Hammer crusher is a kind of equipment that crushes materials in the form of impact. It can directly crush materials with a maximum particle size of 600~1800 mm to less than 25 mm.

PC400×300 hammer crusher is suitable for medium and fine crushing of various soft and hard ores with a compressive strength not higher than 100MPa, such as limestone, slag, coke, coal and other materials. At the same time, it can also be used to crush materials such as construction waste, marble, bluestone, etc.

PC400x300 hammer crusher technical parameters

Rotor diameter: 400mm

Rotor length: 300mm

Rotor speed: usually 1100r/min (but may vary by manufacturer and specific model)

Maximum feed size: <100mm

Discharge size: 5~15mm (adjustable)

Processing capacity: 5-10t/h (depending on factors such as material hardness and humidity)

Motor power: 11Kw

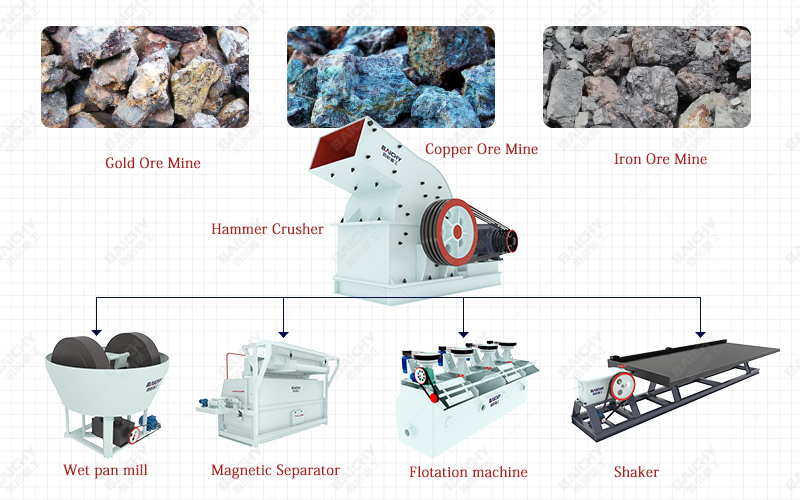

CIP beneficiation production line is an efficient and environmentally friendly gold ore beneficiation technology. It dissolves the gold in the gold ore in a cyanide solution and then uses activated carbon to adsorb gold ions to achieve gold extraction. This production line has the advantages of high efficiency, low consumption and environmental protection, and is one of the important methods of modern gold ore beneficiation.

Crushing and grinding: The gold ore is first crushed by hammer crushing, and then finely crushed and ground by a grinding machine (such as a ball mill) to make the ore particles reach a particle size suitable for leaching. Usually, the particle size range of -200 mesh accounts for more than 70%.

After grinding, the ore needs to be classified to remove the ore particles that do not meet the particle size requirements. The classification equipment usually uses a spiral classifier or a hydrocyclone.