In the mining crushing industry, granite has always been considered a "tough nut to crack." Its high hardness and wear resistance not only guarantee high-quality aggregates but also pose the ultimate test for crushing equipment. Choosing an unsuitable granite crusher means high costs for wear parts, frequent downtime for maintenance, and low production efficiency. So, how do you tailor the most effective crushing solution for this "tough nut to crack"? This article will serve as your professional guide, providing an in-depth analysis of the world of granite crushers, from core principles to equipment selection.

I. Why is granite a formidable challenge for crushers?

Know yourself and know your enemy, and you will never be defeated. Before understanding the equipment, we must first understand our "opponent"—granite.

• High Hardness and High Strength: Granite typically has a Mohs hardness of 6-7 and a compressive strength exceeding 200 MPa. This means that crushing equipment needs to apply enormous force to break it.

• High silica content and strong abrasiveness: Quartz minerals in granite are "equipment killers," causing extremely severe wear on the vulnerable parts of the crusher (such as jaw plates, hammers, and grinding bowls).

• Strict finished product requirements: The final crushed aggregate needs to have good particle shape (cubic, needle-free flaky) and reasonable gradation to meet the stringent standards of high-grade highways, construction, and water conservancy projects.

These characteristics determine that not all crushers are suitable for processing granite. High efficiency, wear resistance, and stability are the core keywords for granite crushers.

II. Mainstream types of granite crushers and their working principles

Due to the characteristics of granite, the market has developed a technical route based on "compression crushing" as the main method and "impact crushing" as a supplement. A typical granite crushing production line is often the result of multiple pieces of equipment working together.

1. Jaw Crusher - The "Iron Fist Vanguard" in the coarse crushing stage

• Working principle: Employs the compression crushing principle that simulates the chewing motion of animals using two jaw plates. The moving jaw reciprocates periodically relative to the fixed jaw, crushing the material located between the two jaw plates.

• Applicable Scenarios: The first stage of a granite crushing production line – coarse crushing. Its large feed opening easily handles large raw stones with a diameter exceeding 1 meter.

• Advantages: Simple structure, robust and durable, easy maintenance, and large processing capacity, making it the most economical and reliable choice for the coarse crushing stage.

• Disadvantages: Poor finished particle shape, with a high content of needle-like and flaky particles; usually requires use in conjunction with medium crushing equipment.

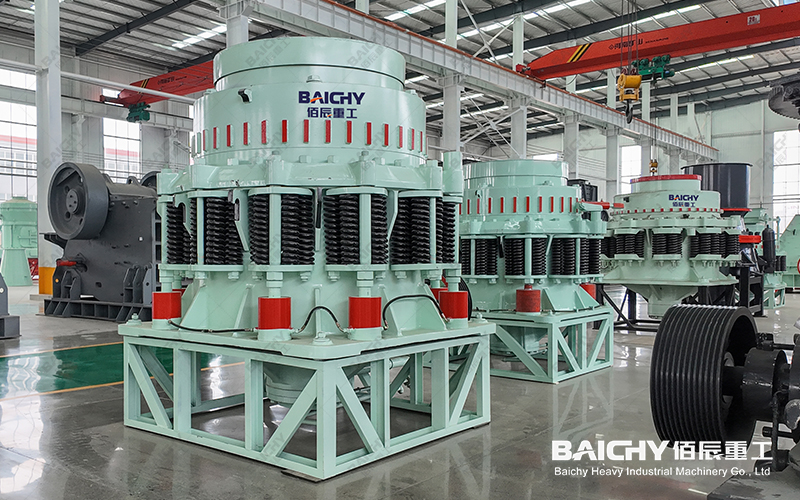

2. Cone Crusher – The "Backbone" of Medium and Fine Crushing Stages

• Working Principle: Employs the principle of layered crushing. The moving cone rotates eccentrically within the fixed cone, and the material is continuously squeezed and bent between them, resulting in crushing. This is the preferred and mainstay for processing granite.

• Applicable Scenarios: Medium and fine crushing stages in a production line. Receives coarse material from a jaw crusher and crushes it to a smaller particle size.

• Advantages:

◦ High wear resistance: Layered crushing distributes wear more between materials, reducing direct wear on vulnerable parts and extending service life.

◦ Stable operation: High production capacity, relatively low energy consumption, suitable for large-scale continuous production.

◦ Good finished product quality: Particle shape is better than jaw crushers, but slightly inferior to impact crushers.

• Classification: Can be pided into spring cone crushers, hydraulic cone crushers (single-cylinder, multi-cylinder), etc. Hydraulic cone crushers have advantages in automation and clearing function.

3. Impact Crusher (Sand Making Machine) - The "Master of Shaping and Sand Making"

• Working principle: Employs the "stone-on-stone" or "stone-on-iron" impact crushing principle. Material is accelerated by the high-speed rotating impeller and thrown out, violently impacting the material lining or anvil in the crushing chamber for crushing.

• Applicable scenarios: Fine crushing, ultrafine crushing (sand making), and aggregate shaping stages in production lines.

• Advantages:

◦ Excellent particle shape: The produced sand and gravel aggregates are mostly cubic with a reasonable gradation, making them ideal raw materials for high-performance concrete.

◦ High efficiency: Large crushing ratio and significant fine crushing effect.

• Disadvantages:

◦ Rapid wear of wear-resistant parts: Direct impact causes very rapid wear on components such as the hammer and throwing head when processing high-silica granite, resulting in higher operating costs.

◦ More powdery material: Impact crushing produces a lot of stone powder, requiring the use of dust removal equipment.

III. How to configure an efficient granite crushing production line for you?

There is no best equipment, only the most suitable solution. A scientific granite crushing production line usually follows the "multi-stage crushing" principle and fully considers the balance between investment and operating costs.

• Classic two-stage crushing process: Jaw crusher (coarse crushing) + Cone crusher (medium and fine crushing). This is the most robust and common configuration, suitable for markets that primarily produce crushed stone of different sizes.

• Three-stage crushing process: Jaw crusher (coarse crushing) + Cone crusher (medium crushing) + Impact crusher (sand making and shaping). This solution produces high-value-added, high-quality manufactured sand while producing crushed stone, maximizing resource value.

• Mobile crushing plant: For projects with dispersed mining areas requiring relocation, a mobile crushing plant integrating feeding, crushing, and conveying provides extremely high flexibility, significantly reducing infrastructure and transportation costs.

Key considerations for selection:

1. Capacity requirements: What is your expected hourly or annual output?

2. Feed size: What is the maximum particle size of the raw stone?

3. Finished product specifications: What particle sizes of finished products do you need (e.g., 0-5mm, 5-10mm, 10-20mm)? What are the respective proportions?

4. Investment budget: What is your equipment purchase budget and long-term operating cost budget?

Granite crushing is a systematic project; choosing the right crusher is crucial to determining the return on investment. Jaw crushers, cone crushers, and impact crushers each perform their specific functions, working together to form a powerful tool for conquering granite. As seasoned industry participants, we understand that a high-quality, highly adaptable granite crusher is not only a production tool, but also a core competitive advantage for winning in the market.