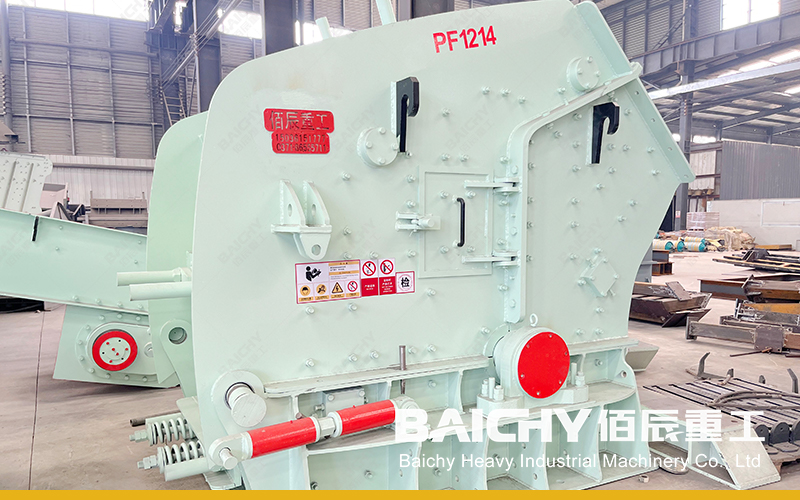

PF-1214 impact crusher is indeed a common and effective equipment in medium to large stone crushing plants, especially for those that need to process medium to high hardness materials such as limestone, granite, basalt, etc. For the production capacity requirement of 100-150t/h mentioned by you, the PF-1214 crusher can usually meet this requirement under proper configuration and operation.

Features of PF-1214 crusher

1. High-efficiency crushing capacity: Designed for medium to large-scale crushing operations, it can handle larger feed sizes and produce uniform crushed products.

2. High wear resistance: Key components such as impact plate and plate hammer are made of highly wear-resistant materials, which prolongs the service life of the equipment.

3. Flexible adjustment: By adjusting the gap between the impact frame and the plate hammer, the discharge particle size can be easily adjusted to meet different production needs.

4. Easy maintenance: The structural design is reasonable and easy to maintain, reducing downtime and maintenance costs.

Environmental performance: Some models are equipped with dust removal devices, which help to reduce dust emissions and improve the working environment.

Applicable scenarios of PF-1214 crusher

1. Stone crushing plant: used to produce construction aggregates, road paving materials, railway ballast, etc.

2. Mining: Preliminary crushing of ore in the mineral processing process.

3. Concrete mixing station: Provide qualified aggregates for the mixing station.

Precautions

1. Select suitable supporting equipment: including feeders, vibrating screens, conveyor belts, etc. to ensure the smooth operation of the entire production line.

2. Reasonable configuration of crushing ratio: According to the hardness and particle size of the raw materials, the crushing ratio of the crusher is reasonably configured to avoid excessive or insufficient crushing.

3. Regular maintenance and care: Regularly check the wear of the equipment, replace damaged parts in time, and ensure the long-term stable operation of the equipment.

4. Pay attention to environmental protection requirements: According to local environmental protection regulations, configure corresponding dust removal equipment to reduce dust emissions.

PF-1214 impact crusher has high application value in 100-150tph stone crushing plants, but the specific selection also needs to consider many factors such as raw material characteristics, production requirements, investment costs, and environmental protection requirements.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.