PF1214 Impact Crusher Machine For Mining

In the field of mining crushing, equipment efficiency and reliability directly impact the profitability of the entire production line. As a manufacturer of mining crushing equipment with twenty years of professional experience, we deeply understand the urgent needs of global mining customers for high-performance crushing solutions. The PF1214 mining impact crusher is a superior piece of equipment developed based on this need. It represents the latest advancement in impact crushing technology, integrating our two decades of profound experience in mining machinery design and manufacturing.

This medium-to-large-sized impact crusher is designed for secondary and tertiary crushing of medium-hardness ores. Its optimized rotor diameter to width ratio of 1:2.4 ensures that materials achieve the best impact angle and residence time within the crushing chamber. The equipment adopts a heavy-duty welded rotor structure, capable of withstanding high-intensity continuous operation, making it particularly suitable for the harsh environments of large-scale mining operations. We adhere to end-to-end quality control from raw material selection to final assembly, ensuring that every PF1214 unit delivers stable and reliable crushing performance at the customer's site.

| Key Words | PF1214 Impact Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤430mm |

| Motor Power | 132kw |

| Capacity | 100-180t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why choose the PF1214 impact crusher?

1. Superior Crushing Efficiency and Capacity Design

The core advantage of the PF1214 impact crusher lies in its highly efficient crushing capacity. The equipment employs an optimized crushing chamber design, capable of handling various ores with a maximum feed particle size not exceeding 350 mm, with a production capacity of 100-180 tons/hour. Specific output depends on material hardness and discharge particle size requirements. A unique impact plate and counter-impact plate angle adjustment system allows for product particle size adjustment without replacing major components, meeting the needs of different downstream processes.

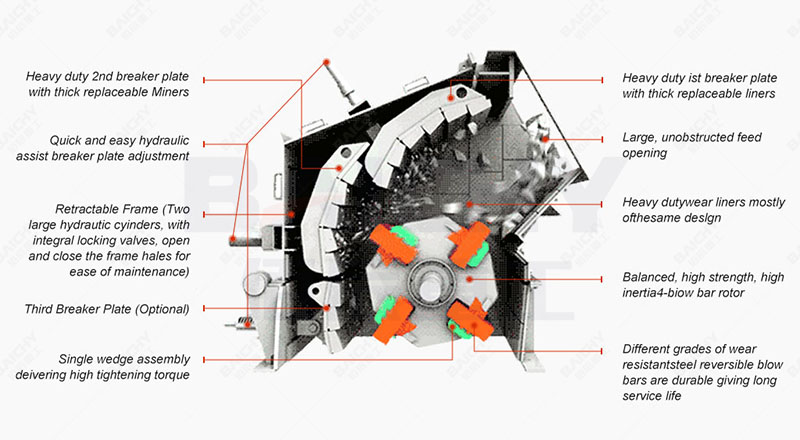

2. Advanced Structural Design and Durability

The rotor of the equipment adopts an integral cast steel structure and undergoes precise dynamic balancing testing, ensuring extremely low vibration levels even at high-speed rotation (rotor linear speed up to 40-50 m/s). We have specifically strengthened the bearing housing support structure and adopted heavy-duty roller bearings, significantly improving the service life of the equipment under impact loads. Wear parts such as the impact plates and counter-impact plates are made of high-chromium alloy materials, with wear resistance 2-3 times higher than ordinary manganese steel, significantly reducing customers' long-term operating costs.

3. Intelligent Control and Convenient Maintenance

The PF1214 is equipped with an intelligent monitoring system that can monitor bearing temperature, vibration parameters, and motor load in real time, providing early warnings of potential faults. The hydraulic opening device simplifies and speeds up internal inspection and maintenance, reducing tasks that traditionally took hours to complete to just tens of minutes. All maintenance points are ergonomically optimized to ensure technicians can perform routine maintenance safely and efficiently.

PF Impact Crusher Structure Diagram

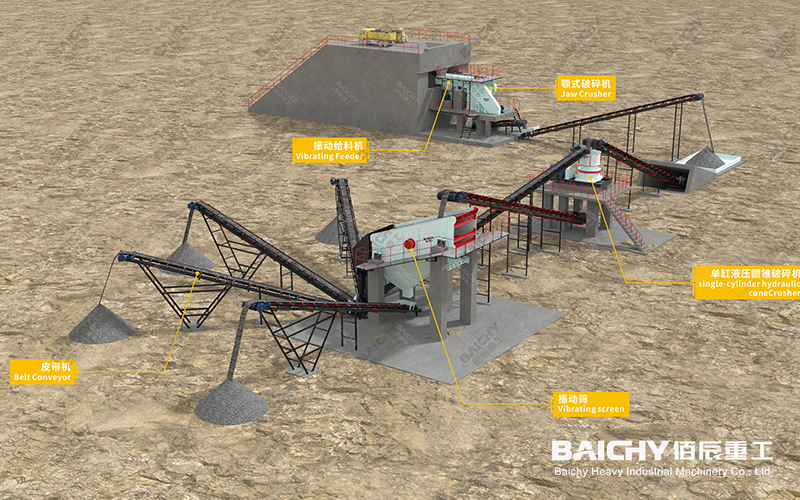

Diverse Application Scenarios: Comprehensive Mining Crushing Solutions

1. Metal Mine Crushing Systems

In metal mines such as iron, copper, and gold mines, the PF1214 is often used as a secondary crusher, further refining the ore after initial jaw crushing to the feed size required for ball mills or magnetic separation processes. Its efficient impact crushing principle is particularly suitable for processing ores with natural cleavage planes, maximizing crushing along mineral crystal boundaries and improving subsequent beneficiation recovery rates.

2. Building Materials and Aggregate Production

For the production of building aggregates such as limestone, granite, and basalt, the PF1214 can produce high-quality aggregates with excellent cubic shape and low needle-like and flaky content, fully meeting the stringent requirements for aggregate particle shape in high-end construction projects such as highways and high-speed railways. The multi-chamber design of the equipment allows the same machine to produce aggregate products of different specifications through simple adjustments.

3. Industrial Mineral Processing

In the processing of industrial minerals such as phosphate rock, potash, and quartz sand, the low-over-grinding characteristics of the PF1214 are particularly important. Compared to other compression crushers, impact crushing can better control the fine powder content and improve the yield of valuable products, making it particularly suitable for deep processing industries with strict requirements on product particle size distribution.

PF Impact Crusher Crushing Site

Global Project Cases: Actual Performance of the PF1214

1. Australian Iron Ore Project

In 2019, we supplied two PF1214 impact crushers to a large iron ore project in Western Australia to replace aging cone crushers. After two years of continuous operation, the equipment's average capacity reached 115% of its design value, energy consumption per ton of ore crushing decreased by 18%, and the proportion of qualified particle size in the product increased by 22%. The customer particularly appreciated the equipment's stability and ease of maintenance and plans to continue purchasing our equipment in its expansion project.

2. Southeast Asia Granite Aggregate Project

In a 2 million-ton-per-year high-quality aggregate production line in Vietnam, the PF1214 served as the core crushing equipment for processing high-strength granite. Despite the material's hardness reaching Mohs 7, the equipment maintained good condition for major wear parts after 8,000 hours of operation, and the cubic ratio of the aggregate product reached over 95%, fully meeting the stringent standards for local highway construction. The success of this project secured several follow-up orders for us in the Southeast Asian market.

3. South American Copper Mine Project

A large copper mining company in Chile selected our PF1214 in 2020 as an upgrade for its crushing system. We customized the lubrication system and electrical components to suit the customer's specific altitude and climate conditions. The equipment operates stably at a mine site at an altitude of 3800 meters, overcoming the impact of the low-oxygen environment on equipment performance and helping customers improve the overall availability of their crushing systems by 15 percentage points.

Aggregate crushing plant

Frequently Asked Questions (FAQ)

Q: What hardness of ore is the PF1214 suitable for processing?

A: The PF1214 is designed to process medium-hardness ores with a compressive strength not exceeding 350 MPa, such as limestone, dolomite, marble, granite, and most metallic ores. For materials with higher hardness, we recommend our specially designed ultra-hard rock crusher model.

Q: What is the expected service life of the equipment?

A: Under normal operation and regular maintenance, the main structure of the PF1214 has a service life exceeding 15 years. The lifespan of wear parts such as impact plates and counter-impact plates depends on the abrasiveness of the material, generally processing 80,000-120,000 tons of medium-hardness ore. We provide comprehensive wear monitoring guidance and predictive maintenance solutions to help customers maximize equipment lifespan.

Q: How is equipment support guaranteed in remote mining areas?

A: We have established a global three-tiered service network, including regional service centers, localized spare parts warehouses, and mobile service teams. In addition, we provide remote diagnostic systems and augmented reality technology support, enabling our experts to guide on-site personnel in resolving technical issues in real time, significantly reducing downtime.

Q: Does the equipment support automation upgrades?

A: Yes, the PF1214 was designed with future automation upgrade needs in mind. The equipment has reserved sensor interfaces and control system communication protocols, allowing for easy integration into plant-wide automation systems. We offer comprehensive automation solutions, from basic PLC control to AI-based predictive maintenance systems.

20 years of professional experience have given us a deep understanding of the global mining crushing needs. The PF1214 mining impact crusher is not just a piece of equipment, but an important component of the comprehensive solutions we provide to our customers. From equipment selection consultation and on-site installation guidance to long-term operational support, we are committed to helping global mining customers optimize their crushing processes, reduce operating costs, and improve ROI.

We believe that no matter where your mine is located in the world or what unique challenges it faces, our 20 years of technical experience and global project practice allow us to provide you with the most suitable crushing solution. Please feel free to contact our technical team to discuss how to integrate the PF1214 impact crusher into your production system and create greater value together.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.