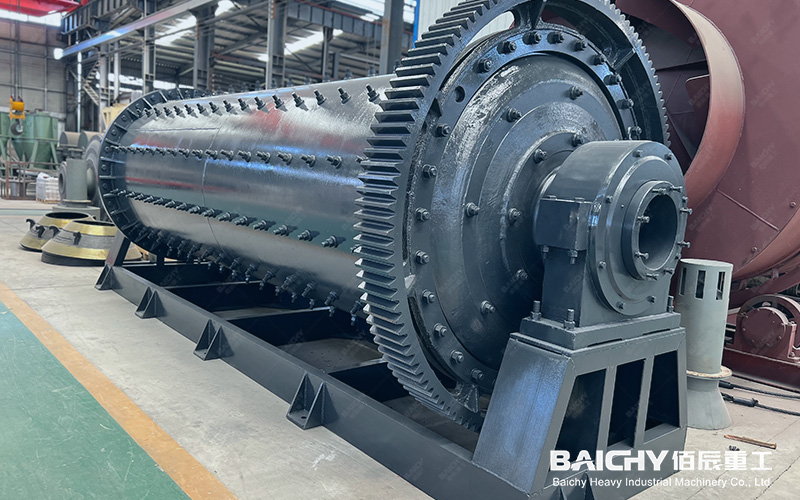

900x3000 ball mill

1200x2400 ball mill

Two Classic Models of Wet Ball Mills for Mining Applications

In the field of mineral processing, wet ball mills are indispensable core equipment for material grinding. Their model names typically directly reflect the key dimensions of the cylinder, for example, 900x3000 represents a cylinder with a diameter of 0.9 meters and a length of 3 meters, while 1200x2400 represents a diameter of 1.2 meters and a length of 2.4 meters.

As a manufacturer with 20 years of experience in mining equipment manufacturing, we understand the decisive impact of correctly selecting the model of mining ball mill on the efficiency, energy consumption, and final product particle size of the entire production line. This article will delve into the characteristics and application scenarios of these two classic wet ball mill models, providing professional guidance for your selection.

| Key Words | Selection Guide for 900x3000 and 1200x2400 Wet Ball Mills |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

In-depth Analysis of Model Differences: Performance Logic Behind Size Variations

900x3000 Wet Ball Mill: A Master of Fine Grinding and Small to Medium-Scale Processing

• Processing Capacity: This model is a medium-to-small ball mill, typically suitable for mining plants with a daily processing capacity of tens to hundreds of tons. Due to its slender cylinder characteristics, the material stays in the cylinder for a relatively longer time, which is conducive to more thorough grinding.

• Output Particle Size: The longer grinding path gives it a natural advantage in achieving finer product particle sizes, and it is often used in regrinding operations or small to medium-scale grinding of non-ferrous metals and non-metallic minerals where high product fineness is required.

• Energy Consumption and Footprint: The installed power is relatively small, the footprint is compact, and the investment and operating costs are low, making it suitable for projects with limited budgets or space constraints.

1200x2400 Wet Ball Mill: The Choice for Efficiency and Balance

• Processing Capacity: This model has a larger cylinder diameter and can accommodate more grinding media (steel balls), resulting in stronger impact force. Therefore, its single-unit processing capacity is significantly higher than the 900x3000 model, making it suitable for operations with a daily processing capacity of hundreds to several hundred tons.

• Grinding Efficiency: The short and thick cylinder shape allows for faster material flow, resulting in higher grinding efficiency. While ensuring a certain degree of fineness, it prioritizes maximizing processing capacity. Commonly used for coarse grinding or primary grinding operations in metal mines such as iron ore and copper ore.

• Applicability: Under the same processing capacity requirements, choosing one 1200x2400 ball mill may be more cost-effective than using multiple smaller units, making it the preferred balanced solution for medium-sized beneficiation plants.

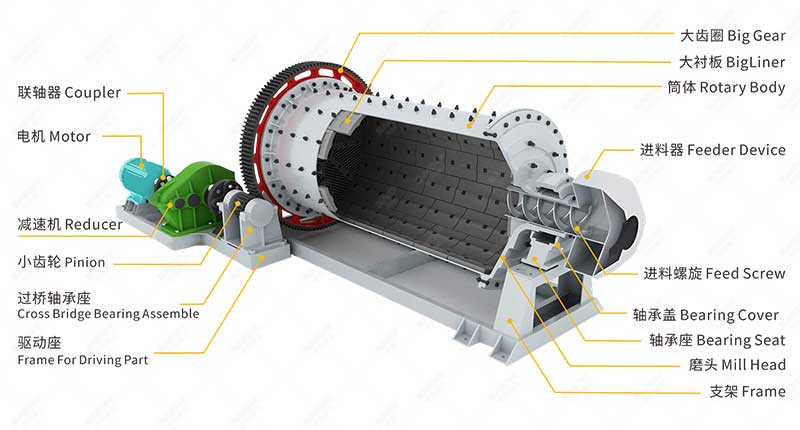

Ball mill structure diagram

Our Core Advantages: Twenty Years of Dedicated Manufacturing

With twenty years of technological accumulation, our mining grinding ball mills possess the following outstanding advantages:

1. Optimized Structure: The cylinder is made of high-quality steel plate, ensuring high strength and stable operation. The scientifically designed feed and discharge ends ensure smooth material flow.

2. Wear Resistance Guarantee: The liners and grinding media are cast from multi-element alloy steel, offering high hardness and toughness. Their wear resistance is several times that of ordinary materials, significantly reducing maintenance costs.

3. Reliable Transmission: Utilizing large double-row self-aligning roller bearings or traditional sliding bearings (depending on the configuration), coupled with flexible transmission, ensures easy starting, low operating energy consumption, and low noise.

4. Process Adaptation: We not only provide equipment but also recommend the most suitable model (900x3000 or 1200x2400, etc.) and configure the optimal installed power, speed, and grinding media grading based on your ore properties (hardness, particle size, density) and process objectives.

Case Studies

• Case Study 1 (900x3000): A fluorite mine beneficiation plant in Hunan Province, China, required a final grinding fineness of 90% passing -200 mesh after coarse crushing. We recommended and provided a 900x3000 wet-type grid ball mill for the regrinding stage, which consistently met the fineness requirements, and the power consumption was 15% lower than the client's expectations.

• Case Study 2 (1200x2400): A medium-sized copper mine project in Peru, processing 500 tons of raw ore per day. We configured a 1200x2400 wet overflow type ball mill as the primary grinding equipment, with a stable processing capacity of 22-25 tons/hour. This provides qualified pulp for subsequent flotation operations. The equipment has been running for two years without major repairs.

Related Equipment Recommendations

A complete grinding production line requires not only the core ball mill but also supporting equipment to create a synergistic effect:

• Feeding equipment: Trough feeders and belt conveyors to ensure uniform and stable feeding.

• Classification equipment: Spiral classifiers or hydrocyclones, forming a closed-circuit system with the ball mill to improve grinding efficiency.

• Auxiliary equipment: Slurry pumps (for transporting pulp), electric hoists (for equipment maintenance).

Frequently Asked Questions (FAQ)

Q1: Which has a larger output, the 900x3000 or the 1200x2400 ball mill?

Generally, the 1200x2400 ball mill has a larger processing capacity. Because of its larger diameter, it can accommodate more grinding balls, resulting in stronger impact and grinding capabilities. However, the specific output also depends on the grindability of the ore, the feed particle size, and the required product fineness.

Q2: What are the advantages of a wet ball mill compared to a dry ball mill?

Wet ball mills add water during grinding, effectively reducing material temperature and dust pollution, making them more suitable for subsequent wet beneficiation processes (such as flotation). They also have lower noise levels, and for the same size, wet grinding is usually more efficient and produces less over-grinding than dry grinding.

Q3: How long does equipment delivery and installation/commissioning take?

For standard models like the 900x3000 and 1200x2400, our regular delivery time is 30-45 days. We provide complete foundation drawings, a list of wear parts, and detailed installation manuals, and can dispatch engineers to guide installation and commissioning to ensure rapid equipment commissioning.

Choosing between the 900x3000 and 1200x2400 wet ball mill is essentially a comprehensive decision based on your processing scale, product fineness, and investment budget. There is no absolute best or worst option, only what is suitable. We recommend that you provide detailed ore samples and processing requirements, and our engineers will provide you with a customized mineral processing equipment solution.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.