PE750x1060 jaw crusher is usually designed to handle medium to large-scale raw materials in the crushing industry, especially those scenarios that require a large crushing ratio and efficient crushing capacity.

For limestone and soft rock crushing plant needs of 150-200 tph, a PE750x1060 jaw crusher is a suitable choice, but the specific applicability also needs to consider the following factors:

1. Material characteristics: Limestone and soft rock are relatively soft and easy to crush, which makes the PE750x1060 jaw crusher able to effectively handle these materials. However, if the material contains a large amount of large pieces, hard impurities, or too high moisture, it may affect the crushing efficiency and machine wear.

2. Processing capacity: The design capacity of the PE750x1060 jaw crusher can usually cover the range of 150-200tph you mentioned, but the specific capacity will also be affected by factors such as feed particle size, material hardness, crushing chamber shape, and liner wear. Therefore, in actual applications, it may be necessary to adjust and optimize the operating parameters of the crusher according to the actual situation.

3. Equipment configuration and linkage: Crushing plants usually require multiple pieces of equipment to work together, including feeders, crushers, screening equipment, and conveyor belts. The PE750x1060 jaw crusher needs to be reasonably matched with other equipment to ensure the smooth operation and efficient output of the entire production line.

4. Maintenance and care: The long-term stable operation of the crusher is inseparable from good maintenance and care. Regularly checking the wear of the crusher, replacing worn parts, and adjusting the gap of the crushing chamber are all essential. In addition, reasonable operation and maintenance can also extend the service life of the crusher and reduce production costs.

5. Environmental protection requirements: With the increasingly stringent environmental protection regulations, crushing plants need to strictly control the emission of pollutants such as dust and noise during the production process. Therefore, when choosing a crusher, its environmental protection performance and supporting dust removal, noise reduction, and other equipment also need to be considered.

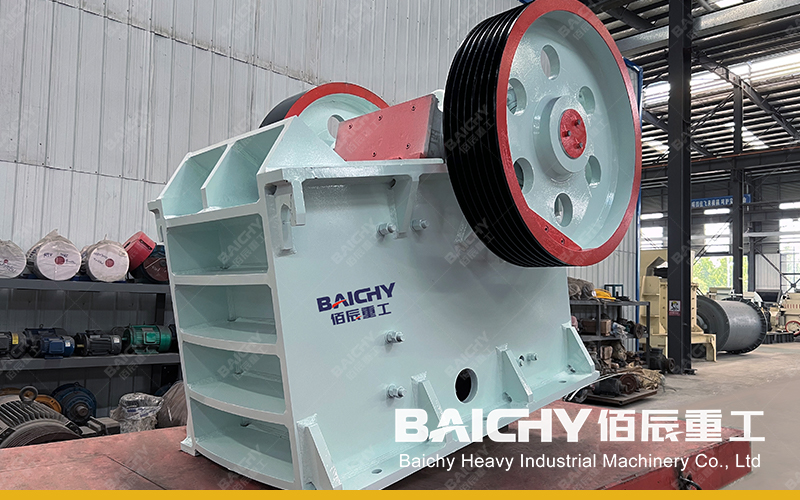

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.