Granite crushing production line usually consists of a vibrating feeder, jaw crusher (primary crushing), cone crusher (secondary crushing), sand making machine (third-stage crushing), vibrating screen, conveyor belt, and other equipment. Through reasonable configuration and layout, efficient, continuous, and automated crushing operations can be achieved.

Among the coarse granite crushing equipment, jaw crusher is a common and efficient choice; a jaw crusher can handle large pieces of granite and achieve efficient coarse crushing operation. A jaw crusher usually has an adjustable crushing chamber, and the outlet size of the crushing chamber can be adjusted as needed to control the particle size of the crushed product.

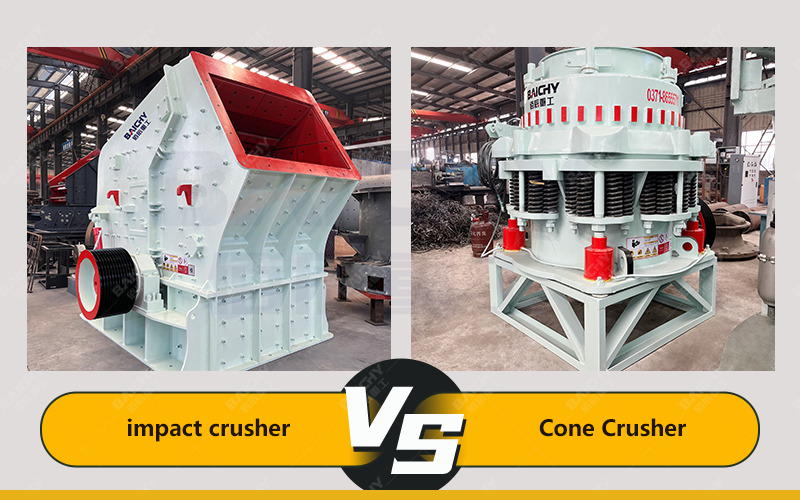

Among the medium granite crushing equipment, impact crusher and cone crusher are two common choices.

Impact crusher uses impact energy to crush materials. After entering the crushing chamber, the material is crushed by the impact of the high-speed rotating plate hammer, and the crushed material is impacted to the liner for crushing again, and finally discharged through the screen plate.

Cone crusher consists of a conical crushing chamber and a rotating crushing cone. The material enters from the feed port of the crushing chamber, is crushed by the squeezing and rolling action of the crushing cone, and the crushed material is discharged from the bottom of the crushing chamber.

When choosing medium-crushing granite crushing equipment, comprehensive consideration should be given to factors such as production requirements, material characteristics, and investment budget. The impact crusher is suitable for medium-hard materials with high crushing efficiency requirements and uniform product particle size requirements; the cone crusher is suitable for medium-fine crushing operations with large crushing ratios and the need to adjust the discharge particle size.

VSI sand making machine (vertical shaft impact crusher) performs well in fine crushing of granite. Its unique working principle and superior performance characteristics make it an important equipment in this field.

VSI sand making machine is widely used in the fine crushing of hard rocks such as granite. VSI sand making machine uses a high-speed rotating rotor to crush materials by impact and grinding. During the crushing process, the material first enters the crushing chamber, is crushed by the impact of the high-speed rotating rotor, and then undergoes multiple impacts, friction, and grinding in the crushing chamber to eventually form fine particles. VSI sand making machine can adjust the rotor speed and the structure of the crushing chamber according to the needs to achieve the ideal fine crushing effect.