Calcium carbonate powder grinding production line is a complete system specifically designed to process natural calcium carbonate ore into powders of varying finenesses. As an important industrial raw material, calcium carbonate powder is widely used in a variety of fields, including plastics, rubber, coatings, papermaking, building materials, and pharmaceuticals. A complete calcium carbonate powder grinding line typically includes multiple process steps, including crushing, grinding, grading, collection, and packaging. Core Equipment of a Calcium Carbonate Grinding Production Line

• Jaw Crusher: Used for primary crushing, breaking large calcium carbonate ore into smaller particles

• Impact Crusher/Cone Crusher: Used for secondary and tertiary crushing, further reducing the particle size

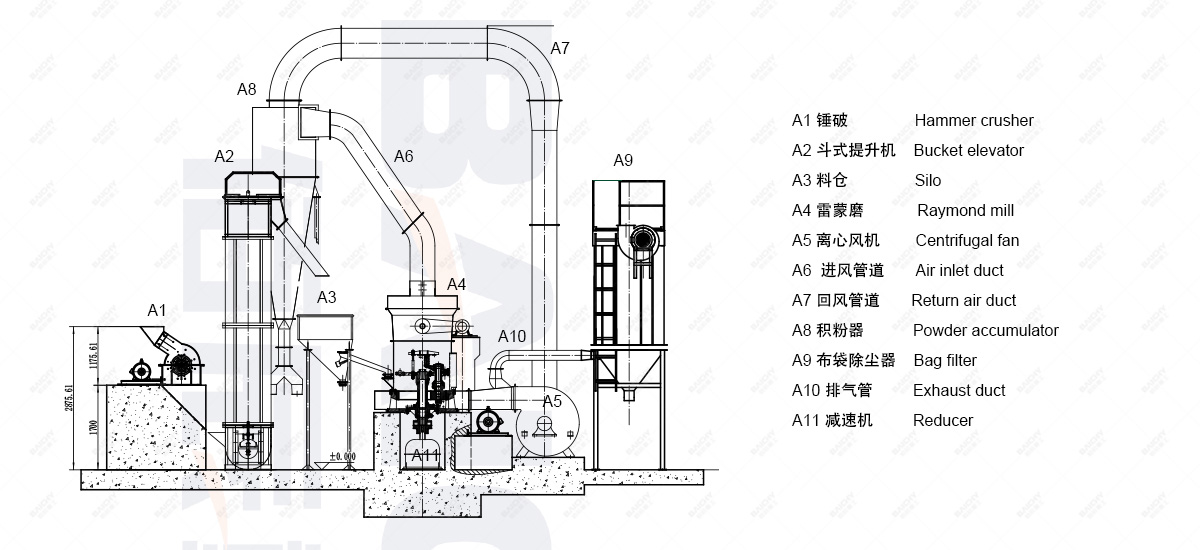

• Raymond Mill: Suitable for producing medium-fine powders of 200-400 mesh

• Vertical Mill: Highly efficient and energy-efficient, suitable for large-scale production of powders below 325 mesh

• Ball Mill: Used for producing ultrafine powders, reaching 600-2500 mesh

• Ultrafine Vertical Mill: Specialized in producing ultrafine powders above 1250 mesh

• Turbine Classifier: Precisely controls powder fineness

• Airflow Classifier: Suitable for fine classification of ultrafine powders

• Pulse Dust Collector: Efficiently collects finished powder

• Cyclone Separator: Initially separates powder from airflow

The YGM Raymond mill uses 30%-50% more energy than traditional grinding processes, significantly reducing electricity costs.

The production line is equipped with efficient classifying systems (such as turbine classifiers and air flow classifiers) that can flexibly adjust powder fineness (200-3000 mesh).

The entire line utilizes a pulse dust removal + cyclone collection system, achieving dust emission concentrations below 20mg/m³, far below environmental requirements.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery