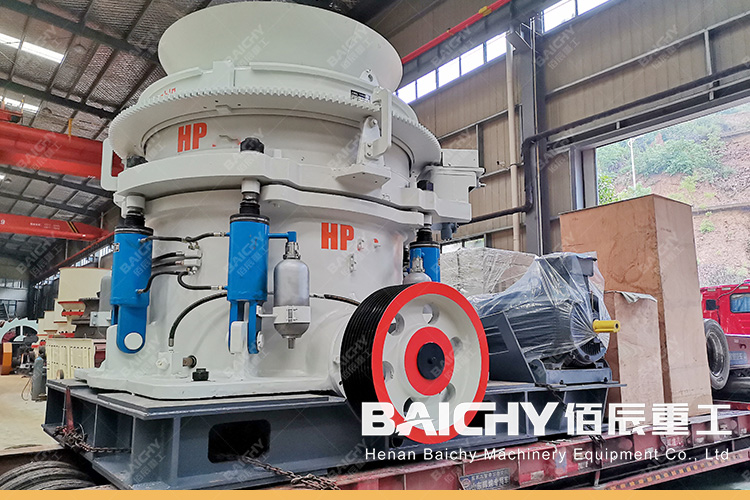

The multi-cylinder hydraulic cone crusher sent by Baichy to Russia is equipped with a hydraulic oil station, refrigeration system, etc.

About of multi-cylinder hydraulic cone crusher price

Multi-cylinder hydraulic cone crusher is mainly used for secondary crushing or tertiary crushing in aggregate sand and gravel processing. This machine has advantages in crushing hard materials and fine crushing and is widely used in metal and non-metallic ores: such as iron ore, manganese ore, chromium ore, copper ore, lead-zinc ore, gold ore, silver ore, bauxite, etc.; Building stones: such as limestone, marble, granite, basalt, river pebbles, cobblestones, etc.

The hydraulic cone crusher launched by Baichy Heavy Industry adopts the stacking principle. Through the special crushing cavity shape and layered crushing principle, a crushing effect is generated between particles, thereby achieving the crushing of materials. It has the advantages of high crushing efficiency, large crushing ratio, uniform particle size, and low energy consumption, and can be adapted to crushing operations with different particle size requirements. At the same time, the hydraulic cone crusher has a larger feed inlet than ordinary cone crushers, high time production capacity, and good environmental protection, so it has been widely used in many industries.

Multi-cylinder hydraulic cone crushers also have some shortcomings, such as complex structure, high cost, and difficult maintenance. In addition, it is not suitable for crushing wet and sticky ores, nor is it suitable for processing soft ores, and is prone to excessive stone powder.

Advantages of HPC-300 multi-cylinder hydraulic cone crusher

The HPC-300 multi-cylinder hydraulic cone crusher has several significant advantages. Here are some of the main features:

1. Thin oil lubrication system: This crusher adopts a unique thin oil lubrication system design, which greatly improves the service life of the equipment. Thin oil lubrication can better protect the internal parts of the equipment and reduce wear, thus extending the overall service life of the equipment.

2. Hydraulic protection: Hydraulic adjustment of the discharge port and overload protection greatly improve the operation level of the cone crusher. When the equipment encounters overload or blockage, the hydraulic system will automatically adjust or shut down to avoid equipment damage, while also making maintenance simpler, operation more convenient, and downtime shorter.

3. Easy maintenance: HPC cone crusher only needs to replace the fixed cone lining plate and the moving cone lining plate. The crushing cavity type can be changed from ultra-coarse cavity type to short-head ultra-fine cavity type to adapt to a wide range of product particle size requirements. This design makes it easier to repair and replace parts of the equipment, improving the availability of the equipment.

4. Reasonable structure and reliable operation: The crusher has a reasonable structure, reliable operation and low operating cost. The special crushing cavity designed based on the laminated crushing principle and its matching rotation speed can produce excellent finished product particle shape, replacing the traditional single particle crushing principle.

5. Large crushing ratio and high production efficiency: HPC-300 multi-cylinder hydraulic cone crusher has a large crushing ratio, can handle ores and rocks of various hardness, and has high production efficiency.

6. Strong adaptability: Since the crushing cavity type can be changed at will, the HPC-300 multi-cylinder hydraulic cone crusher can adapt to various product particle size requirements and has strong adaptability.

7. Easy to operate: The crusher adopts an advanced control system, which can realize automated operation, reduce manual intervention, and reduce the difficulty of operation.

HPC-300 multi-cylinder hydraulic cone crusher has many advantages such as thin oil lubrication, hydraulic protection, convenient maintenance, reasonable structure, large crushing ratio, strong adaptability and easy operation, making it popular in fields such as ore processing and building material crushing. widely used.

Frequently asked questions about cone crushers

Regarding cone crushers, common questions may include the following aspects:

1. Oil temperature is too high:

● Reason: It may be caused by cooling system failure, insufficient or contaminated lubricating oil, oil pump failure, etc.

● Solution: Check the cooling system, make sure the lubricating oil is sufficient and clean, and check the oil pump and its working condition.

2. Oil pressure problem:

● The oil pressure is low or the indicator has no oil flow after the oil pump is started: it may be due to low oil temperature, blockage of the oil pipe, or abnormal operation of the oil pump.

● Abnormal rise in oil pressure: It may be due to blockage of the internal oil circuit, failure of the oil pump, or failure of the safety valve.

● Solution: Check the oil temperature, oil pipe, and oil pump, clean or replace blocked parts, and check and adjust the safety valve.

3. Oil quality issues:

● The oil contains a large amount of fine mud and impurities: it may be due to failure of the sealing and dust-proof device, blockage, or leakage of the water pipe, resulting in lack of water.

● There is water in the oil and the oil level in the fuel tank is rising: it may be due to a leak in the cooler or a loose seal in the fuel tank.

● Solution: Shut down to re-seal or clean and repair, replace with new oil, check and repair leaks in the cooler and fuel tank.

4. Crusher vibration:

● Strong vibration: It may be caused by the loose fixing device of the machine base, difficult-to-break materials entering the crushing cavity, excessive material in the crushing cavity-causing material blockage, broken or worn accessories, poor lubrication causing the main shaft to be tightly packed by the bushing, etc.

● Solution: Tighten the bolts and pour; control the type of feed and strictly prohibit non-crushed objects from entering; strictly control the amount of feed; stop the machine to check accessories; replace damaged parts, and overhaul the oil pump and pipelines.

5. Driveshaft problem:

● The drive shaft rotates unevenly and produces a strong knocking sound: it may be due to severe wear or damage of the gear, a damaged coupling key, or a broken spindle.

● Solution: Stop the machine replace the gear make the meshing clearance meet the requirements; replace the connecting key; replace the spindle and strengthen iron removal work.

6. Noise problem:

● Audible cracking sounds when crushing or idling: It may be caused by the impact due to a loose lining plate or out-of-round moving cone or fixed cone lining plate.

● Solution: Stop the machine to check the tightening of the screws and the peeling of the zinc layer, and repair or replace related parts.

7. Downtime issues:

● After the knocking sound, the coupling rotates but the crusher does not move: it may be due to the key of the transmission coupling or gear being broken, or the main shaft being broken.

● Solution: Replace the transmission coupling or gear key, and replace the spindle.

The above are some common problems that cone crushers may encounter and their solutions for your reference. If you encounter complex or unsolvable problems, it is recommended to contact professional maintenance personnel or the equipment manufacturer.