60-80TPH Mobile Crusher for Crushing River Pebbles, Limestone, and Concrete

In the fields of mining, construction waste treatment, and infrastructure construction, the efficiency of on-site material crushing directly impacts project costs and schedules. Traditional stationary crushing production lines often fall short when faced with the hardness and abrasion resistance of river pebbles, the medium hardness of limestone, and the complex composition of concrete. How to achieve efficient, flexible, and low-cost crushing operations? This is precisely where mobile crushers with a capacity of 60-80 tons per hour shine.

As a manufacturer of mining crushing equipment with 20 years of professional experience, we deeply understand the challenges faced by mining customers worldwide. From quarries to urban construction waste recycling sites, from riverbank gravel processing to road construction sites, the persity of material characteristics, site conditions, and production needs demands that equipment possess exceptional adaptability. Based on this industry insight, we have developed a new generation of 60-80 tons/hour mobile crushers—more than just equipment, they are complete solutions for crushing challenges across multiple scenarios.

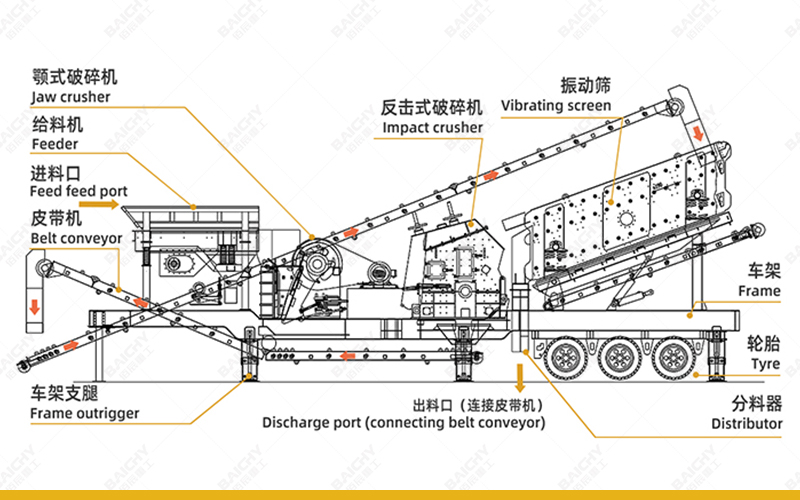

Four-unit mobile crushing plant structure diagram

Core Advantages: Multi-functional, Handling perse Materials

This mobile crusher was designed to break the limitations of equipment for crushing single materials. By optimizing the crushing chamber shape, adjusting the rotor speed, and selecting special wear-resistant materials, the equipment can intelligently adapt to the crushing characteristics of different materials:

• River pebbles: High hardness and high wear resistance; employs a layered crushing principle to reduce wear on wear-resistant parts.

• Limestone: Medium hardness; focuses on finished particle shape to produce high-quality aggregate.

• Concrete: Construction waste containing foreign objects such as reinforcing bars; equipped with a magnetic separator and a special anti-clogging design.

Technological Innovation: Flexible Mobility and Rapid Relocation

Compared to traditional fixed production lines, the biggest advantage of mobile crushers lies in their mobility. The entire machine adopts a vehicle-mounted design, requiring no complex infrastructure construction; it can be put into production immediately upon arrival and connection to a power source. This saves significant preparation time and relocation costs for projects with multiple dispersed work sites, short-term projects, or site-constrained urban operations.

Energy-Saving, Highly Efficient, Stable, and Reliable

The equipment is equipped with an advanced intelligent control system that can monitor key parameters such as crusher load, bearing temperature, and vibration values in real time, automatically adjusting the feeding speed and crushing intensity to minimize energy consumption while ensuring throughput. Verification has shown that this equipment can stably process 60-80 tons of material per hour under full load operation, with energy consumption reduced by approximately 15% compared to similar products.

Technical Parameters and Configuration Details

To provide you with a more comprehensive understanding of the performance of this equipment, the following is a table of its main technical parameters and configuration:

| Item | Parameter/Configuration | Description |

| Processing Capacity | 60-80 tons/hour | Fluctuates according to material density and feed particle size |

| Applicable Materials | River pebbles, limestone, concrete, construction waste, etc. | Compressive strength ≤350MPa |

| Feed Particle Size | ≤500mm |

Adjustable, maximum not exceeding the feed inlet size |

| Discharge Particle Size | 0-40mm adjustable | Multiple finished product specifications, controlled by screening equipment |

| Power Configuration | Diesel generator set/mains dual mode | Adaptable to different sites with and without power grid |

| Mobility | Vehicle-mounted towing |

Can be towed by standard semi-trailer, small turning radius |

| Control System | PLC intelligent touch screen control | With remote monitoring interface, self-diagnosis of faults |

| Environmental Standards | Enclosed design, equipped with dust removal and noise reduction systems | Compliant with EU CE and other international environmental requirements |

Global Mining All-Scenario Solution Provider

For twenty years, we have adhered to the principle of "equal emphasis on equipment and service." In addition to providing high-performance crushing equipment, we offer global clients a full range of services, including site surveys, solution design, installation and commissioning, operation training, and after-sales support. Whether you are in a mine in Africa, a quarry in Southeast Asia, or a construction waste recycling project in Europe, our engineering team can provide you with localized professional support.

In today's world where sustainable development is a global consensus, efficient and environmentally friendly crushing equipment is not only a tool to improve economic efficiency but also a manifestation of fulfilling environmental responsibility. Our mobile crushers excel in resource recovery, reducing carbon emissions from transportation, and minimizing noise and dust pollution, helping clients achieve their green production goals.

Choosing our 60-80 ton/hour mobile crushers means you're not just getting a piece of equipment, but a reliable partner capable of adapting to various harsh working conditions, handling perse materials, and being ready for relocation at any time. Let us leverage our twenty years of professional experience to provide the most competitive solutions for your crushing operations.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.