VSI sand making machine, namely vertical shaft impact crusher, is an efficient and versatile stone processing equipment, which is widely used in construction, highways, high-speed railways, high-rise buildings, hydropower dam construction and concrete mixing stations, providing high-quality sand and gravel aggregates.

Working principle of VSI sand making machine

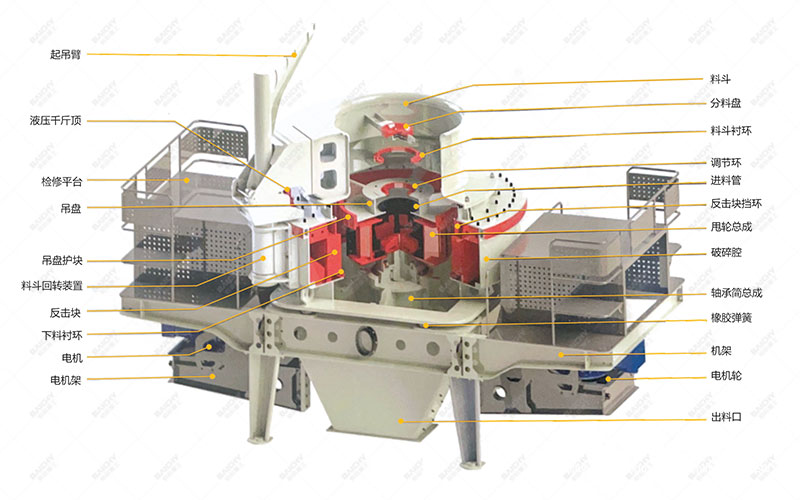

VSI sand making machine adopts advanced "stone hitting stone" crushing principle and technology. During the crushing process, the material is thrown into the crushing chamber by the high-speed rotating rotor, and is crushed by impact and friction with the material lining or other materials. This crushing method not only realizes the fine crushing of stones, but also completes the sand making product, and has the shaping function to make the sand and gravel particles regular to meet various engineering needs.

Performance characteristics of VSI sand making machine

1. Large processing capacity: VSI sand making machine has a wide range of production capacity, usually between 60~650t/h, which can meet the production needs of different scales.

2. Uniform product particle size: By adjusting parameters such as rotor speed and feed particle size, the particle size of the product can be flexibly controlled to ensure uniform and reasonable sand and gravel particle size.

3. Long life of wear-resistant parts: The wear-resistant parts are made of high wear-resistant alloy materials, and the service life is more than 6 to 8 times higher than that of high manganese steel, which reduces the replacement frequency and maintenance cost.

4. High safety performance: The equipment is reasonably designed and adopts a closed structure to reduce dust pollution and noise pollution. At the same time, it is equipped with safety protection devices to ensure the safety of operators.

5. Easy maintenance: The equipment has a compact structure and is easy to maintain. The hydraulic cover opening device makes the inspection and replacement of the crushing internal parts convenient and quick, shortening the downtime.

Applicable materials of VSI sand making machine

VSI sand making machine is widely used in medium and fine crushing of various hard and brittle materials such as various rocks, abrasives, refractory materials, cement clinker, etc. Specifically, it can process pebbles, river pebbles, limestone, bluestone, granite, basalt, diopside, andesite.

Application advantages of VSI sand making machine

1. Low investment cost: Compared with traditional process equipment of the same scale, the investment cost of VSI sand making machine is reduced by 35% to 50%.

2. High output efficiency: Taking limestone as an example, the proportion of finished products with a particle size of ≤5mm can reach more than 90%; for river pebbles, the proportion of finished products with a particle size of ≤5mm can also reach more than 80%. Overall, the output efficiency of VSI sand making machine has increased by 35% to 50%.

3. Low operation and maintenance costs: The long-term operation and maintenance costs of VSI sand making machine are also low, reducing by about 35% to 50%.

Precautions for using VSI sand making machine

1. Feed particle size control: The material must be fed in accordance with the particle size specified in the technical performance parameter table of the machine. It is strictly forbidden to feed materials with a particle size exceeding the specified size.

2. Water content control: The maximum water content of the crusher should be controlled below 20%. Usually, the ore treated by the sand washer can be directly fed into the crusher for crushing.

3. Regular maintenance: Regularly maintain and service the equipment to ensure the normal operation of the equipment and extend its service life.

VSI sand making machine plays an important role in the field of construction sand and gravel production with its advantages of high efficiency, energy saving, environmental protection and safety.