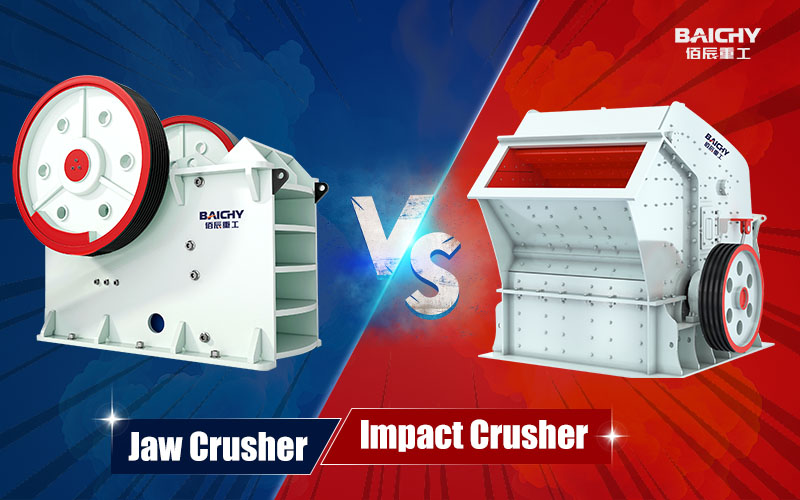

In sand and gravel aggregate and mining crushing production lines, selecting the appropriate primary (first-stage) crushing equipment is crucial to determining the efficiency, cost, and final product quality of the entire production line. Jaw crushers and impact crushers are two common types of crushing equipment, but their applicable scenarios differ significantly.

Core Conclusion: For demanding primary crushing conditions, jaw crushers are a more common and suitable choice. Impact crushers are generally not used as the first-stage crushing equipment unless the material has low hardness and specific product particle shape requirements.

I. Why is the Jaw Crusher the Absolute Mainstay of Primary Crushing?

Jaw crushers utilize the principle of "compression between the moving jaw and the fixed jaw" for crushing, and their advantages perfectly match the needs of primary crushing:

1. Powerful crushing force and adaptability to high-hardness materials: With a robust and simple structure, it can easily handle various hard materials with compressive strengths up to 350MPa (such as granite, basalt, quartz, etc.).

2. Large feed opening: Allows direct input of large pieces of raw ore (feed particle size can reach over 1500mm), a basic requirement for primary crushing equipment.

3. Stable operation and easy maintenance: The equipment is durable, has a low failure rate, and a long maintenance cycle, making it suitable for continuous operation in harsh mining environments.

4. High cost-effectiveness: Compared to other primary crushing equipment with the same processing capacity, the initial investment is usually more advantageous.

Applicable scenarios: Almost all situations requiring primary crushing of large ore blocks, especially mines and large aggregate plants where materials are hard and highly abrasive.

II. What are the limitations of impact crushers in primary crushing?

Impact crushers use the principle of "high-speed rotating hammers impacting materials, causing the materials to collide with the impact plates" for crushing. Although they have a large crushing ratio and good product particle shape, they have significant shortcomings as primary crushing equipment:

1. Sensitive to material hardness: More suitable for crushing medium to low hardness (compressive strength below 350MPa), brittle materials, such as limestone and dolomite. When processing hard, highly abrasive materials, the wear of the hammers and impact plates is very rapid, leading to a sharp increase in operating costs.

2. Feed Size Limitations: While large impact crushers can handle larger materials, their feed opening size is smaller than that of jaw crushers of the same size, placing higher demands on feeding equipment (such as heavy-duty feeders) to prevent material blockage.

3. Relatively Complex Structure and Weaker Impact Resistance: If uncrushable materials (such as iron blocks) are mixed in, they can easily cause serious damage to the rotor, hammers, and impact plates, posing a high risk.

Applicable Scenarios: Typically used as secondary or tertiary crushing (medium and fine crushing) equipment in production lines for aggregate shaping where strict particle shape requirements are met.

III. Selection Comparison Table

| Characteristics | Jaw Crusher | Impact Crusher |

| Crushing Principle | Compression, Grinding | Impact, Striking |

| Applicable Stage | Primary Crushing (Coarse Crushing) | Medium Crushing, Fine Crushing (Secondary/Third-Stage Crushing) |

| Applicable Material Hardness | High Hardness, High Abrasive Materials | Medium to Low Hardness, Brittle Materials |

| Feed Size | Very Large (Up to 1.5 meters or more) | Relatively Large, but usually smaller than a jaw crusher |

| Product Particle Shape | Average (High content of needle-like and flaky particles) | Excellent (Cubic shape, reasonable gradation) |

| Wear Parts Cost | Low (Good wear resistance of jaw plates) | High (Rapid wear of hammer plates, especially for hard materials) |

| Soil/Moisture Adaptability | Poor, prone to clogging | Good, with some anti-clogging ability |

Final Selection Recommendation

• When your raw material is hard granite, basalt, etc., and the blocks are very large, you should not hesitate to choose a jaw crusher as the primary crushing equipment.

• When your raw material is relatively soft limestone, and you highly value the final product's particle shape and are willing to bear higher costs for wear parts, you can consider using a large impact crusher for "single-stage crushing." However, this is a specific operating condition and not a universal solution.

• The most common high-efficiency configuration is a combination of a jaw crusher and an impact crusher: using a jaw crusher for primary crushing to break large pieces of material to medium size, followed by a strike-impact crusher for medium-fine crushing and shaping, balancing processing efficiency, operating costs, and product quality.