In modern mining and construction aggregate production, mobile crushing plants have become core equipment for improving operational efficiency and reducing operating costs. As a manufacturer with 20 years of professional experience in mining crushing equipment, we have in-depth knowledge of various mining scenarios worldwide and understand the specific requirements of different working conditions for crushing equipment. This article will focus on analyzing the configuration scheme of mobile crushing plants with a processing capacity of 100-150 tons/hour, particularly the technical characteristics and application scenarios of mobile jaw crushers and impact crushers.

The biggest advantage of mobile crushing plants lies in their superior flexibility—the equipment can be directly deployed to the material site, achieving "crushing on the go, production on-site," completely solving the traditional pain points of fixed production lines such as site limitations, high infrastructure costs, and long material transportation distances. For small and medium-sized mines, urban construction waste recycling, and highway and railway construction projects, mobile crushing solutions have become the most economically efficient choice.

Mobile Jaw Crusher vs. Mobile Impact Crusher: Core Technology Comparison

In the processing range of 100-150 tons/hour, mobile jaw crushers and mobile impact crushers are the two most mainstream configuration choices, each with its own emphasis in working principle, output particle shape, and applicable materials.

Mobile jaw crusher

Mobile impact crusher

Mobile jaw crushers utilize a "V"-shaped crushing chamber and the squeezing principle of the moving jaw plates, featuring a large crushing ratio, robust structure, and strong capacity for handling high-hardness materials. They are particularly suitable for primary crushing, easily handling high-hardness materials such as granite, basalt, and river pebbles, making them the "iron fist" of primary crushing in mines.

Mobile impact crushers utilize a high-speed rotating rotor to drive hammers to impact materials, and through multiple collisions of the impact plates, achieve a combined crushing effect of "stone-on-stone" and "stone-on-iron." Their output particle shape is excellent, mostly cubic, with low needle-like and flaky content, making them particularly suitable for producing high-grade building aggregates and sand and gravel.

| Comparison Items | Mobile Jaw Crusher | Mobile Impact Crusher |

| Working Principle | Extrusion Crushing | Impact Crushing |

| Applicable Material Hardness | High Hardness Materials (Compressive Strength ≤320MPa) | Medium to Low Hardness Materials (Compressive Strength ≤350MPa, but more suitable for ≤250MPa) |

| Discharge Particle Shape | General, mostly needle-like and flaky | Excellent, cubic particle shape |

| Product Particle Size Adjustment | Shim adjustment, relatively fixed range | Hydraulic or mechanical adjustment, flexible range |

| Processing Capacity (100-150t/h configuration) | Stable, sensitive to material moisture | Not sensitive to material moisture, prone to clogging when high moisture content |

| Wear Parts Consumption | Low, long jaw plate life | High, hammer and impact plate need to be replaced regularly |

| Typical Application Scenarios | Primary crushing in mines, quarry head crushing |

Scenario-based Configuration Solutions: Matching Your Actual Needs

Solution 1: Single Mobile Jaw Crusher Solution Suitable for mines producing primary aggregates with high material hardness. For example, a mobile unit consisting of a feeder, jaw crusher, and vibrating screen can directly perform coarse crushing at the mining face, with an adjustable output particle size range of 80-200mm. This option has relatively low investment and simple equipment maintenance, making it particularly suitable for the production of infrastructure fill materials where particle shape requirements are not stringent.

Option Two: Single Mobile Impact Crusher Solution Suitable for crushing and shaping medium-to-low hardness materials, especially for projects requiring the production of high-quality materials such as commercial concrete aggregates and asphalt aggregates. The impact crusher's "more crushing, less grinding" characteristic effectively reduces subsequent sand making energy consumption, and its particle shape optimization capability directly improves product selling price and market competitiveness.

Option Three: Combined Unit Solution (Jaw Crusher + Impact Crusher) For comprehensive projects with strict processing capacity requirements and perse product needs, a two-stage mobile production line can be used, with a mobile jaw crusher as the primary crusher and a mobile impact crusher as the secondary crusher. The two are connected by a mobile belt conveyor, forming a flexible "mobile crushing plant" capable of producing a full range of products from coarse to fine aggregates, offering the strongest adaptability to market changes.

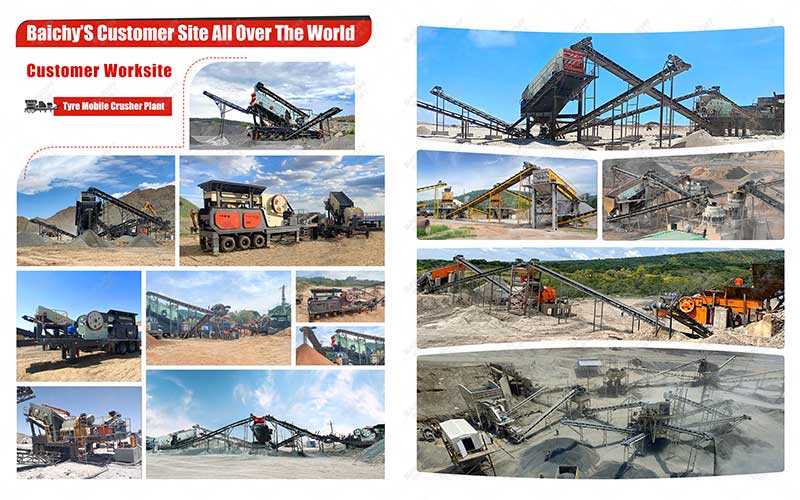

20 Years of Global Service Experience from a Professional Manufacturer

We have been deeply involved in the mining crushing industry for two decades, possessing a profound understanding of the unique challenges posed by different regions and mineral types. From the humid and rainy environment of Southeast Asia to the arid and dusty conditions of the Middle East, from the frigid climate of Northern Europe to the infrastructure limitations of Africa, our mobile crushing plants are specifically designed and reinforced.

Our scenario-based services include:

• Preliminary Site Survey: Engineers conduct on-site investigations of material characteristics, site conditions, power supply, etc., to provide customized solutions.

• Modular Design: Equipment modules can be flexibly adjusted according to transportation restrictions (container size, road weight limits).

• Intelligent Control System: Equipped with a PLC automatic control system and remote monitoring module, enabling fault early warning and capacity optimization.

• Global Spare Parts Network: Spare parts warehouses are established in major mining areas to ensure the fastest possible availability of wear-resistant parts and technical support.

• Operation Training: Multilingual operation manuals and on-site training are provided to ensure that customer teams are proficient in equipment operation and maintenance.

ROI Analysis: Why Choose a Processing Capacity of 100-150 Tons/Hour?

This processing range is considered the "golden capacity range" for medium-sized projects. It meets the actual output needs of most mines and engineering projects while avoiding the waste of idle equipment caused by excessive investment. Based on 10 hours of operation per day, the monthly processing capacity can reach 30,000-45,000 tons, sufficient to support the operational needs of a medium-sized sand and gravel plant or mining project.

From an investment return perspective, the rapid relocation capability of mobile crushing plants significantly shortens project preparation time. Production can typically begin 3-7 days after equipment arrival, resulting in a significantly shorter capital recovery cycle compared to fixed production lines. Furthermore, with increasingly stringent environmental policies, the enclosed design and dust removal system configuration of mobile equipment easily meet local environmental requirements, avoiding losses due to production stoppages caused by non-compliance.

Choosing the Right Mobile Crushing Partner

Choosing a mobile crushing plant is not just about choosing equipment, but also about choosing a long-term partner. We are committed to providing "full lifecycle" service support to every customer, from solution design, installation and commissioning, operation and maintenance to final equipment upgrades, always facing challenges together and sharing the value of success.

Whether you're dealing with hard granite crushing or need to produce high-quality manufactured sand, our technical team can configure the most cost-effective and efficient 100-150 tonnes/hour mobile crushing solution for you. Contact our international business department for customized solutions and success stories tailored to your project.