Raymond Roller Mill, although usually designed to produce medium to fine powder products, can also be used to obtain relatively coarse powders in some cases by adjusting its operating parameters. Here are some ways to achieve this goal:

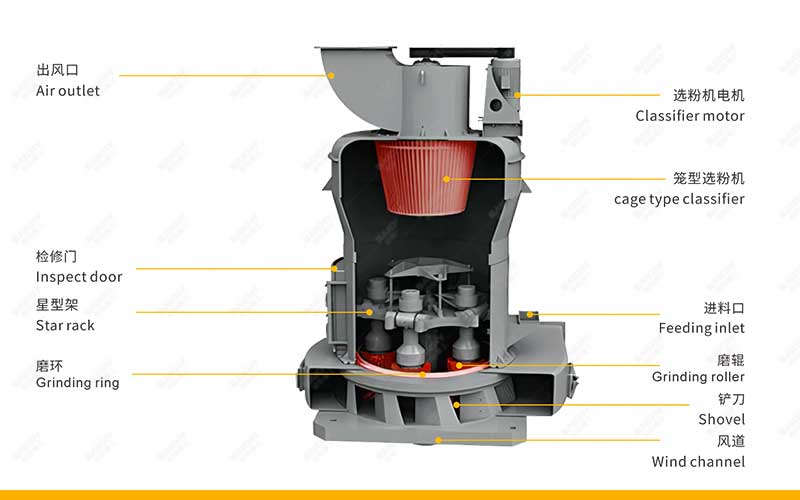

Adjust the classification system: Raymond Roller Mill is usually equipped with a classification system (such as a cyclone separator or bag filter) to separate the ground material by particle size. To obtain a coarse powder, the parameters of the classification system can be adjusted, such as reducing the speed of the classifier or adjusting its internal structure to reduce the separation efficiency of fine powder, so that more coarse particles can pass through and be collected.

Control grinding pressure and time: Reducing the grinding pressure of the grinding roller on the material or shortening the residence time of the material in the mill can reduce the degree of grinding of the material, thereby producing a coarser powder. This can be achieved by adjusting the pressing device of the grinding roller, changing the feed rate, or adjusting the speed of the grinding roller.

Choosing the right grinding media: Although the grinding media (i.e., rollers and rings) of a Raymond roller mill are usually fixed, in some cases, the grinding effect can be affected by changing or adjusting the material, shape, or surface roughness of the rollers and rings. However, such adjustments are usually limited and need to be considered in the overall design and manufacturing requirements of the equipment.

Pretreatment of materials: Pretreatment of materials before entering the Raymond roller mill (such as coarse crushing, screening, etc.) can reduce the particle size range of materials entering the mill, making it easier to control the particle size of the final product.

It should be noted that although the Raymond roller mill can be adjusted to produce coarse powder by the above methods, its original design and optimization direction are still for the production of fine powder. Therefore, when trying to produce coarse powder, it may be necessary to weigh multiple factors such as output, particle size distribution, energy consumption, and equipment wear, and conduct multiple tests to find the best operating parameters.

In addition, if the demand for producing coarse powder is large or the requirements are high, it may be necessary to consider using other grinding equipment that is more suitable for producing coarse powder, such as ball mills, hammer crushers, etc.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing onstone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.