In today's booming infrastructure construction, granite, as a high-quality building stone known for its high hardness, compressive strength, and corrosion resistance, continues to be in high demand. A scientifically designed and rationally configured granite crushing production line is the core guarantee for quarries to maximize their economic benefits. This article will focus on the mainstream medium-sized production capacity of 100-120 tons per hour, deeply analyzing its core components, process flow, equipment selection, and investment value, providing detailed reference for your project planning.

I. Why Choose 100-120 Tons/Hour?

A production line with a capacity of 100-120 tons per hour represents the golden capacity range in the current market. It can meet the stable material supply needs of small and medium-sized engineering projects, commercial concrete plants, and highway base construction without placing a heavy burden on owners due to excessive investment or overcapacity. This capacity scale achieves the best balance between equipment investment, energy consumption control, site occupation, and operation management, resulting in a considerable return on investment, making it very suitable for investors intending to enter or expand the sand and gravel business.

II. Core Process Flow Analysis: Layered Crushing, Precise Screening

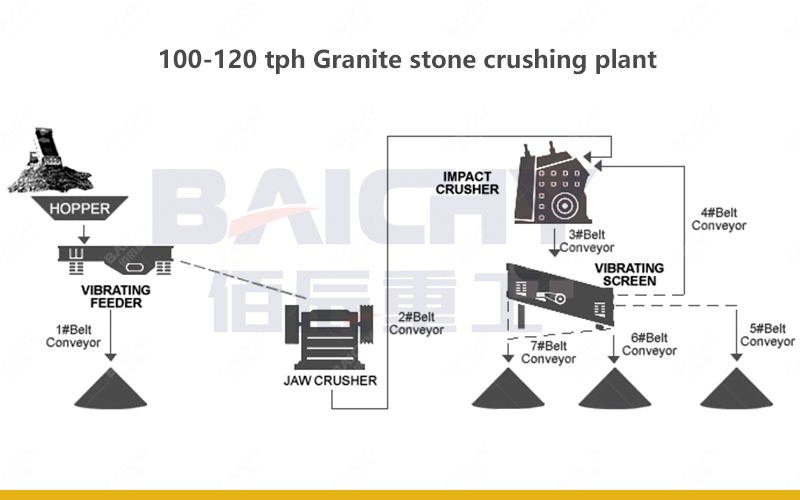

A high-efficiency granite crushing production line is not simply a collection of equipment, but a sophisticated design based on the principle of more crushing, less grinding, and graded processing. A typical process flow includes stages such as feeding coarse crushing medium crushing screening fine crushing finished product screening.

1. Feeding Stage: Handled by a vibrating feeder, this stage uniformly and continuously feeds the raw granite material, whether blasted or loaded by an excavator, into the coarse crushing equipment. It is the first line of defense ensuring the stable operation of subsequent processes.

2. Coarse Crushing Stage (Jaw Crusher): This is the first line of defense against the extremely hard granite. With its powerful crushing force and high reliability, the jaw crusher undertakes the crucial task of crushing large pieces of granite (typically with a feed size ≤750mm) to a medium particle size of approximately 150mm. Its V-shaped crushing chamber design ensures high crushing efficiency.

3. Intermediate Crushing Stage (Cone Crusher): The coarsely crushed material is fed into the cone crusher via a belt conveyor. The cone crusher uses a layered crushing principle and is particularly suitable for processing hard materials like granite, further crushing them to approximately 40-60mm. Its performance directly determines the overall efficiency of the production line and the content of needle-like and flaky particles in the finished product.

4. Screening Stage (Vibrating Screen): The vibrating screen is the command center of the production line. It classifies the material after intermediate crushing. Material meeting specifications is directly screened out, while oversized material is sent back to the next process. This step is crucial for achieving accurate material classification and ensuring a high product qualification rate.

5. Fine Crushing and Shaping Stage (Impact Crusher/Sand Making Machine): If high-quality manufactured sand is required or higher requirements are placed on the stone particle shape, an impact crusher (sand making machine) is usually introduced. It utilizes the stone-on-stone or stone-on-iron principle to shape and finely crush the material, effectively improving particle shape, reducing needle-like and flaky content, and producing well-graded manufactured sand. III. Key Equipment Selection Recommendations: Stability and Efficiency Go Hand in Hand

Given the high hardness of granite, equipment selection must prioritize wear resistance and stability.

• Coarse Crushing Equipment: A deep-cavity jaw crusher is the first choice. The moving jaw should be made of high-strength manganese steel to ensure impact resistance and wear resistance.

• Medium and Fine Crushing Equipment: Cone crushers are the absolute mainstay. Hydraulic cone crushers are recommended, as they feature convenient cavity clearing, overload protection, and automatic discharge port adjustment, significantly reducing downtime and simplifying maintenance.

• Sand Making Equipment: Choose an impact crusher with reversible side guards and an optimized crushing chamber design to reduce wear component costs.

• Auxiliary Equipment: Vibrating feeders, vibrating screens, belt conveyors (bandwidth and speed must be matched to output), and centralized electrical control systems are also crucial. A reliable electrical control system enables one-button start/stop and interlocking control, greatly improving operational safety and efficiency.

IV. Production Line Advantages and Investment Value

A well-designed granite crushing production line with a capacity of 100-120 tons per hour possesses the following outstanding advantages:

• High Efficiency and High Output: A compact process and reasonable crushing ratio ensure stable production capacity.

• Excellent Finished Products: Multi-stage screening combined with shaping and crushing results in rounded aggregate particles with continuous gradation, giving it strong market competitiveness.

• Energy Saving and Environmental Protection: Dry dust removal or a spray system can be used to effectively control dust; the equipment's energy consumption is continuously optimized, meeting green production standards.

• Quick Return on Investment: Stable equipment operation, low failure rate, and controllable maintenance costs allow for a rapid recovery of investment and profitability.

In conclusion, constructing a granite crushing production line with a capacity of 100-120 tons per hour is a systematic project requiring comprehensive consideration of material characteristics, capacity requirements, finished product specifications, and investment budget. Choosing an experienced equipment supplier and a scientifically sound process design is the cornerstone of successful project commissioning and long-term value creation. We hope this article provides strong technical support for your decision-making.