Coal mill is a machine that crushes coal blocks and grinds them into pulverized coal. It is an important auxiliary equipment for pulverized coal furnaces. Coal mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and non-ferrous metal mineral processing, glass and ceramics and other production industries to dry or wet grind various ores and other grindable materials. grind.

The working principle of the coal mill mainly includes four stages: crushing, grinding, classification, and powder collection. In the crushing step, the raw ore is crushed by the crusher, and the material enters the grinding roller channel and is continuously squeezed, ground, cut, and crushed under the pressure of the grinding roller. The high-speed airflow at the air outlet will blow up the ground materials, and the coarser materials will be blown back to the grinding disc for re-grinding. At the same time, the suspended materials can be dried, the fine powder enters the classifier for classification, and the qualified powder is collected by the collector to become a finished products.

Can vertical roller mills and ball mills be used to grind coal?

Both vertical roller mills and ball mills can be used to grind coal.

How does a Vertical roller mills for coal work?

Vertical roller mill has certain advantages in the deep processing of coal. It adopts a unique production process and structure, occupies a small area, has less dust and low noise during the production process, and the pulverized coal produced has efficient gradation and excellent combustion performance. In addition, the vertical grinding mill consumes less power for grinding and can adapt to raw coal with high moisture content, so there is no need to add auxiliary machines. The vertical mill also integrates the five processes of crushing, grinding, drying, powder selection, and transportation, with a simple process and compact layout.

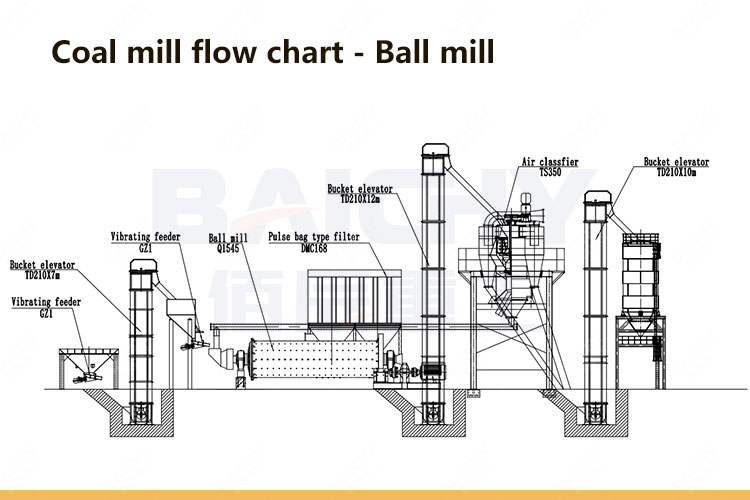

How does a Ball mills for coal work?

Ball mills are also suitable for grinding various ores and other materials, including coal. It can be used for dry or wet grinding, the particle size of the finished product can be adjusted freely, and the particle shape is uniform. The working principle of the ball mill is to generate centrifugal force through the rotation of the cylinder, which will bring the steel balls to a certain height and then fall, which will pound and grind the materials.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.