Impact Crusher Vs. Hammer crusher

Both impact crushers and hammer crushers use the impact principle to crush materials, and the product has excellent particle shape and similar appearance.

However, there are significant differences in structural principles, crushed materials, product appearance, use and configuration, energy consumption, and wearing parts. When selecting equipment, it is necessary to comprehensively consider factors such as specific production needs, material characteristics, and economic benefits.

So how should we choose to use an impact crusher or hammer crusher?

1. Different structural principles

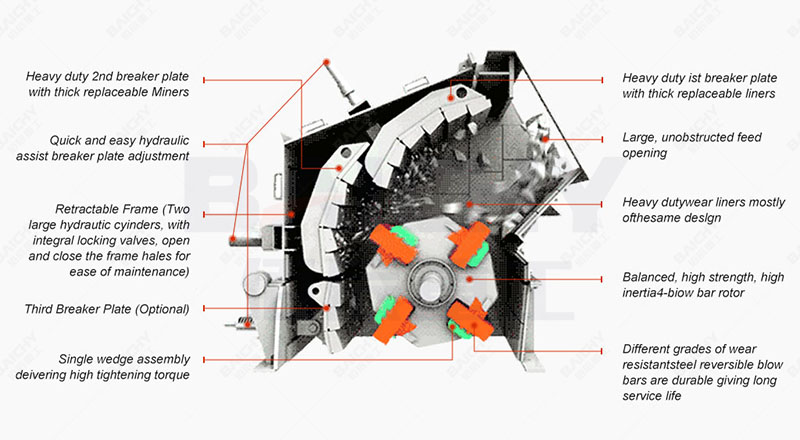

PF Impact Crusher Structure Diagram

Impact crusher: mainly composed of rotor, plate hammer, impact plate, frame, impact plate, transmission parts, etc. Its crushing principle uses impact energy to crush materials. The materials enter the first, second, and third impact chambers from large to small and are repeatedly crushed until the materials are crushed to the required particle size. The impact crusher has a larger crushing chamber, which allows the material to have a certain activity space and fully utilize the impact effect. The impact crusher is a multi-cavity crushing structure that is more fully crushed.

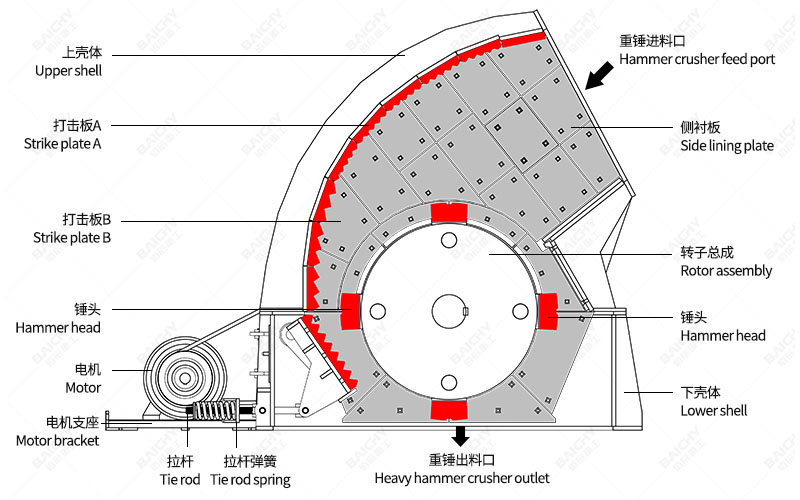

Hammer Crusher Structure Diagram

Hammer crusher: It is composed of rotor, hammer head, hammer frame, pin shaft, frame, crushing plate, screen plate, transmission parts, etc. Its crushing principle uses the high-speed impact of the hammer to perform medium and fine crushing of the material. The crushing chamber of the hammer crusher is small, the impact effect cannot be fully exerted, and the hammer crushes the material inpidually, so the speed and kinetic energy obtained by the material are limited.

2. Different crushed materials

Impact crusher: It is suitable for processing materials with higher hardness, such as granite, river pebbles, etc. Its feed particle size is generally less than 500 mm, and its compressive strength can reach 350MPa.

Hammer crusher: It is generally suitable for medium hardness and brittle materials, such as limestone, coal gangue, etc. Its feed particle size is generally less than 1200 mm, and its compressive strength is less than 200MPa.

3. Different product particle shapes

Impact crusher: Its product particle shape is cubic particles, with low fine powder and dust content, and uniform discharge particle size.

Hammer crusher: This product has more flaky stones and a high powder content.

4. Different uses and configurations

Impact crusher production line customer site

Impact crusher: It is mostly used as a secondary crushing equipment, often used in conjunction with a jaw crusher, and is used in the medium and fine crushing stages of a stone production line. The feed size of the impact crusher should not be too large, and it needs to be used in conjunction with a primary crusher.

Hammer crusher production line customer site

Hammer crusher: It can directly feed large materials for crushing, and the crushing is relatively large, which can achieve a combination of coarse and fine crushing. In cement production lines, hammer crushers can be used as limestone raw material crushing equipment, and can also be used as primary crushing equipment in sand and gravel co-production projects.

5. Different energy consumption and wearing parts

Impact crusher: The same model of impact crusher is more energy-efficient than hammer crusher, and its wearing parts are durable and have a lower maintenance frequency. The plate hammer and rotor of the impact crusher are rigidly connected, with high metal utilization, and the discharge particle size can be adjusted in a variety of ways, such as adjusting the rotor speed, adjusting the gap between the impact plate and the plate hammer, etc.

Hammer crusher: The hammer head and grate bars wear faster, the metal consumption is large, and the maintenance time is longer. The hammer head of the hammer crusher is in a suspended state, and wear occurs on the top, front, back, and sides. The metal utilization rate of the hammerhead is relatively low. The adjustment of the discharge particle size is mainly achieved by replacing the bottom screen plate.

6. Different equipment prices

The prices of the two equipments vary depending on factors such as equipment output, model size, and manufacturer selection. For specific prices, please consult the relevant manufacturers to obtain the factory quotation sheet.

Impact crusher price: $1, 000 (the lowest price).

Hammer crusher price: It has many models with the lowest price of $976. Among them, the heavy hammer crusher has a larger granularity and is sold for $5, 000-$180, 000.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.