100 T/H Limestone Crushing Production Line | PF1214 Impact Crusher Price

In the field of mining crushing, limestone, as a common non-metallic ore, is widely used in building materials, metallurgy, and chemical industries. For a limestone crushing production line with a capacity of 100 tons per hour, selecting efficient and reliable secondary crushing equipment is crucial.

As a manufacturer of mining crushing equipment with 20 years of experience, we recommend the PF1214 impact crusher as the core of the secondary crushing process, achieving high-efficiency production at the best price.

| Key Words | PF1214 Impact Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤430mm |

| Motor Power | 132kw |

| Capacity | 100-180t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Overview of the PF1214 Impact Crusher

The PF1214 impact crusher is a high-efficiency, energy-saving, medium-scale crushing equipment suitable for secondary crushing of medium-hardness materials such as limestone, gypsum, and coal gangue. Its rotor size is Φ1250×1400mm, the feed opening size is 400×1430mm, the maximum feed particle size is 350mm, and the processing capacity can reach 100-180 tons/hour, perfectly matching the needs of a 100-ton/hour limestone production line. This equipment adopts the impact crushing principle, producing finished particles with excellent shape and uniform particle size, and is equipped with a hydraulic opening device for easy maintenance.

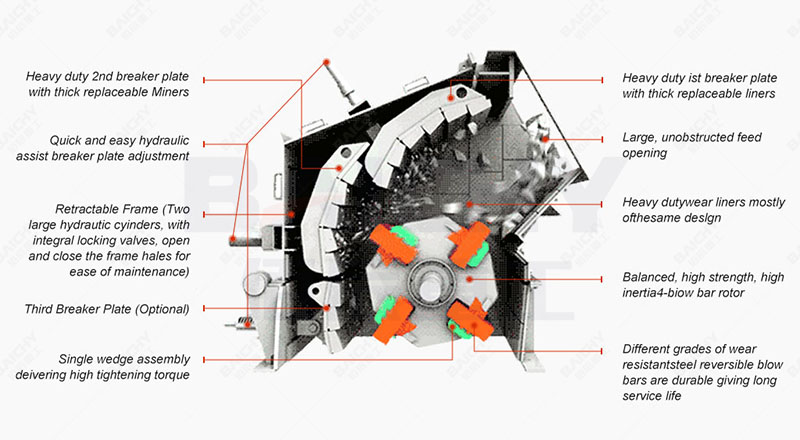

PF Impact Crusher Structure Diagram

II. Product Advantages: Why Choose PF1214?

1. High Cost-Effectiveness: PF1214 offers competitive pricing while maintaining high production capacity and finished product quality, reducing initial investment costs for customers.

2. High Efficiency and Energy Saving: Impact crushers have a large crushing ratio and low energy consumption, saving 20%-30% energy compared to traditional crushing equipment.

3. Excellent Finished Product Particle Shape: Crushed limestone particles are cubic with low needle-like and flaky content, suitable for high-standard building material production.

4. High Durability: Key components are made of high-chromium alloy wear-resistant materials, offering impact resistance, wear resistance, and a long service life.

5. Intelligent Control: Optional automation systems allow for remote monitoring and adjustment, improving production line stability.

PF Impact Crusher Crushing Site

III. Application Scenarios

The PF1214 impact crusher is widely used in limestone mines, cement plants, and aggregate production lines, especially suitable for:

• Secondary crushing of limestone to produce 0-30mm aggregate for concrete or asphalt mixtures.

• Forms a two-stage crushing system with a jaw crusher, achieving efficient linkage between coarse and fine crushing.

• Suitable for small and medium-sized mining projects, targeting clients seeking low costs and high returns.

IV. Project Case Study

In 2023, we provided a 100-ton/hour crushing production line for a limestone mine in Southeast Asia, with the PF1214 impact crusher as the core equipment. The production line configuration is as follows:

• Primary Crushing: PE600×900 Jaw Crusher

• Secondary Crushing: PF1214 Impact Crusher

• Auxiliary Equipment: Vibrating Feeder, Circular Vibrating Screen, Belt Conveyor, etc.

Operating results show that the production line achieves a stable capacity of 110 tons/hour, with over 90% of the finished product having a particle size of 0-25mm. The client's investment payback period was shortened to 12 months, and satisfaction was extremely high.

V. Frequently Asked Questions (FAQ)

Q1: What is the power consumption of the PF1214 crusher when processing 100 tons/hour of limestone?

A1: The motor power is 132kW. Actual operating power consumption varies slightly depending on the material hardness, with an average consumption of approximately 1.2-1.5 kWh/ton.

Q2: What is the replacement cycle for the wear parts?

A2: The hammerhead lifespan is approximately 3000-5000 hours, and the rotor guard plate can reach 6000 hours, depending on the silica content of the limestone.

Q3: What is included in the total production line price?

A3: We provide a turnkey solution, including design, equipment, installation guidance, and commissioning. The price is transparent with no hidden fees.

Q4: Do you support customized configurations?

A4: Yes, we can flexibly adjust the production line layout and equipment model according to the customer's site, budget, and finished product requirements.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.