In mining, building materials, and large-scale infrastructure projects, crushing hard rock (such as granite, basalt, and quartz) has always been a key challenge in terms of production efficiency and cost control. Faced with materials of high hardness and high abrasiveness, a scientifically designed and well-configured crushing production line is the cornerstone of ensuring project profitability. This article will delve into a 150-ton-per-hour hard rock crushing production line, particularly the heart role of the jaw crusher, revealing the core secrets to efficient and stable production.

I. Challenges and Core Requirements of Hard Rock Crushing

Hard rock is not easy to handle. Its high compressive strength and strong abrasiveness pose severe challenges to crushing equipment:

• High wear resistance requirements: Wear parts (such as jaw plates and hammers) must be made of ultra-high wear-resistant materials to extend service life and reduce downtime for replacements and spare parts costs.

• High structural strength requirements: The main frame of the equipment must be robust and reliable to withstand continuous high-intensity impact loads and avoid structural fatigue damage.

• High-efficiency crushing requirements: The production line process design must be reasonable, maximizing crushing efficiency and reducing energy consumption per ton of output while ensuring the output particle shape and gradation.

A target of 150 tons per hour means the production line must have continuous, stable, and efficient processing capabilities. Any weakness in any link could lead to insufficient capacity and a surge in operating costs.

II. Core of the Production Line: The Stabilizing Role of the Jaw Crusher

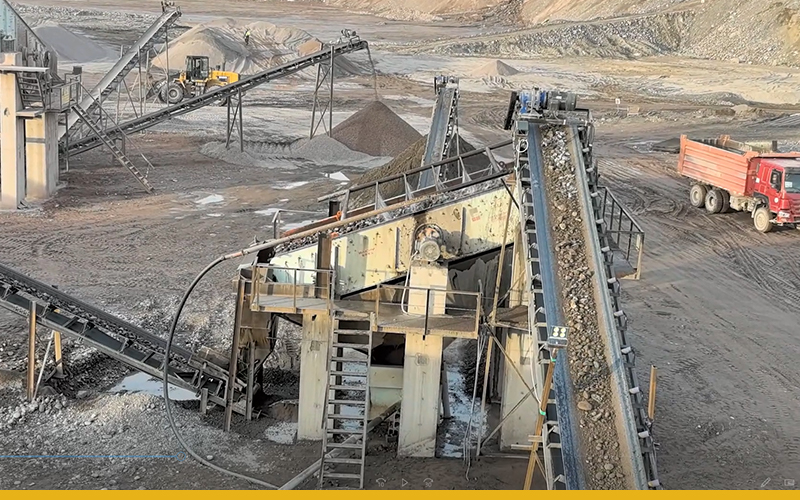

In a 150-ton/hour hard rock crushing production line, the jaw crusher undoubtedly plays the crucial role of primary crushing, being the first and most critical step.

1. Powerful primary crushing capacity: With its unique V-shaped crushing chamber and enormous compressive force, the jaw crusher can easily swallow large raw hard rocks with particle sizes reaching hundreds or even thousands of millimeters, achieving initial size reduction. Its powerful motor and robust structure provide reliable protection against the impact of hard rocks.

2. Laying the foundation for subsequent processes: After coarse crushing by the jaw crusher, the material becomes relatively uniform in particle size, creating ideal feeding conditions for subsequent medium crushing (such as cone crushers) or fine crushing (such as impact crushers) equipment. This effectively reduces the burden on subsequent equipment and improves the overall efficiency and stability of the production line.

3. High reliability and ease of maintenance: The jaw crusher has a simple structure, reliable working principle, and low failure rate. The replacement of its core wear component—the jaw plate—is relatively simple, greatly reducing maintenance time and labor costs, and ensuring continuous operation of the production line.

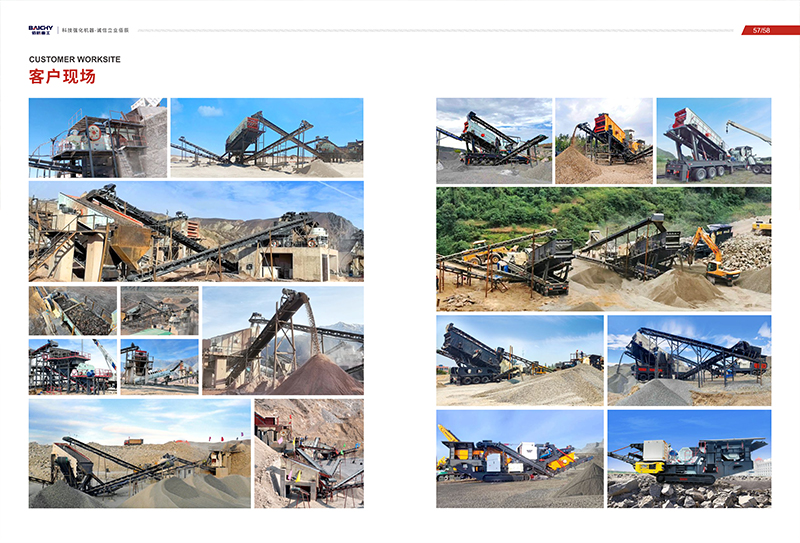

III. Typical Configuration Scheme for a 150-ton/hour Hard Stone Crushing Production Line

A complete production line involves far more than just one jaw crusher. It is a collaborative system engineering project, typically including:

• Feeding system: A vibrating feeder, responsible for uniformly and continuously feeding the raw material from the hopper into the jaw crusher, avoiding stalling or idling.

• Coarse Crushing System: Heavy-duty jaw crusher (such as PE series or JC series), the core of the production line, responsible for crushing large hard stones to approximately 150-250mm.

• Medium Crushing System: Multi-cylinder hydraulic cone crusher. For hard stones, the cone crusher is the best choice for medium crushing. Its layered crushing principle effectively reduces the content of needle-like and flaky particles, and its wear-resistant parts have a long service life, making it suitable for long-term high-intensity operation.

• Screening System: Circular vibrating screen, responsible for classifying the crushed material according to different particle sizes. Qualified material enters the finished product stockpile, while oversized material is returned to the crusher for re-crushing (forming a closed-loop cycle), ensuring precise and controllable particle size control of the final product.

• Conveying System: Belt conveyor, connecting all equipment to form the material flow channel.

• Environmental Dust Removal System: Pulse jet bag filter, used to control dust generated at crushing, screening, and transfer points, meeting environmental protection requirements.

IV. Core Value of Investing in this Production Line

Investing in a mature 150 tons/hour hard rock crushing production line means you will gain:

• Significant economic benefits: Stable high output capacity is the direct source of profit.

• Low operating costs: Wear-resistant equipment, optimized power consumption, and easy maintenance collectively reduce long-term operating costs.

• Superior product quality: A reasonable process ensures excellent aggregate shape and proper gradation, resulting in strong market competitiveness.

• Long equipment lifespan: Reinforced design specifically for hard rock guarantees the durability of the entire production line.

Conquering hard rock requires core strength. Choosing a high-performance heavy-duty jaw crusher as the vanguard, coupled with a scientifically sound and complete production line process, is the key to achieving efficient 150 tons/hour hard rock crushing. Before investing, it is essential to have in-depth communication with professional equipment suppliers, conduct material testing, and customize solutions to ensure your production line truly becomes a solid fortress for value creation.