushing force while controlling power consumption.

3. Excellent Finished Product Particle Size Control: By adjusting the gap of the bottom sieve plate, the output particle size can be flexibly controlled to meet the feeding requirements of the next process. The product particle size is uniform, and over-crushing is minimized.

4. Strong Adaptability to Working Conditions: Designed for maximum 150mm feed size, the feed opening is reasonably designed to effectively prevent material clogging. Even with slightly higher material moisture content, its impact crushing principle allows it to work effectively, offering better anti-clogging capabilities than jaw crushers.

5. Convenient Maintenance: The machine casing adopts a hydraulic or bolt-opening design, making it very convenient to replace wear parts such as hammer heads and sieve plates, greatly reducing downtime for maintenance.

PC Hammer Crusher Customer Site Photos

Application Case: Reliability Verified in Practice

In the limestone pre-crushing workshop of a large cement plant, a PC600x400 hammer crusher was used for primary crushing of raw materials (particle size approximately 0-300mm) from the mine. The requirement was to crush the material to less than 80mm for subsequent use in a vertical mill.

- Challenge: The material occasionally had a high clay content and was somewhat sticky.

- Solution: Our engineers suggested appropriately reducing the sieve plate gap and using hammer heads with a scraper structure to prevent clay adhesion. - Operating Performance: This equipment has been operating stably for over 3 years, with an average processing capacity of 25 tons/hour. The output particle size consistently remains below 80mm, effectively ensuring stable and high production for subsequent grinding mills. The customer highly praises its low failure rate and ease of maintenance.

Related Equipment Recommendations

To build a complete crushing production line, the PC600x400 usually needs to work in conjunction with other equipment:

- Front-end Feeding Equipment: A vibrating feeder (such as the GZD series) is recommended to feed the crusher evenly and continuously, maximizing its efficiency and preventing blockages.

- Subsequent Crushing and Screening: The crushed material can be fed into a PEX fine jaw crusher or impact crusher for secondary and fine crushing, and then classified by a circular vibrating screen to form a closed or open circuit.

- Conveying System: TD type belt conveyors are used to transport materials between different workstations.

Frequently Asked Questions (FAQ)

Q1: What is the maximum hardness of material that the PC600x400 crusher can handle?

A1: It is mainly suitable for medium-hard and softer materials with a compressive strength of no more than 200MPa. For harder materials (such as granite and river pebbles), a jaw crusher is recommended for primary crushing.

Q2: Must the feed size be strictly less than 150mm?

A2: Yes. Material exceeding the maximum feed size may cause equipment overload, abnormal wear of the hammer heads, or even damage. It is recommended to install a grizzly screen at the front end or have the excavator operator perform preliminary screening.

Q3: What is the service life of the hammer heads?

A3: This depends on the abrasiveness of the crushed material. For ordinary limestone, a single set of high-manganese steel hammer heads can last for several months. We offer various materials for hammer heads (such as high-chromium cast iron) for different working conditions.

Q4: How fine can the output particle size of the equipment be adjusted?

A4: By replacing the bottom screen plate with different aperture sizes, the minimum output particle size can reach approximately 10mm, but the processing capacity will decrease accordingly. The standard economic discharge size is 20-40mm.

Q5: Do you provide installation guidance?

A5: Absolutely. As a manufacturer with 20 years of experience, we provide comprehensive technical support, including foundation drawings, installation guidance, commissioning, and operator training, to ensure the equipment is put into operation quickly.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.