Cement grinding is a key step in cement production, directly determining the fineness, strength, and energy efficiency of the finished product. With increasing national energy-saving and environmental protection requirements for the building materials industry, modern cement grinding production lines are developing towards high efficiency, low energy consumption, and intelligent technology.

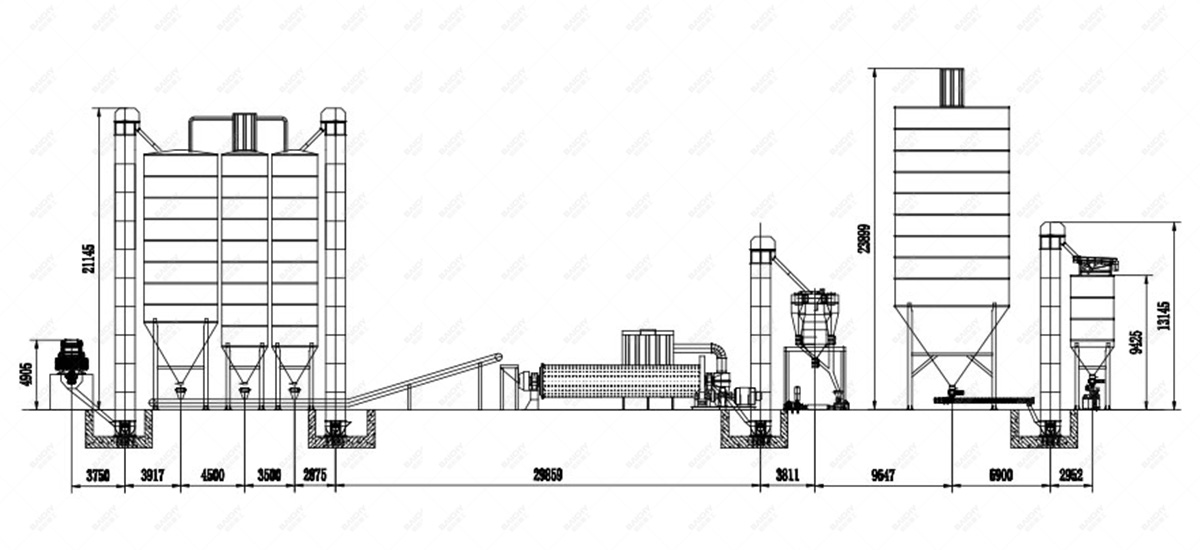

• Process: Raw material crushing → Pre-homogenization → Batching → Pre-grinding in roller press/vertical mill → Fine grinding in ball mill → Classification in classifier → Finished product storage

• Advantages: Energy consumption is reduced by 20%-30%, and the finished product fineness is adjustable (300-500 m2/kg), making it suitable for large-scale production.

• Features: No powder selection step, simple process, but higher energy consumption, suitable for applications where fineness requirements are less stringent. 3. Combined Grinding System

• Technology Combination: Roller Press + Ball Mill Working Together, Increases Production Capacity by 40%, Power Consumption ≤ 30kWh/t

| Type | Power Consumption (kWh/t) | Fineness Control | Investment Cost | Applicable Scale |

| Closed-Circuit System | 28-32 | Precision | High | Medium-Large Production Line |

| Open-Circuit System | 35-40 | General | Lower | Small/Specialty Cement |

| Combined System | 25-30 | Precision | Highest | Large Energy Saving Project |

• Ball Mill: Traditional equipment with strong adaptability but high energy consumption (accounting for over 50% of the total line's power consumption).

• Vertical Roller Mill (Vertical Mill):

Energy Saving Advantage: Power consumption is 15%-20% lower than a ball mill.

Integrated Functions: Combines grinding, drying, and powder selection, making it suitable for slag/cement composite grinding.

• Roller Press: The preferred choice for pre-grinding, offering high crushing efficiency and reducing the load on the subsequent ball mill.

• Feeding Equipment: Quantitative Feeder, Belt Scale

• Classification Equipment: Cyclone Classifier, O-Sepa High-Efficiency Classifier

• Dust Removal System: Pulse Bag Dust Collector (Emission ≤ 10mg/m³)

• Automation Control: DCS Central Control System (Real-time monitoring of production, energy consumption, and other data)

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery