The 100 t/h rock crushing production line is a highly efficient and versatile system that is suitable for crushing a variety of materials. This production line is specifically designed for processing hard rocks and minerals, making it ideal for mining operations, construction projects, and other industrial applications.

One of the main advantages of the 100 t/h hard rock crushing production line is its high production capacity. With the ability to process up to 100 tons of material per hour, this system is capable of handling large volumes of material quickly and efficiently. This makes it ideal for applications where a high level of production is required.

Another advantage of this production line is its versatility. It can be used to crush a wide range of materials, including hard rocks, granite, limestone, and more. This makes it a versatile solution for a variety of applications, from mining to construction to recycling.

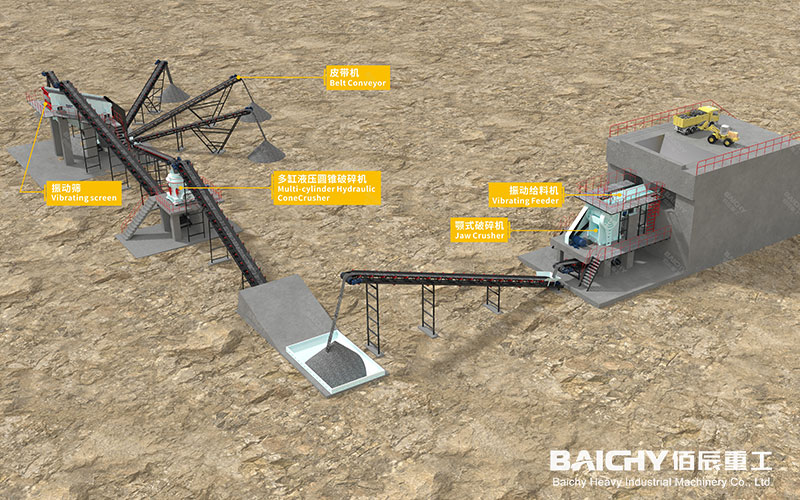

In order to operate the 100 t/h hard rock crushing production line, a number of key pieces of equipment are required. These include a primary jaw crusher, a secondary cone crusher, a vibrating feeder, a vibrating screen, and a belt conveyor. Each of these pieces of equipment plays a critical role in the overall operation of the production line, ensuring that materials are processed efficiently and effectively.

In particular, the cone crusher is a key component of the 100 t/h hard rock crushing production line. This type of crusher is well-suited for processing hard rocks and minerals, offering high crushing efficiency and a high degree of reliability. The cone crusher works by breaking down materials using a compressive force, which is ideal for processing hard rocks and minerals.

One of the key advantages of the cone crusher is its ability to produce a uniform particle size, which is crucial in ensuring the quality of the final product. Its powerful crushing mechanism can easily reduce large rocks into smaller pieces, facilitating further processing and refining.

Common types of cone crushers include spring cone crusher, hydraulic cone crusher, and compound cone crusher.

Spring cone crushers are equipped with springs to protect the crushing chamber against overload, while hydraulic cone crushers use hydraulic pressure to adjust the size of the discharge opening. Compound cone crushers combine the advantages of both spring and hydraulic cone crushers, offering a more efficient and reliable crushing process.

In conclusion, the cone crusher is a vital component in hard rock crushing production lines, providing efficiency, uniformity, and versatility. Its ability to crush tough materials with ease makes it an indispensable tool for industries that rely on hard rock materials for their operations.