What are forged grinding steel balls?

Forged grinding steel balls are a type of grinding media produced through a forging process. During the manufacturing process, the metal blank is heated to a certain temperature (usually between 700-1300°C), and then a forging machine is used to apply pressure to it to cause plastic deformation to obtain the required shape and size.

Forged grinding steel balls usually have excellent mechanical properties, such as high hardness, high wear resistance, good impact resistance, and toughness. These properties make them ideal for processes such as grinding, crushing, and mixing.

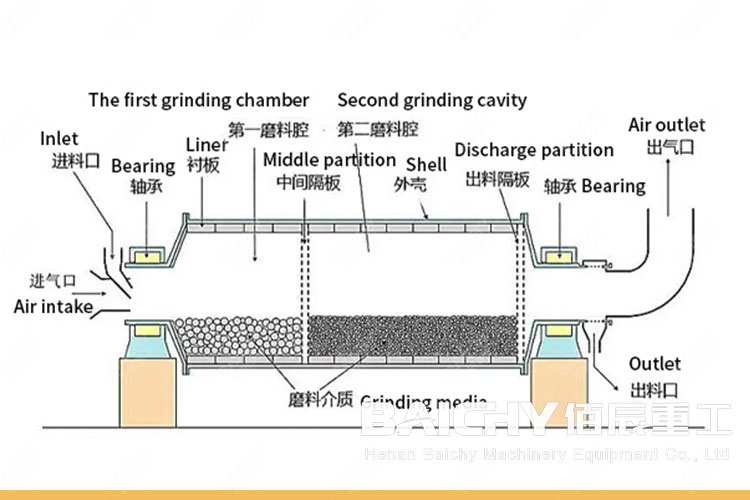

Forged grinding steel balls are widely used in various industrial fields, such as mining, electric power, cement, ceramics, chemical industry, etc. In the mining industry, they are often used in ball mills for grinding ores; in the power industry, they are often used in coal mills in thermal power plants; in the cement and ceramics industries, forged grinding steel balls are also used for material grinding. Grind and mix.

Advantages of forged grinding steel balls

Compared with steel balls produced by other manufacturing processes, forged grinding steel balls have the following significant advantages:

• High wear resistance: The forging process can refine the grains inside the steel ball and make the structure denser, thereby improving the hardness and wear resistance of the steel ball. This allows the forged grinding steel balls to maintain better shape and performance during long-term grinding processes and extend their service life.

• High impact resistance: During the forging process, the steel ball will undergo plastic deformation when subjected to external force, thereby absorbing impact energy. This characteristic makes the forged grinding steel balls have better impact resistance and are not easily broken under high-speed impact and heavy-load grinding conditions.

• Good toughness: The forging process can generate a certain amount of residual stress inside the steel ball, which helps to improve the toughness of the steel ball. Steel balls with good toughness are less likely to crack and break when subjected to impact and extrusion, which improves the safety of steel balls.

• High precision and stability: The forging process can control the size and shape accuracy of the steel ball, ensuring that the steel ball can be evenly stressed during the grinding process and improving grinding efficiency. In addition, the forged grinding steel balls have good dimensional and shape stability, which can reduce fluctuations in grinding quality caused by uneven wear of the steel balls.

• Good adaptability: Forged grinding steel balls can be customized and produced according to different grinding processes and material characteristics to adapt to different grinding needs. For example, the hardness, wear resistance, and other properties of the steel ball can be changed by adjusting the alloy composition, heat treatment process, and other methods to meet the use requirements under specific grinding conditions.

• Environmental protection and energy saving: The forged grinding steel balls have little wear and a low breakage rate during use, which reduces the number of frequent replacements of steel balls and cleaning of grinding equipment, reducing production costs and energy consumption. At the same time, the forging process itself also has high energy utilization efficiency and material utilization rate, which is in line with the development trend of environmental protection and energy saving.