Dehydration screensplay a vital role in industrial production. Their high-efficiency screening and precise dehydration characteristics have brought significant optimization and improvement to the production processes of many industries.

1. Dewatering screen - high-efficiency screening

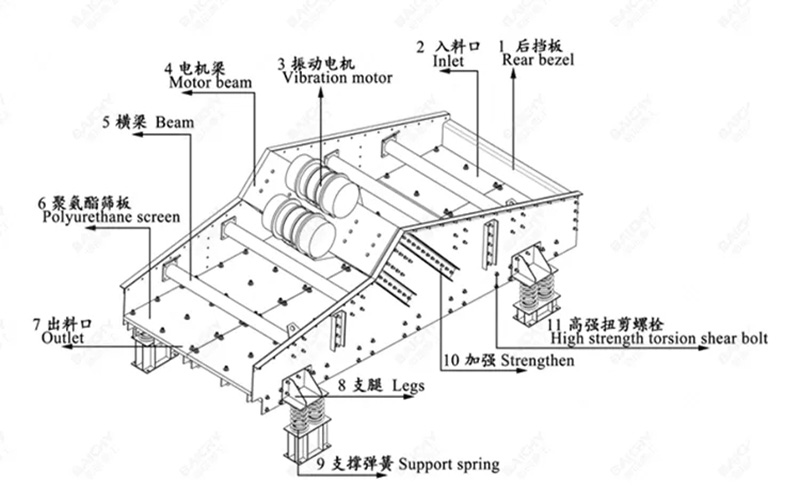

Powerful processing capacity: The dewatering screen has a large screen area and reasonable design. It can handle a large amount of materials at one time and has a strong processing capacity. This enables it to easily cope with large-scale production tasks and ensure the continuous and stable operation of the production line.

High screening accuracy: The dewatering screen uses a high-precision screen mesh and uses carefully adjusted vibration modes to make the material move more uniformly on the screen surface, thereby effectively removing impurities and unqualified particles in the material. This high-precision screening effect not only ensures product quality but also reduces the difficulty and cost of subsequent processing.

Strong adaptability: The dewatering screen can adjust the vibration frequency and amplitude according to the properties of the material and screening needs to achieve the best screening effect. This flexibility allows the dewatering screen to be widely used in a variety of material screening scenarios in different industries.

2. Dehydration screen - precise dehydration

Good solid-liquid separation effect: The dewatering screen uses the vibration and tilt of the screen to cause the materials to continuously jump and tumble on the screen, thereby achieving the purpose of solid-liquid separation. The moisture in the material is gradually separated during the screening process, while the solid material moves forward along the screen and is finally discharged from the discharge port.

Reduce the moisture content: Through the processing of the dewatering screen, the excess moisture in the material can be effectively removed, significantly reducing the moisture content of the material. This is of great significance for improving the subsequent processing efficiency of materials and product quality.

Improve material quality: The precise dehydration function of the dewatering screen allows the useful ingredients in the material to be better retained and utilized, and at the same time removes moisture and impurities that affect the quality, thus improving the overall quality of the material.

3. Dewatering screen - widely used

Dewatering screens are widely used in a variety of industries, including but not limited to:

Mining industry: used to screen ore, gangue and other materials to improve the quality and utilization of materials.

Coal industry: Screen coal, coal slime and other materials to reduce moisture and ash content, and improve the calorific value and combustion efficiency of coal.

Metallurgical industry: screening slag, slag and other materials to recover valuable metal elements.

Building materials industry: screening sand, gravel, limestone and other materials to improve the uniformity and quality of materials.

Chemical industry: In the chemical production process, materials that require solid-liquid separation are dehydrated.

4. Dewatering screen - energy saving and environmental protection

During the working process, the dewatering screen achieves dehydration of materials through vibration and screening without additional energy consumption and chemical treatment and has the advantages of energy saving and environmental protection. At the same time, its efficient screening and dehydration effects also reduce the difficulty and cost of subsequent processing, contributing to the sustainable development of the enterprise.

Dewatering screens play an important role in industrial production due to their characteristics of efficient screening and precise dehydration. It not only improves the quality and utilization of materials but also reduces production costs and environmental pollution, providing strong support for the production and development of enterprises.

Service Guarantee

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.