PE500x750 Jaw Crusher

In the sand and gravel aggregate and mineral processing sector, limestone crushing production lines with a capacity of 80-100 tons per hour are a classic and in-demand configuration in the market. They can meet the capacity requirements of small and medium-sized sand and gravel plants, cement raw material preparation, and highway foundation material supply projects, while achieving a perfect balance between investment costs and operational efficiency.

As a manufacturer with 20 years of experience in mineral processing equipment manufacturing, we deeply understand that the core of a successful production line lies in scientific configuration and durable equipment.

Among various configuration options, the PE500x750 jaw crusheris chosen as the primary crushing equipment due to its robust structure, low price, and easy maintenance, making it the most popular "entry-level" option for this capacity segment.

Why is the PE500x750 jaw crusher the ideal primary crusher for this capacity line?

The PE500x750 is a medium-sized jaw crusher, perfectly designed to meet the 80-100 tons/hour feed and discharge requirements.

• Moderate Feed Size: Maximum feed size up to 425mm, effectively processing raw ore from mines.

• Flexible Discharge Adjustment: The discharge port adjustment range is 50-100mm, which can be flexibly adjusted according to the feed requirements of the secondary crushing equipment, creating favorable conditions for subsequent crushing.

• Balanced Power Configuration: Typically equipped with a 55-75kW motor, ensuring sufficient crushing force while controlling energy consumption and economical operating costs.

• Exceptional Stability: As a company with 20 years of experience, we understand that equipment stability is the lifeline of our customers' production. The PE series jaw crusher uses a high-quality cast steel frame, high-manganese steel jaw plates, and a heavy-duty eccentric shaft, with a simple and reliable structure that can continuously withstand the impact and wear of limestone crushing.

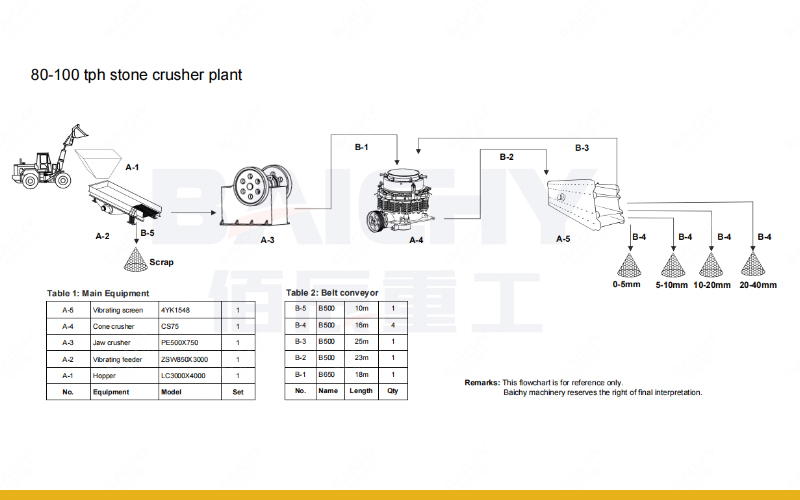

Recommended Core Configuration for an 80-100t/h Limestone Crushing Production Line

A complete production line requires more than just one jaw crusher. Based on the PE500x750 as the primary crusher, we recommend the following efficient and consistent configuration scheme to ensure smooth system operation and excellent finished product particle shape.

| Process | Equipment Recommendation | Model Reference | Main Functions | Remarks |

| Feeding | Vibrating Feeder | GZD-960×3800 | Provides uniform and continuous feeding to the jaw crusher, while simultaneously screening out some soil and impurities | Ensures the jaw crusher operates at full capacity and efficiently, preventing blockages |

| Primary Crushing | Jaw Crusher | PE500x750 | Performs primary coarse crushing of limestone | Core coarse crushing equipment, inexpensive, robust and durable |

| Secondary Crushing | Impact Crusher or Cone Crusher | PF-1210 or PYB-1200 | Medium and fine crushing, crushing the jaw crusher's output to ≤40mm finished aggregate | Impact crushers produce good finished particle shape; cone crushers are more wear-resistant and suitable for limestone with slightly higher silica content |

| Screening | Vibrating Screen | 3YK-1860 | Classifies the crushed material, screening out qualified finished products, and returning large particles for re-crushing | Key equipment determining the final finished product specifications and gradation |

| Conveying | Belt Conveyor | B650-B800 | Connecting various devices to form a production line assembly line. | Length and quantity are customized according to site layout. |

Price of 80-100 t/h Limestone Crushing Production Line Configuration

Production Line Flow Summary: Silo → Vibrating Feeder → PE500x750 Jaw Crusher (Coarse Crushing) → Belt Conveyor → Impact Crusher/Cone Crusher (Medium and Fine Crushing) → Belt Conveyor → Vibrating Screen (Screening) → Finished Product Stockpile. Non-conforming materials are returned by the belt conveyor, forming a closed-loop cycle.

What will you get by choosing our production line?

With twenty years of experience, we offer far more than just a "low-priced" piece of equipment; we provide a complete, cost-effective solution:

1. Customized Design: We provide the optimal process layout based on your raw material characteristics, site conditions, and finished product requirements.

2. In-house Production of Core Equipment, Controllable Quality: Key equipment such as jaw crushers and impact crushers are all manufactured in-house, controlling materials and processes from the source to ensure stable quality.

3. Genuine Cost Advantage: Integrating R&D, production, and sales, we reduce intermediate links, passing the savings on to our customers and achieving both low prices and reliable quality.

4. Full-Cycle Service Support: From installation guidance and commissioning training to spare parts supply and after-sales response, we provide comprehensive support, ensuring your peace of mind.

An 80-100 ton/hour limestone crushing line is a solid step towards a successful business. Choosing a production line centered on the tried-and-tested PE500x750 jaw crusher is choosing a low-risk, high-return, and stable investment path. With twenty years of experience and craftsmanship, we are ready to assist you in creating a brilliant future together.