MTW mill for bentonite is an efficient and multifunctional grinding equipment, which is particularly suitable for the fine processing of bentonite. As an upgraded product of Raymond mill, MTW mill has significantly improved in production capacity, environmental protection, intelligence, and other aspects, and is an ideal choice for processing non-metallic minerals such as bentonite.

Advantages of MTW mill in bentonite processing

1. High efficiency: MTW mill can produce 3-55 tons per hour, which can meet the needs of bentonite processing enterprises of different sizes.

2. Adjustable fineness: By adjusting the parameters of the mill, bentonite fine powder with different fineness of 80-400 mesh can be produced to meet the requirements of bentonite fineness in different application fields.

3. Environmental protection and energy saving: The equipment adopts a unique air self-circulation system to effectively reduce dust emissions and meet modern environmental protection requirements. At the same time, the energy-saving design reduces energy consumption and improves economic benefits.

4. Intelligent operation: MTW mill is equipped with an advanced control system to realize intelligent operation, reduce labor costs, and improve production efficiency.

Bentonite processing flow

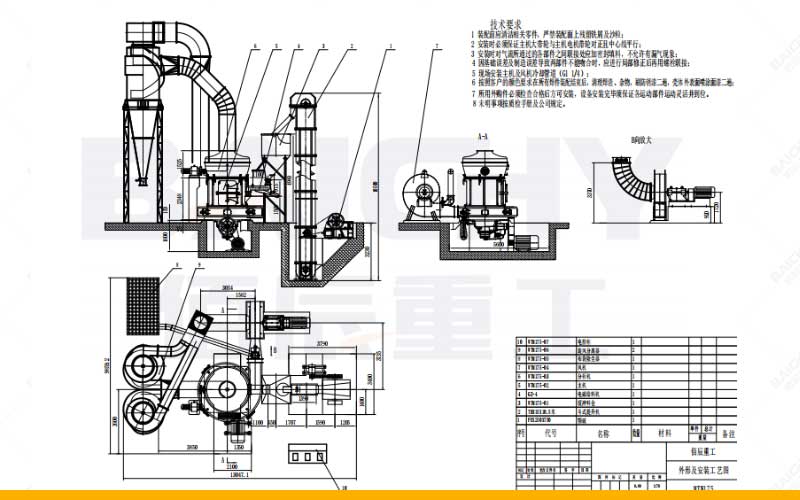

The bentonite processing flow generally includes the stages of socialization, drying, grinding, and classification:

• Sodiumization stage: The calcium-based bentonite is converted into sodium-based bentonite with better performance through sodiumization.

• Drying stage: The sodium-treated bentonite is dried at a low temperature to reduce the water content to ensure the smooth progress of subsequent processing.

• Grinding stage: The dried bentonite is crushed into a particle size that meets the requirements of the mill, and then lifted to the storage hopper by the elevator, and evenly fed to the MTW mill host by the electromagnetic vibrating feeder for grinding.

• Classification stage: The ground material is classified by the powder selector on the top of the host with the system airflow. The unqualified powder falls back into the grinding chamber of the host after classification for further grinding.

• Powder collection stage: The powder that meets the fineness enters the powder collection system with the airflow through the pipeline. After the air and powder are separated, the finished powder is sent to the finished product silo by the conveying device for packaging.

When using an MTW mill to process bentonite, the following points should be noted:

1. Regularly replace lubricating oil: The lubricating oil of the bentonite mill will gradually reduce its lubricating function during operation, so it is necessary to replace the lubricating oil regularly. The replacement frequency can be determined according to the equipment usage time and working environment.

2. Clean the lubricating system: Before replacing the lubricating oil, ensure that the lubricating system is clean to prevent impurities and dirt from entering the new lubricating oil and affecting its performance.

3. Pay attention to the quality of lubricating oil: Selecting high-quality lubricating oil is essential for the normal operation of bentonite mills. Lubricating oil with excellent high-temperature resistance, anti-oxidation, and anti-wear properties should be selected.

4. Prevent lubricating oil from deteriorating: Lubricating oil should be stored in a dry, ventilated, and light-proof place, away from high temperatures and open flame sources. Regularly check the acid value, viscosity, and cleanliness of the lubricating oil, and replace it in time if any abnormality is found.

MTW mill is a powerful assistant in the field of bentonite processing, which can produce high-quality bentonite fine powder products efficiently and environmentally friendly.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing onstone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.