Iron ore crushing production line and iron ore crusher plays a vital role in the iron ore processing process. Here’s a detailed introduction to both:

1. Iron ore crushing production line

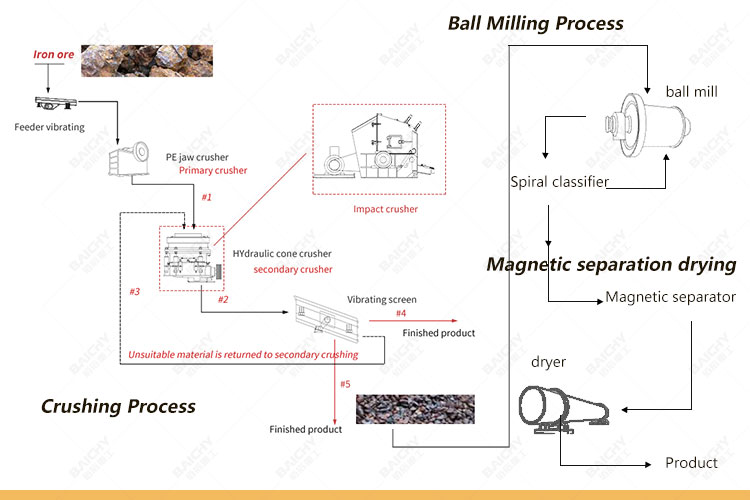

The iron ore crushing production line is a complete iron ore processing system, used to crush the mined iron ore raw ore into the required particle size. It usually consists of the following parts:

Feeding equipment: such as a vibrating feeder, which is used to feed raw iron ore into the crusher evenly and continuously.

Crushing equipment: mainly including jaw crusher, cone crusher, etc. The jaw crusher is suitable for coarse crushing operations and can break large pieces of iron ore into smaller particle sizes; the cone crusher is suitable for medium and fine crushing operations and can further crush iron ore into the required particle size.

Screening equipment: such as vibrating screens, used to screen crushed iron ore according to particle size to meet different process requirements.

Conveying equipment: such as belt conveyors, used to transport crushed iron ore to the next process or storage location.

The design of an iron ore crushing production line needs to consider many factors, such as the properties of raw ore, particle size requirements, production capacity requirements, equipment selection, etc. Through reasonable configuration and optimization, efficient, low-consumption, and environmentally friendly iron ore crushing operations can be achieved.

2. Iron ore crusher

The iron ore crusher is one of the core equipment of the iron ore crushing production line. It is used to crush the raw iron ore into the required particle size. Common iron ore crushers include jaw crushers, cone crushers, impact crushers, etc.

Jaw crusher: Utilizes the relative motion of the movable jaw and the static jaw to crush the materials entering the crushing cavity by squeezing, shearing and bending. Jaw crusher has the advantages of simple structure, reliable operation and convenient maintenance. It is widely used in crushing iron ore of various hardness.

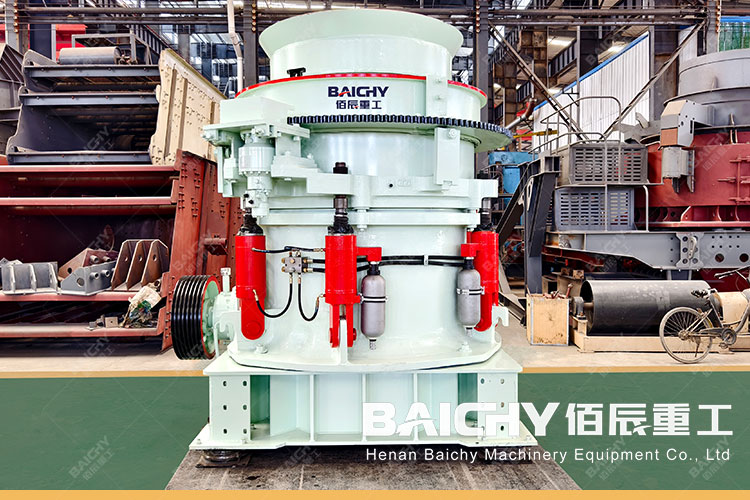

Cone Crusher: Squeeze and crush materials through a rotating cone. Cone crusher has the advantages of a large crushing ratio, high efficiency and low energy consumption, and is suitable for medium and fine crushing operations.

Impact crusher: uses the plate hammer on the high-speed rotating rotor to impact and crush the materials. The impact crusher has the advantages of high crushing efficiency, uniform particle size, and low energy consumption, and is suitable for processing medium-hard iron ore.

When selecting an iron ore crusher, it is necessary to comprehensively consider factors such as the nature of the raw ore, particle size requirements, and production capacity requirements to select the most suitable equipment model and configuration. At the same time, you also need to pay attention to the maintenance and upkeep of the equipment to ensure its normal operation and extend its service life.