In today's rapidly developing environmentally friendly building materials and industrialized construction industry, Lightweight Expanded Clay Aggregate (LECA) has become a star material in the preparation of lightweight concrete, soil improvement, and wastewater treatment due to its excellent properties such as lightweight, high strength, thermal insulation, fire resistance, and corrosion resistance. The creation of high-quality LECA is inseparable from a core production system—the Lightweight Expanded Clay Aggregate Machine (also known as the LECA production line), which works perfectly with the ceramsite rotary kiln.

Today, we will delve into this key equipment, revealing how it transforms ordinary clay and shale into golden green building materials.

I. What is a Lightweight Expanded Clay Aggregate Machine? What role does it play in the ceramsite production line?

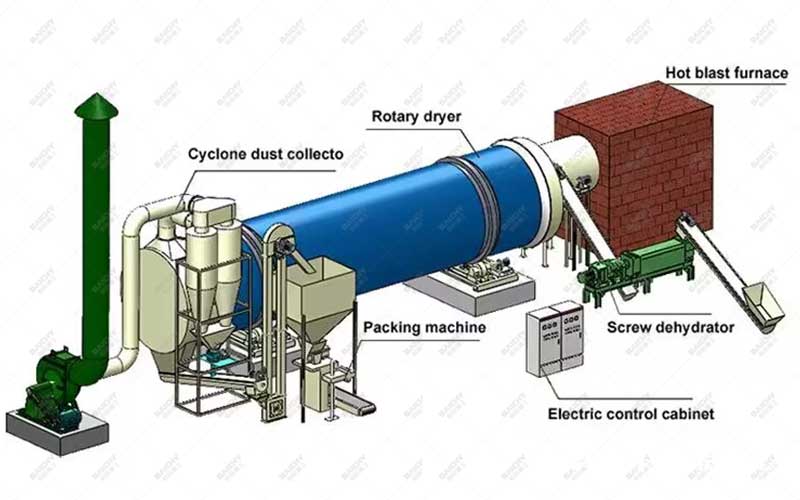

Simply put, the Lightweight Expanded Clay Aggregate Machine is an automated, continuous production line that provides qualified raw material pellets to the ceramsite rotary kiln and completes the sintering and expansion process. It is not a single machine, but a complete system encompassing multiple process stages including crushing, grinding, homogenization, granulation, preheating, sintering, and cooling.

In the entire expanded clay aggregate (LECA) production process, it is the crucial heart link, connecting upstream and downstream processes:

• Upstream: Processing raw materials (clay, shale, sludge, etc.) to achieve suitable fineness and composition.

• Downstream: Preparing uniformly sized and moderately strong raw material pellets for the rotary kiln, ensuring uniform heating and full expansion within the kiln, ultimately forming high-quality round or oval LECA particles.

It can be said that without a highly efficient and stable aggregate mill, the rotary kiln cannot achieve its optimal performance.

II. What are the core equipment components of a high-efficiency LECA production line?

A complete lightweight expanded clay aggregate production line typically includes the following core modules:

1. Raw material processing system: Including jaw crushers, roller mills, etc., used for initial crushing of large raw materials.

2. Grinding and homogenization system: Using Raymond mills, ball mills, etc., the raw materials are ground into fine powder, and then homogenized with water using a mixer to form a slurry with good plasticity.

3. Granulation and Molding System (Core): This is the most crucial part of the aggregate mill. Commonly used equipment includes twin-shaft mixers, extruders, and roller pelletizers. These systems use extrusion, cutting, or rolling to form uniformly sized spherical raw material pellets with a diameter between 5-25mm from the homogenized raw material.

4. Preheating and Sintering System: The raw material pellets first enter the preheating system before entering the rotary kiln to remove some moisture. Then, they enter the high-temperature ceramsite rotary kiln, where they rapidly expand at 1100-1200℃, melting and vitrifying the surface to form a porous, lightweight structure.

5. Cooling and Screening System: The sintered high-temperature ceramsite enters a cooler (such as a single-cylinder cooler) for rapid cooling to fix its microstructure. Finally, it is graded and packaged according to different particle sizes using a vibrating screen.

III. What are the core advantages of choosing a professional lightweight expanded clay aggregate mill?

Investing in a technologically advanced ceramsite production line means securing a leading market position. Its advantages are obvious:

• Superior Product Quality: Professional granulation technology ensures uniform raw material pellet size and high strength. Sintered LECA pellets are round, have high closed-cell rate, and high compressive strength.

• High Production Efficiency: Automated control system enables continuous production, high output, good stability, and effectively reduces energy consumption per unit product.

• Wide Raw Material Adaptability: Formulas and processes can be adjusted for different types of clay, shale, and even solid waste such as river silt and fly ash, achieving resource utilization.

• Economical Long-Term Operation: The equipment is rationally designed, wear-resistant, durable, and has a low failure rate, greatly reducing subsequent maintenance costs and downtime.

IV. Widely Used in Green Building and Environmental Protection Fields

LECA produced by the high-quality lightweight expanded clay aggregate machine is an ideal raw material for manufacturing the following products:

• Lightweight Concrete: Used to make lightweight blocks, insulation boards, etc., reducing the building's weight and improving thermal insulation performance.

• Building Backfill: Used for roof slope leveling and basement slab backfilling, offering advantages such as lightweight and excellent drainage.

• Soilless Cultivation: Serves as an excellent substrate, retaining water and fertilizer while providing good aeration.

• Water Treatment: Used as a biological filter media in wastewater treatment plants.

• Landscaping: Used for drainage layers and green paving.

To do a good job, one must first have the right tools. In the increasingly competitive expanded clay aggregate market, choosing a mature and stable lightweight expanded clay aggregate machine and expanded clay rotary kiln is crucial for ensuring product quality, controlling production costs, and gaining customer trust.

Baichy Heavy Industry has been deeply involved in the building materials machinery industry for decades. We provide not only single machines but also a one-stop solution for expanded clay aggregate production lines, encompassing raw material testing, process design, equipment manufacturing, installation and commissioning, and technical training. If you are planning to invest in a LECA project, please feel free to contact us for a customized solution and quote!