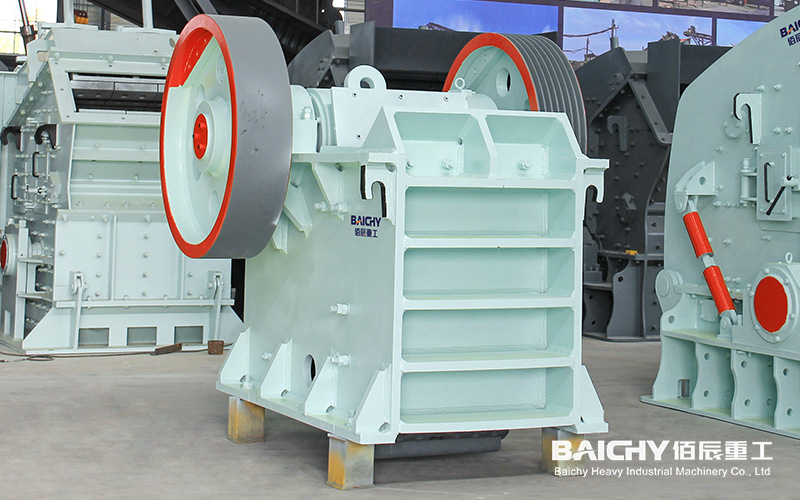

PE500×750 Jaw Crusher Manufacturer | High-Efficiency Primary Crushing Equipment

The topic PE500×750 Jaw Crusher clearly points to a core primary crushing equipment in the mining and crushing industry. PE stands for Jaw Crusher, 500 indicates a feed opening width of 500mm, and 750 indicates a feed opening length of 750mm.

This model is widely used in small and medium-sized mines, stone quarries, and construction waste processing projects. With its stable performance, reasonable processing capacity, and high cost-effectiveness, it has become a mainstay in the industry.

| Key Words | PE500×750 Jaw Crusher Manufacturer |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤425mm |

| Motor Power | 45kw |

| Capacity | 40-130t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

The PE500×750 jaw crusher adopts a mature oscillating jaw crushing principle, featuring a robust structure and reasonable design. Main components such as the frame, movable jaw, and eccentric shaft are made of high-quality steel and undergo heat treatment to ensure high durability and impact resistance when crushing high-hardness materials. Its maximum feed size can reach 425mm, the discharge opening adjustment range is 50-100mm, and the processing capacity can reach 40-110 tons/hour, with a motor power of 55Kw, perfectly matching the needs of medium-scale crushing operations. Its deep crushing chamber design not only improves feeding capacity but also optimizes crushing efficiency.

Core Advantages: Excellent Performance Forged with 20 Years of Expertise

1. High Reliability and Stable Operation: With 20 years of manufacturing experience, we strive for excellence in casting processes, assembly precision, and the selection of core components (such as bearings and jaw plates), ensuring continuous and stable operation of the equipment under harsh working conditions, significantly reducing unexpected downtime.

2. High Crushing Ratio and Outstanding Efficiency: The optimized cavity design allows for more effective compression and crushing of materials within the crushing chamber, resulting in a high single-machine crushing ratio and uniform product particle size, creating favorable conditions for subsequent secondary and tertiary crushing processes.

3. Simple Maintenance and Low Operating Costs: The simple structural design makes maintenance and replacement of wear parts (such as jaw plates) easy. The lubrication system is safe and reliable, and daily maintenance is convenient, effectively helping customers control long-term operating costs. 4. Energy-saving, environmentally friendly, and highly adaptable: The equipment has low power consumption and, combined with dust control design, better meets the environmental protection requirements of modern production. It can be widely used for crushing various materials such as granite, basalt, river pebbles, and limestone.

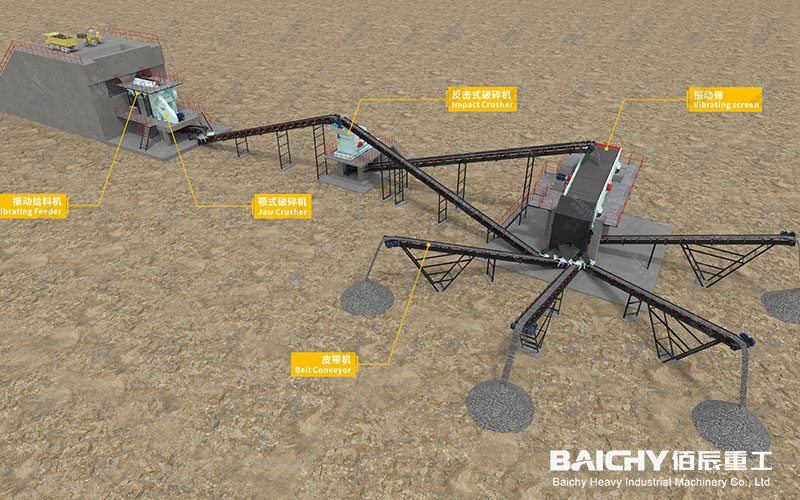

PE500x7500 Jaw Crushing Plant

Application Cases: Success Stories from Global Customers

Case 1: A Large Sand and Aggregate Project in East China

The customer used a PE500×750 as the primary crusher for limestone raw materials. Since its commissioning in 2018, the equipment has operated for an average of 12 hours a day, with an annual processing capacity exceeding 250,000 tons. It operates stably, and the output particle size fully meets the feeding requirements of the downstream impact crusher, earning high praise from the customer.

Case 2: A Mining Project in Southeast Asia

In the local high-temperature and high-humidity environment, our PE500×750, with its excellent anti-corrosion treatment and heat dissipation design, was successfully applied to the primary crushing of iron ore. The production capacity consistently met the standards, demonstrating its excellent environmental adaptability.

Jaw Crushing Plant

Related Equipment Recommendations

A complete crushing production line, in addition to reliable primary crushing equipment, also requires efficient supporting equipment:

Secondary and Fine Crushing Recommendations: PF series impact crushers or HPY series multi-cylinder hydraulic cone crushers are recommended for secondary crushing of materials to obtain finer finished products.

Feeding and Screening: ZG series vibrating feeders and YA series circular vibrating screens ensure continuous, uniform, and efficient grading operations of the production line.

Mobile Crushing Station: If you have needs for relocation or multi-point operation, we can provide wheeled or tracked mobile crushing stations integrated with the PE500×750 jaw crusher.

Frequently Asked Questions (FAQ)

Q1: What is the maximum feed size of the PE500×750?

A1: The maximum feed size is approximately 425mm. This may vary slightly depending on the hardness of the material. It is recommended to keep the feed size below 350mm for optimal efficiency and liner life.

Q2: What is the typical service life of the jaw plates (toothed plates)?

A2: This depends on the hardness, abrasiveness, and throughput of the material being crushed. For medium-hard limestone, under normal use and maintenance, a set of jaw plates typically lasts 6-12 months. We offer jaw plates made of various materials (such as high-manganese steel and alloy steel) for customers to choose from.

Q3: Does the equipment require special foundation construction?

A3: Yes. Jaw crushers generate significant vibration during operation and require a sturdy concrete foundation. We will provide detailed foundation drawings and load requirements to guide customers in foundation construction, which is crucial for the stable operation of the equipment.

Q4: Can you provide installation guidance and technical support?

A4: Absolutely. As a manufacturer with 20 years of experience, we provide comprehensive technical support services, from foundation survey and process design to installation and commissioning, operation training, and after-sales maintenance.

Q5: What factors determine the fluctuation range of the processing capacity 40-110 t/h?

A5: The processing capacity is affected by the material hardness, moisture content, feed particle size distribution, and the size of the discharge opening. Softer, more uniformly sized materials, with a wider discharge opening, will result in a throughput closer to the upper limit; conversely, it will be closer to the lower limit.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.