In mining, aggregate production, and construction waste treatment, jaw crushers serve as the first line of defense in material crushing. Their stability and efficiency directly impact the operating costs and output of the entire production line.

Among numerous models, the 400x600 jaw crusher (with a feed opening of 400mm × 600mm) stands out as a star machine for small and medium-sized crushing production lines and stationary quarries due to its moderate processing capacity, wide applicability, and high return on investment.

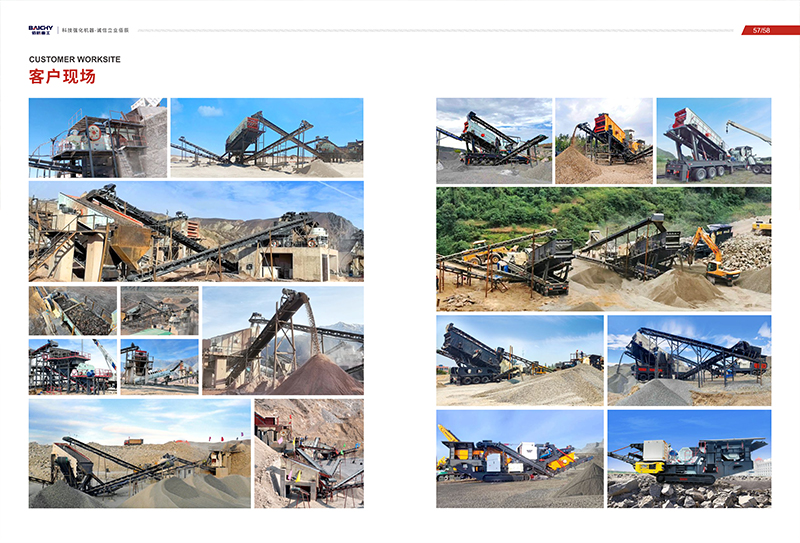

As a company with twenty years of experience in manufacturing mining crushing equipment, we understand our customers' core needs: to obtain the most competitive price while ensuring equipment quality, stability, and service life. Today, we will take you on a journey from a manufacturer's perspective to understand the value code behind a competitively priced 400x600 jaw crusher.

| Product Model | PE400x600 Jaw Crusher |

|---|---|

| Maximum Feed Size | ≤ 350 mm |

| Outlet Adiusting Range | 40-90 mm |

| Processing Capacity | 15-60tph |

| Motor Power | 30 kW |

| Core Structure | Deep cavity fracture |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Low Price Doesn't Equal Cheap: Cost Optimization Strategies Refined Through Twenty Years of Experience

A competitive price does not mean compromising on materials and processes. On the contrary, it is precisely based on our 20 years of accumulated technical expertise from thousands of crushing cases and our deep integration of the supply chain that we have been able to achieve scientific cost optimization.

• Structural Optimization Design: Leveraging our profound mechanical design skills and finite element analysis technology, we have strengthened and lightweighted the structural components of the equipment, such as the frame, moving jaw, and eccentric shaft. While ensuring sufficient rigidity and strength, we have reduced unnecessary material waste, lowering manufacturing costs at the source.

• Large-Scale Production and Supply Chain Management: A mature procurement system and large-scale production enable us to obtain high-quality raw materials (such as high-quality cast steel parts, bearings, and wear-resistant plates) at more favorable prices. This cost advantage resulting from economies of scale ultimately benefits our customers directly.

• Process Standardization and Efficiency Improvement: Twenty years of manufacturing experience means we possess mature and stable production processes and a skilled team of technicians. Standardized operations greatly improve production efficiency, reduce waste, and thus effectively control production costs.

II. Competitively Priced 400x600 Jaw Crusher with Uncompromised Core Performance

When choosing equipment, you need to focus on the following core elements, which are precisely where the value of our products lies:

1. Core Heart High-Strength Eccentric Shaft: We use a brand-new eccentric shaft forged from high-quality alloy steel and heat-treated. Its fatigue strength and wear resistance far exceed those of ordinary materials, ensuring stable operation of the equipment under heavy loads and significantly extending its service life.

2. Crushing Weapon High-Manganese Steel Jaw Plates: Both the moving and stationary jaw plates are made of ZGMn13 high-manganese steel and undergo water toughening treatment. Under severe impact and compression, it hardens rapidly, forming a hard and wear-resistant surface layer, making it particularly suitable for crushing high-hardness rocks and significantly reducing replacement frequency.

3. Stable Foundation Heavy-Duty Welded Frame: The frame is welded from high-quality steel plates, with reinforcing ribs added to key areas and stress-relief treatment. Its overall rigidity is high, not easily deformed, providing solid and reliable support for the entire machine and effectively resisting vibrations from crushing forces.

4. Adjustment Hydraulic Point Double Wedge Discharge Port Adjustment System: Compared to shim adjustment, the wedge adjustment method is faster, safer, and less labor-intensive. Customers can easily and quickly adjust the discharge port size to control the particle size of the finished product. Operation is simple and saves manpower.

III. Beyond the Equipment Itself: Hidden Value Packages Bring Long-Term Benefits

Choosing an experienced manufacturer means you get more than just a machine; you get a complete solution and long-term assurance.

• Scientific Selection Recommendations: We will provide you with the most suitable machine model recommendations based on your material characteristics (hardness, moisture content, mud content), expected output, and finished product requirements, avoiding underutilization or wasted investment.

• Convenient Spare Parts Supply: As the original manufacturer, we guarantee a long-term, fast supply of all vulnerable parts (such as jaw plates, side guard plates, etc.), with fully matched specifications and guaranteed quality, minimizing your downtime.

• Professional After-Sales Service: From equipment installation and commissioning to operator training, we provide comprehensive technical support. Our rapid-response after-sales team can resolve any issues that arise during production, giving you peace of mind.

A competitively priced 400x600 jaw crusher is a testament to the manufacturer's technological strength, management expertise, and market reputation. We firmly believe that true value means providing customers with a stable, durable, and reliable machine at a reasonable price, maximizing their return on investment.

We cordially invite you to visit our factory and witness firsthand our manufacturing processes and product quality. Let twenty years of professional expertise safeguard your efficient production.