As a mineral processing equipment manufacturer with 20 years of industry experience, we deeply understand the importance of equipment reliability and efficiency in harsh operating conditions such as mines, quarries, and construction aggregate production. Today, we introduce one of our mature and reliable core products—the Baichy 30x42 (750x1060mm) PE series primary jaw crusher. It is not only the first line of defense on the production line but also the key to ensuring smooth and efficient subsequent processes.

Why is the PE-750x1060 a wise choice for primary crushing?

In the crushing process, primary crushing (coarse crushing) bears the heavy responsibility of processing large pieces of raw ore and determining their initial particle size. Our PE-750x1060 jaw crusher is designed specifically for this purpose. Its design essence lies in its simple structure, reliable operation, and convenient maintenance, and it can withstand high-intensity impacts and wear.

Exceptional Feeding Capacity: Its 750mm x 1060mm feed opening easily handles large rocks up to approximately 630mm in size, laying the foundation for high output.

Profound Manufacturing Expertise: 20 years of experience have allowed us to refine our casting processes, moving jaw assembly design, and bearing selection, ensuring the long-term stability of the equipment under heavy loads.

Wide Applicability: Whether it's hard rocks like granite, basalt, and river pebbles, or medium-hardness materials like limestone and slag, it can handle them all with ease, making it a true rock crusher.

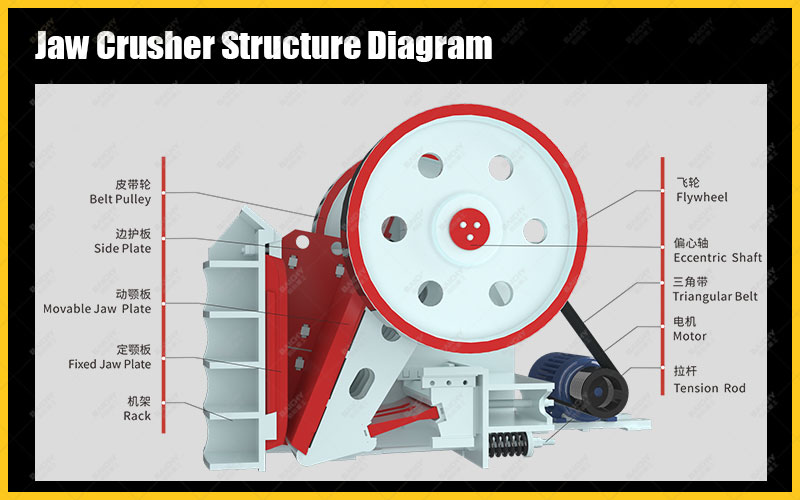

Structural diagram of a jaw crusher

Core Design and Technical Features Analysis

1. Optimized Crushing Chamber Shape: Adopting a V-shaped symmetrical crushing chamber design, the actual feed opening width matches the nominal size more closely, eliminating dead zones and effectively improving crushing efficiency and capacity.

2. High-Strength Structural Components

Frame: Constructed from high-quality steel plates and stress-relieved, it boasts high rigidity and is not easily deformed. Jaw Plates: The moving and fixed jaw plates are made of high-manganese steel, offering excellent impact and wear resistance, and a long service life.

Eccentric Shaft: Machined from large forgings and inspected for flaws, this is the core component for power transmission, ensuring smooth and reliable operation.

3. Reliable Adjustment and Protection Devices

Discharge Port Adjustment: Adjustable by adding or removing shims or using wedges, typically within a range of 80-200mm, allowing for flexible control of product particle size.

Iron Overload Protection: The toggle plate not only transmits force but also acts as a mechanical fuse, preferentially breaking upon encountering uncrushable objects (such as iron blocks) to protect other core components of the main unit.

Key Performance Parameters Overview

The table below clearly shows the main technical parameters of the PE-750x1060 model for your reference when selecting a machine:

| Parameter Item | Specification/Value |

| Model | PE-750x1060 |

| Inlet Size (mm) | 750 x 1060 |

| Maximum Feed Particle Size (mm) | ≤ 630 |

| Discharge Port Adjustment Range (mm) | 80 - 200 |

| Processing Capacity (t/h) | 110 - 320 (depending on discharge port and material hardness) |

| Spindle Speed (r/min) | ~250 |

| Motor Power (kW) | 90 - 110 |

| Equipment Dimensions (L x W x H, mm) | Approx. 2660 x 2430 x 2800 |

Added Value from Two Decades of Experience

Twenty years of manufacturing and service experience allow us to offer more than just a piece of equipment:

Mature Process Support: We can provide reasonable production line configuration recommendations based on your material samples and expected output.

Sustainable Spare Parts Supply: We ensure a long-term supply of core wear parts (such as jaw plates and toggle plates), guaranteeing your production continuity.

Global Service Network: Our team of engineers can provide installation guidance, commissioning, and operation training to customers worldwide.

Summary

The Baichy PE-750x1060 jaw crusher, with its classic structure, robust construction, and ease of maintenance, has become a trusted primary crushing solution for numerous quarries and mining projects worldwide. It embodies our 20 years of unwavering pursuit of reliability and is the solid foundation for your efficient crushing operations.

If you are looking for a coarse crushing machine that can stand the test of time and balances efficiency and cost, the PE-750x1060 is definitely worth your consideration.